Abstract

Aluminum alloys find application in aerospace, automobile, and structural sectors. However, these alloys are susceptible to corrosion attack in chloride environments. Introducing a second species on the surface by surface composite fabrication can be a way to increase the corrosion resistance of the aluminum alloys. Here, we present corrosion studies on aluminum matrix surface composites fabricated using friction stir processing. The reinforcement of Mo particles is considered with varying percentage and distribution in the surface composite. The particle content and distribution are analyzed using SEM–EDS and optical image analysis. Based on the potentiodynamic polarization analysis, the surface composites exhibit improved corrosion resistance with higher corrosion potential and lower corrosion rate. Increase in corrosion resistance is observed for higher Mo content with homogenous distribution. While the base alloy exhibit mixed corrosion behavior, the surface composites show charge-transfer controlled corrosion behavior in the Electrochemical Impedance Spectroscopy. Reduced pitting in the Mo-rich areas is confirmed by microscopic analysis of the corroded material.

Similar content being viewed by others

References

Z.Y. Ma, Friction Stir Processing Technology: A Review, Metall. Mater. Trans. A., 2008, 39, p 642–658.

G. Šekularac, and I. Milošev, Corrosion of Aluminium Alloy AlSi7Mg0.3 in Artificial Sea Water with Added Sodium Sulphide, Corros. Sci., 2018, 144, p 54–73.

M. Liang, R. Melchers and I. Chaves, Corrosion and Pitting of 6060 Series Aluminium After 2 years Exposure in Seawater Splash, Tidal and Immersion Zones, Corros. Sci., 2018, 140, p 286–296.

L.A.B. Mabhali, S.L. Pityana and N. Sacks, Laser Surface Alloying of Aluminium AA1200, Mol. Cryst. Liq. Cryst., 2012, 555, p 138–148.

R.M. Miranda, J. Gandra, and P. Vilaca, Surface Modification by Friction Based Processes, Mod. Surf. Eng. Treat., INTECH Open science, 2013, p 1–20.

K. Yang, W. Li, Y. Xu and X. Yang, Using Friction Stir Processing to Augment Corrosion Resistance of Cold Sprayed AA2024/ Al2O3 Composite Coatings, J. Alloys Compd., 2018, 774, p 1223–1232.

C.M. Abreu, M.J. Cristóbal, R. Figueroa and G. Pena, Influence of Molybdenum ion Implantation on the Localized Corrosion Resistance of a High Strength Aluminium Alloy, Corros. Sci., 2012, 54, p 143–152.

N. Saunders, The AI-Mo System, J. Phase Equilibria., 1997, 18, p 370–378.

A. Almeida, F. Carvalho, P.A. Carvalho and R. Vilar, Laser Developed Al-Mo Surface Alloys: Microstructure, Mechanical and Wear Behaviour, Surf. Coat. Technol., 2006, 200, p 4782–4790.

M.A. McMahon, K.G. Watkins, W.M. Steen, R. Vilar, and M.G.S. Ferreira, Laser Surface Alloying of Aluminium 2014 Alloy with Mo for Enhanced Corrosion Resistance, in: J. Mazumder (Ed.), Laser Process. Surf. Treat. Film Depos., 1996, p 337–358.

D. Chen, J. Cai, J. Fang and Z. Chen, Preparation of Al–Mo Intermetallic Powders by Solid–Liquid Reaction Ball Milling, J. Alloys Compd., 2009, 485, p 9–11.

W.C. Rodrigues, F.R.M. Espinoza, L. Schaeffer and G. Knörnschild, A Study of Al-Mo Powder Processing as a Possible Way to Corrosion Resistant Aluminum-Alloys, Mater. Res., 2009, 12, p 211–218.

Y.J. Kwon, I. Shigematsu and N. Saito, Mechanical Properties of Fine-Grained Aluminum Alloy Produced by Friction Stir Process, Scr. Mater., 2003, 49, p 785–789.

A. Arora, A. Astarita, L. Boccarusso and V.P. Mahesh, Experimental Characterization of Metal Matrix Composite with Aluminium Matrix and Molybdenum Powders as Reinforcement, Procedia Eng., 2016, 167, p 245–251.

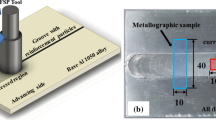

V.P. Mahesh and A. Arora, Effect of Tool Shoulder Diameter on the Surface Hardness of Aluminum-Molybdenum Surface Composites Developed by Single and Double Groove Friction Stir Processing, Metall. Mater. Trans. A., 2019, 50, p 5373–5383.

S. Selvakumar, I. Dinaharan, R. Palanivel, and B. Ganesh Babu, Characterization of Molybdenum Particles Reinforced Al6082 Aluminum Matrix Composites with Improved Ductility Produced Using Friction Stir processing, Mater. Charact., 2017, 125, p 13–22.

A.P.I. Popoola, S.L. Pityana and O.M. Popoola, Laser Deposition of (Cu+Mo) Alloying Reinforcements on AA1200 Substrate for Corrosion Improvement, Int. J. Electrochem. Sci., 2011, 6, p 5038–5051.

C.D. Amato, J.C. Betts and J. Buhagiar, Laser Surface Alloying of an A356 Aluminium Alloy Using Nickel and Ni-Ti-C: A Corrosion Study, Surf. Coat. Technol., 2014, 244, p 194–202.

M. Rahsepar and H. Jarahimoghadam, The Influence of Multipass Friction Stir Processing on the Corrosion Behavior and Mechanical Properties of Zircon-Reinforced Al Metal Matrix Composites, Mater. Sci. Eng. A., 2016, 671, p 214–220.

M. Alishavandi, M.A. Razmjoo Khollari, M. Ebadi, S. Alishavandi, and A.H. Kokabi, Corrosion-Wear Behavior of AA1050/Mischmetal Oxides Surface Nanocomposite Fabricated by Friction Stir Processing, J. Alloys Compd., 2020, 832, p 153964–153975.

V.R. Capelossi, M. Poelman, I. Recloux, R.P.B. Hernandez, H.G. De Melo and M.G. Olivier, Corrosion Protection of Clad 2024 Aluminum Alloy Anodized in Tartaric-Sulfuric Acid Bath and Protected with Hybrid Sol–Gel Coating, Electrochim. Acta., 2014, 124, p 69–79.

M.A. Amin, K.F. Khaled and S.A. Fadl-Allah, Testing Validity of the Tafel Extrapolation Method for Monitoring Corrosion of Cold Rolled Steel in HCl Solutions—Experimental and Theoretical Studies, Corros. Sci., 2010, 52, p 140–151.

V.P. Mahesh, A. Gumaste, N. Meena, J. Alphonsa and A. Arora, Corrosion Behavior of Aluminum Surface Composites with Metallic, Ceramic, and Hybrid Reinforcements Using Friction Stir Processing, Metall. Mater. Trans. B, 2020, 51, p 2131–2146.

K. Surekha, B.S. Murty, and K. Prasad Rao, Comparison of Corrosion Behavior of Friction Stir Processed and Laser Melted AA 2219 Aluminium Alloy, Mater. Des., 2011, 32, p 4502–4508.

D. Song, A. Ma, J. Jiang, P. Lin, D. Yang and J. Fan, Corrosion Behavior of Equal-Channel-Angular-Pressed Pure Magnesium in NaCl Aqueous Solution, Corros. Sci., 2010, 52, p 481–490.

A.J. Trowsdale, B. Noble, S.J. Harris, I.S.R. Gibbins, G.E. Thompson and G.C. Wood, The Influence of Silicon Carbide Reinforcement on the Pitting Behaviour of Aluminium, Corros. Sci., 1996, 38, p 177–191.

M. Yu, M.Y. Ding, H. Ma and H.L. Liao, Microstructure and Corrosion Behavior of Cold-Sprayed Aluminum Alloy/Inconel Composite Coatings, J. Therm. Spray Technol., 2019, 28, p 460–471.

E.M.A. Martini and I.L. Muller, Characterization of the Film Formed on Iron in Borate Solution by Electrochemical Impedance Spectroscopy, Corros. Sci., 2000, 42, p 443–454.

S. Dhillon and R. Kant, Theory for Electrochemical Impedance Spectroscopy of Heterogeneous Electrode with Distributed Capacitance and Charge Transfer Resistance, J. Chem. Sci., 2017, 129, p 1277–1292.

C. op’t Hoog, N. Birbilis, and Y. Estrin, Corrosion of Pure Mg as a Function of Grain Size and Processing Route, Adv. Eng. Mater., 2008, 10, p 579–582.

Acknowledgment

The authors would like to acknowledge the support of Central Instrumentation Facility at Indian Institute of Technology Gandhinagar, and Institute of Plasma Research, Gandhinagar. Two of the authors would like to acknowledge the Board of Research in Nuclear Sciences (BRNS) (Grant: 57/14/05/2019-BRNS) and Science and Engineering Research Board (SERB) (File No: CRG/2018/004944) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no financial or commercial conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahesh, V.P., Alphonsa, J. & Arora, A. Electrochemical Behavior of Aluminum-Molybdenum Surface Composites Developed by Friction Stir Processing. J. of Materi Eng and Perform 30, 8663–8676 (2021). https://doi.org/10.1007/s11665-021-06050-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06050-2