High Pressure Filters 50P Series High Pressure Filters - Mento

High Pressure Filters 50P Series High Pressure Filters - Mento

High Pressure Filters 50P Series High Pressure Filters - Mento

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

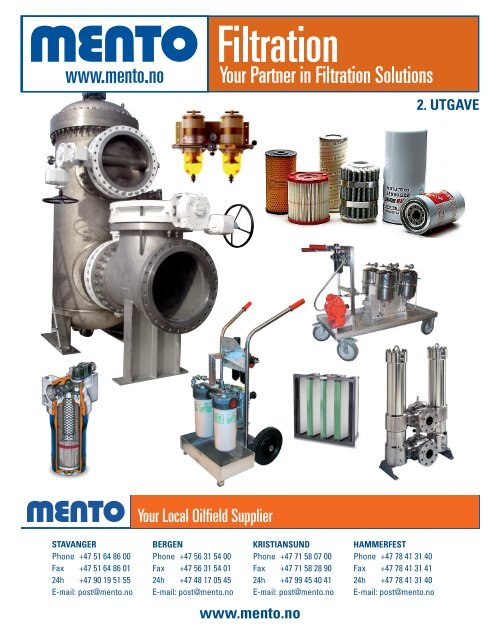

www.mento.no<br />

STAVANGER<br />

Phone +47 51 64 86 00<br />

Fax +47 51 64 86 01<br />

24h +47 90 19 51 55<br />

E-mail: post@mento.no<br />

www.mento.no<br />

BERGEN<br />

Phone +47 56 31 54 00<br />

Fax +47 56 31 54 01<br />

24h +47 48 17 05 45<br />

E-mail: post@mento.no<br />

KRISTIANSUND<br />

Phone +47 71 58 07 00<br />

Fax +47 71 58 28 90<br />

24h +47 99 45 40 41<br />

E-mail: post@mento.no<br />

www.mento.no<br />

HAMMERFEST<br />

Phone +47 78 41 31 40<br />

Fax +47 78 41 31 41<br />

24h +47 78 41 31 40<br />

E-mail: post@mento.no<br />

2. UTGAVE

www.mento.no<br />

PRODUKTKATALOG FILTER<br />

1.0<br />

2.0<br />

3.0<br />

Innledning<br />

• Total Filtration<br />

Management<br />

• Filterfabrikat<br />

• <strong>Mento</strong> Filtration<br />

Væskefiltrering<br />

1.1 Hydraulikk- og<br />

oljefiltrering<br />

1.2 Drivstoffiltrering<br />

1.3 Kjemikalie- og<br />

vannfiltrering<br />

1.4 Analyseutstyr<br />

Prosjektfilter<br />

2.1 Komplette løsninger<br />

2.2 Flammesperre<br />

2.3 Strainere<br />

2.4 Referanser<br />

2.5 Kriterier ved valg av<br />

filterløsninger<br />

2.6 Prosessfilter<br />

systemdata<br />

Luftbehandling<br />

3.1 Filterets oppbygging<br />

3.2 Ventilasjon HVAC<br />

3.3 Turbinfilter<br />

3.4 Støvfilter<br />

3.5 Motorfilter luftinntak<br />

Trykkluft- og<br />

gassfiltrering<br />

4.1 Pneumatic<br />

4.2 Regulator<br />

4.3 Veivhusfilter<br />

Innhold<br />

Nr. Kapittel Side Nr. Kapittel Side<br />

4.0<br />

2<br />

163<br />

187<br />

243<br />

2<br />

4<br />

7<br />

19<br />

23<br />

24<br />

2<br />

5<br />

23<br />

35<br />

47<br />

5<br />

39<br />

83<br />

5.0<br />

6.0<br />

7.0<br />

8.0<br />

Utleie<br />

5.1 Væskefiltrering<br />

og tørking<br />

Generell teknisk<br />

informasjon<br />

6.1 Hvorfor filtrering<br />

6.2 Renhetsklasser<br />

6.3 Viskositet og<br />

overgangstabell<br />

6.4 Vann i olje<br />

6.5 Utstyr for total kontroll<br />

6.6 Gjenge og flensetabell<br />

6.7 Endekapsler stavfilter<br />

6.8 Kritiske kriterier ved<br />

nye filterløsninger<br />

6.9 Hydraulikk<br />

systemdata<br />

<strong>Mento</strong><br />

miljøprodukter<br />

7.0 Index<br />

7.1 Olje og kjemikalie<br />

absorbenter<br />

7.2 Lenser og oljesanering<br />

7.3 Spillberedskap<br />

7.4 Fathåndtering<br />

Andre <strong>Mento</strong><br />

produkter<br />

8.1 Oilfield Supply<br />

8.2 Hoses/Flowline<br />

8.3 Valves<br />

2<br />

2<br />

3<br />

4<br />

6<br />

7<br />

8<br />

10<br />

11<br />

12<br />

2<br />

3<br />

12<br />

13<br />

17<br />

3<br />

4<br />

7

www.mento.no<br />

Total Filtration Management<br />

<strong>Mento</strong> AS er en totalleverandør av filterprodukter. Vårt hovedfokus er på originalproduserte<br />

kvalitetsløsninger for sluttbruker. Godkjent kvalitetssikringssystem sikrer alle sider ved leveransene.<br />

Kunde<br />

Service Avtaler<br />

Kompetanse<br />

Filterløsninger Logistikk Sortiment Ettermarked<br />

Kunde<br />

<strong>Mento</strong> AS er en salgsorganisasjon som daglig<br />

assisterer kunder med informasjon og optimale<br />

løsninger innen filtrering. Vårt mål er å skape<br />

merverdi og god lønnsomhet for alle parter.<br />

Service<br />

Dette er den daglige kontakten du har med <strong>Mento</strong><br />

AS - fra personene som besvarer forespørsler og<br />

telefon, til de som sikrer at rett vare kommer frem til<br />

rett tid og sted.<br />

Avtaler<br />

Sikrer og forenkler kundens tilgang på filter.<br />

Langtids rammeavtaler med mange store og<br />

viktige aktører i markedet, samt lagerhold, skaper<br />

sikkerhet hos våre kunder om at <strong>Mento</strong> AS vil være<br />

den beste samarbeidspartner også i fremtiden.<br />

Kompetanse<br />

<strong>Mento</strong> AS har vært en viktig leverandør i markedet<br />

for filter siden 1971. I denne perioden har vi tilegnet<br />

oss unik erfaring og god kontakt med produsenter<br />

verden over. <strong>Mento</strong> holder jevnlig kurs for å sette<br />

fokus på viktigheten av filtrering.<br />

Total Filtration Management<br />

Logistikk<br />

<strong>Mento</strong> AS har høy fokus på logistikk. Dette skal<br />

sikre rask og korrekt håndtering av varer som går<br />

inn og ut av våre varehus.<br />

Filterløsninger<br />

<strong>Mento</strong> AS er en total samarbeidspartner av filter<br />

løsninger i eksisterende og nye prosjekt. Med<br />

vår egen prosjekt avdeling og utvalgte kvalitets<br />

leverandører sikrer vi optimale teknologiske<br />

løsninger.<br />

Ettermarked<br />

<strong>Mento</strong> er en av Skandinavias største leverandør<br />

av filter med over firehundrede merkenavn i<br />

vårt sortimang.Vi har siden 1971 etablert et godt<br />

utbygd logistikknettverk mot produsenter og lokalt<br />

lagerhold hos <strong>Mento</strong> avdelingene i Norge. Dette<br />

sikrer våre kunder rask respons, riktig vare til<br />

konkurransedyktige betingelser.<br />

Sortiment<br />

<strong>Mento</strong> har med vår erfaring, database og<br />

kontaktnett mulighet til å fremskaffe alle typer filtre<br />

og løsninger. Hvis ikke original vare kan fremskaffes<br />

vil en alternativ løsning som oftest kunne tilbys.

www.mento.no<br />

Filterfabrikat<br />

<strong>Mento</strong> har over 400 forkjellige<br />

filterfabrikat, dette er et utvalg

www.mento.no<br />

A<br />

AAF<br />

AC DELCO<br />

ALLISON<br />

ALTAIR<br />

AMA<br />

AMAZON<br />

AMC<br />

AMETEC<br />

ARGO<br />

ATLAS COPCO<br />

B<br />

BALDWIN<br />

BALSTON<br />

BARDEX<br />

BAUER<br />

BENNEX<br />

BETEX<br />

BOLL KIRCH<br />

BOSCH<br />

BUTECH<br />

C<br />

CAMFIL<br />

CARDEV<br />

CATERPILLAR<br />

CAV<br />

CJC<br />

COOPER<br />

CROSBY<br />

CROSLAND<br />

CUMMINS<br />

CUNO<br />

D<br />

DANFOSS<br />

DELBAG<br />

DEMAG<br />

DEUTZ<br />

DETROIT<br />

DOLLINGER<br />

DOMNICK HUNTER<br />

DONALDSON<br />

E<br />

EUROMATE<br />

EUROPAFILTER<br />

EPPENSTEINER<br />

F<br />

FACET<br />

FAIREY ARLON<br />

FARR<br />

FAUDI<br />

FILTERITE<br />

FINN<br />

FIRTOP<br />

FLEETGUARD<br />

FRAM<br />

G<br />

GENERAL ELECTRIC<br />

GFSA<br />

H<br />

HANKINSON<br />

HATZ<br />

HEADLINE<br />

HENGST<br />

HILCO<br />

HYDAC<br />

HYTREX<br />

Filterfabrikat<br />

I<br />

INGERSOLL-RAND<br />

INDUFIL<br />

INTERNORMEN<br />

IVECO<br />

K<br />

KNECHT<br />

KOOMEY<br />

L<br />

LINDE<br />

M<br />

MAHLE<br />

MANN<br />

MECMAN<br />

MITSUBISHI<br />

MOTORCRAFT<br />

MP<br />

MTU/MERCEDES<br />

N<br />

NISSAN<br />

NORCLEAN<br />

NORGREN<br />

NORMANN<br />

NYTAL<br />

P<br />

PALL<br />

PARKER<br />

PECO<br />

PERKINS<br />

PLENTY<br />

POROUS MEDIA<br />

PREMABERG<br />

PURIFINER<br />

PUROLATOR<br />

R<br />

RACOR<br />

ROLLS ROYCE<br />

S<br />

SABB<br />

SCANIA<br />

SCHROEDER<br />

SEPAR<br />

SHAFFER<br />

SIEMENS<br />

SOFIMA<br />

STAUFF<br />

T<br />

TOYOTA<br />

U<br />

UCC<br />

ULTRAFILTER<br />

V<br />

VELCON<br />

VICKERS<br />

VILEDON<br />

VOKES<br />

VOLVO<br />

W<br />

WARTSILA<br />

WILDEN<br />

WILKERSON<br />

WORTHINGTON<br />

Y<br />

YANMAR<br />

Reg. nr: 21859 Reg. nr: 10050552 NS-EN ISO 9001:2000 No. 205 NE-EN ISO 14001:2004 No. 067

www.mento.no<br />

Kristiansund<br />

Bergen<br />

Stavanger<br />

Hammerfest<br />

STØRST I NORGE

www.mento.no<br />

HYDRAULIKKFILTER<br />

• Høytrykksfilter • Mellomtrykksfilter • Lavtrykksfilter<br />

• Returfilter • Pustefilter for tank • "Off-Line" filter<br />

MOTORFILTER<br />

• Luftfilter • Drivstoffilter<br />

• Oljefilter • Transmisjonsfilter<br />

• Veivhusfilter<br />

VÆSKEFILTER<br />

• Filterhus fra 1/2” til 48” • Plisserte element<br />

• Materialkvalitet og tykkelse • Spunnet element<br />

etter spesifikasjoner • Aktivt kull element<br />

• Filterelement for alle væsketyper • Membranfiltrering<br />

• BAG-filter<br />

AUTOMATFILTER<br />

• For væskefiltrering • Filtrering ned til 10 micron<br />

• Selvrensende strainer • Sentrifugefilter<br />

• Automatisk disc-membranfilter • Størrelse og materialkvalitet etter spesifikasjoner<br />

GASSFILTER<br />

• Filter for alle typer gasser<br />

• Flertrinns separator for fjerning av oljedamp og vann fra gasser<br />

• Coalescerløsninger

www.mento.no<br />

OLJE- OG VANNUTSKILLERE<br />

• Separerer olje fra vann<br />

• Møter høyeste miljøkrav - 5 ppm<br />

TRYKKLUFTFILTER OG TØRKERE<br />

• Høyeffekt-/kjøletørkere Fjerner:<br />

• Trykkluft- og gassfiltrering • Olje- og vannaerosoler<br />

• Instrumentluftfilter • karbondioksid og sure gasser<br />

• Steril luftfiltrering • Faste partikler<br />

• Pusteluftfiltrering • Oljedamp, lukt og smaksstoffer<br />

• Membranfiltrering • Karbonmonosid<br />

MENTO FILTER<br />

• Forfilter til ventilasjon og gassturbin • Rustfrie rammer<br />

• Spesielt beregnet til forfilter luft • Produsert etter mål<br />

• Filtreringsgrad; EU2 til EU5<br />

VENTILASJON- OG LUFTFILTER<br />

• Bag/tube filter • Kompaktfilter<br />

• Posefilter • Filterduk, kan tilskjæres<br />

• Prefilter<br />

OLJERENSEUTSTYR<br />

• "Off-Line" renseunit • Fjerner fritt og bundet vann<br />

• Transportabel eller fastmontert løsning • Fjerner fri og oppløst luft<br />

• Kan leveres med utstyr som partikkelteler, Flowmeter, luft- eller elektrisk pumpe

www.mento.no<br />

Norges største varehus<br />

innen filterprodukter.<br />

Trygghet; 40 år i bransjen.<br />

Stavanger +47 51 64 86 00<br />

Kristiansund +47 71 58 07 00<br />

Bergen +47 56 31 54 00<br />

Hammerfest +47 78 41 31 40<br />

E-post: post@mento.no | www.mento.no<br />

<strong>Mento</strong> Filtration: versjon 01_2009 • artdirector.no

Filtration<br />

www.mento.no HYDRAULIC • OIL • FUEL • CHEMICALS • WATER • AIR TREATMENT • RENTAL<br />

1.0<br />

Væskefiltrering<br />

1.1 Hydraulikk- og oljefiltrering 2<br />

1.1.1 Lavtrykk filterhus opp til 20 bar 5<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar 17<br />

1.1.3 Høytrykksfilter 120 - 1400 bar 33<br />

1.1.4 Rustfrie høytrykksfilter 65<br />

1.1.5 Returfilter 89<br />

1.1.6 Sugefilter 115<br />

1.1.7 Pustefilter 129<br />

1.1.8 Sideløps-/bypassfiltrering 141<br />

1.2 Drivstoffiltrering 163<br />

1.3 Kjemikalie- og vannfiltrering 187<br />

1.3.1 Automatfilter 193<br />

1.3.2 Prosessfilterhus 207<br />

1.3.3 Prosessfilterelement 227<br />

1.4 Analyseutstyr 243<br />

1

www.mento.no<br />

Hydraulikk- og oljefiltrering<br />

Hydraulikk filtrering – bruksområder:<br />

Returfilter lavtrykk<br />

- ofte tankmontert<br />

Sideløps/bypassfilter<br />

- brukes for å rense<br />

oljen uavhengig av om<br />

systemet opererer.<br />

”Nyrefunksjon”<br />

1. Inntil 80% av alle mekaniske driftsavbrudd i hydraulikkanlegg<br />

kan tilbakeføres til urenheter i oljen.<br />

2. Bruk av originale filterelementer er viktigste parameter<br />

for å sikre optimal levetid for anlegget.<br />

3. Andre viktige parameter å ta hensyn til ved valg:<br />

• Flow • Arbeidstemperatur<br />

• Arbeidstrykk • Rørdimensjon<br />

• Filtreringsgrad • Tilslutning<br />

• Trykkfall • Materialvalg<br />

• Oljetype • Ex/Atex hensyn<br />

1.0 Væskefiltrering<br />

1.1 Hydraulikk- og oljefiltrering<br />

Pustefilter<br />

- hindrer vann og<br />

urenheter i å komme<br />

inn via tankluftingen<br />

Suge filter element<br />

- beskytter pumpen<br />

Trykkfilter<br />

De viktigste filtrene i<br />

systemet – beskytter<br />

kritiske komponenter<br />

2

www.mento.no<br />

Returfilter og trykkfilter<br />

• Lavtrykkfilter opptil 20 bar<br />

• Mellomtrykkfilter 20-120 bar<br />

• Høytrykkfilter 120 bar og oppover<br />

Trykkfilter<br />

Funksjon: Er montert etter hovedpumpe og skal<br />

beskytte systemkomponentene. Disse filtrene er<br />

normalt hydraulikksystemets viktigste filter.<br />

Designet for fullt systemtrykk og er utstyrt med<br />

høykvalitets filter element. Kan være utstyrt med<br />

"by-pass" og trykkfalls indikator.<br />

Returfilter<br />

Funksjon: Returstrømmen fra hydraulikksystemet<br />

blir filtrert før retur til reservoar. Hjelper til å holde<br />

oppe kvaliteten på oljen og forlenger levetiden på<br />

trykkfiltrene. Er oftest mye billigere enn trykkfiltrene,<br />

og er ikke designet for fullt designtrykk.<br />

Blir vanligvis levert tankmontert men kan også<br />

leveres linjemontert.<br />

Filteringsgrad ned til 1 micron.<br />

Duplexløsninger med og uten bypass.<br />

Elektrisk og visuell indikator.<br />

1.0 Væskefiltrering<br />

1.1 Hydraulikk- og oljefiltrering<br />

3

www.mento.no<br />

Pustefilter<br />

T.R.A.P. Breathers arrest 1.0 moisture Væskefiltrering and free your budget.<br />

1.1 Hydraulikk- og oljefiltrering<br />

And it has a way of sneaking into<br />

your hydraulic circuits. Unless<br />

you have a Donaldson T.R.A.P. <br />

Breather standing guard over<br />

your system.<br />

NO moisture slips by Donaldson’s Thermally Reactive<br />

Advanced Protection (T.R.A.P.). In fact, it removes moisture<br />

at relative humidity levels as low as 15%! T.R.A.P. filtration<br />

technology reacts instantly to thermal conditions, blocking<br />

moisture completely.<br />

T.R.A.P. Breathers last up to 50% longer!<br />

Brand X<br />

Brand Y<br />

Donaldson T.R.A.P. Breather<br />

0 500 1000 1500 2000 2500 3000<br />

The patented T.R.A.P. filtering material regenerates its water-holding<br />

capacity, leading to a much longer service life. In competitive testing,<br />

T.R.A.P. Breathers performed beyond 3,000 cycles, while silica gel<br />

breathers lost efficiency at less than 2,000 cycles.<br />

“The T.R.A.P. Breathers last longer. They’re more durable.”<br />

– Florida<br />

Compare<br />

Service life<br />

Filtration<br />

Other Advantages<br />

T.R.A.P. Technology<br />

Extended Life (exhales moisture<br />

and refreshes its holding capacity<br />

on each cycle).<br />

Reacts instantly to conditions in the<br />

hydraulic circuit, creating a moisture<br />

barrier without impeding airflow.<br />

Reduced man-hours.<br />

Thermally reactive barrier that<br />

removes moisture at relative humidity<br />

levels as low as 15%.<br />

Superior moisture blocking and<br />

particulate filtration down to<br />

3 microns at 97%.<br />

Will not freeze in winter.<br />

T.R.A.P. Breathers from Donaldson are the ONLY breathers on<br />

the market that literally strip moisture vapor from intake air and<br />

exhale the moisture back to the atmosphere on the outflow cycle.<br />

The filter continuously regenerates its water holding capacity!<br />

T.R.A.P. Breathers last longer. So will your budget.<br />

As illustrated to the right, T.R.A.P. Breathers actually exhale<br />

the moisture back out, which means you won’t need to change<br />

the breather due to water saturation … unlike desiccant filters<br />

that require frequent change-out. Like the name suggests,<br />

it TRAPS water before it gets in, yet doesn’t restrict air flow,<br />

and lets your hydraulic reservoir BREATHE.<br />

Funksjon: står montert på tank/reservoir for å hindre smuss og fuktighet fra å komme inn i<br />

tanken. Finnes i ulike alternativer.<br />

Bypassfilter<br />

Desiccant <strong>Filters</strong><br />

Shorter life (due to saturation of<br />

filtering material), leading to frequent<br />

replacement.<br />

Requires extended exposure to the air stream<br />

before absorption begins. Restricts airflow.<br />

Hvis olje i et system er blitt forurenset av vann eller partikler kan det være en løsning å behandle<br />

oljen i stedet for å kjøpe Effectiveness ny.<br />

Oftest har oljen like god eller bedre kvalitet som ny etter behandling med filterenhet eller purifier.<br />

Når disse rense metodene Maintenance brukes costs kan systemet være i drift når behandlingen Increased man-hours. gjøres, og man får<br />

også behandlet den oljen Technology som til enhver tid er ute i systemet. Kontakt Absorbent oss filtering – enten material det that gjelder loses kjøp<br />

holding capacity with each cycle.<br />

eller leie av utstyr for å rense olje – så skal vi finne den beste løsningen for deres behov.<br />

Less effective moisture blocking<br />

and particulate filtration.<br />

Subject to freezing in winter conditions.<br />

Compare T.R.A.P. Breathers and you’ll be impressed. Try T.R.A.P. Breathers and you’ll be convinced!<br />

4

www.mento.no<br />

1.1.1<br />

Lavtrykksfilterhus<br />

opp til 20 bar<br />

5

www.mento.no<br />

6

www.mento.no<br />

1. TECHNICAL<br />

SPECIFICATIONS<br />

1.1 FILTER HOUSING<br />

Construction<br />

The filter consists of a filter head with<br />

built-in bypass valve and a screw-on<br />

filter cartridge.<br />

Standard equipment:<br />

with 1.7 bar bypass valve<br />

1.2 FILTER CARTRIDGES<br />

MG: Cartridge connection thread to<br />

I SO 228<br />

Sealing on inside<br />

( note: the seal on the<br />

0080 MA cartridge is also<br />

on the inside!)<br />

MA: C artridge connection UN thread<br />

Sealing on the outside<br />

gasket gasket<br />

1.3 FILTER SPECIFICATIONS<br />

1.4 SEALS<br />

NBR (= Perbunan)<br />

1.5 MOUNTING<br />

As inline filter<br />

1.6 SPECIAL MODELS AND<br />

ACCESSORIES<br />

without bypass valve or with other<br />

bypass cracking pressures<br />

1.7 SPARE PARTS<br />

See Original Spare Parts List<br />

1.8 CERTIFICATES AND APPROVALS<br />

On request<br />

1.9 COMPATIBILITY WITH<br />

HYDRAULIC FLUIDS ISO 2943<br />

Hydraulic oils H to HLPD DIN 51524<br />

Lubrication oils DIN 51517, API,<br />

ACEA, DIN 51515, ISO 6743<br />

Compressor oils DIN 51506<br />

Biodegradable operating fluids VDMA<br />

24568 HETG, HEES, HEPG<br />

Non-flam operating fluids HFA, HFB,<br />

HFC and HFD<br />

Operating fluids with high water<br />

content (>50% water content) on<br />

request<br />

Symbol for hydraulic systems<br />

Nominal pressure 8 bar<br />

Temperature range - 30 °C to +100 °C<br />

<strong>Pressure</strong> setting of clogging indicator: p a T ype E: 0 to 16 bar<br />

Type F: 1 .5 or 2 bar<br />

Type UE: 0 to -1.0 bar<br />

Type UF: -0.2 bar<br />

Type of clogging indicator VMF (return line pressure indicator)<br />

Material of filter head A luminium<br />

Material of filter cartridge Sheet steel<br />

Cracking pressure of bypass valve 1.7 bar (standard)<br />

MF<br />

80<br />

MF<br />

160<br />

MF<br />

180<br />

MFD<br />

160<br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

Spin-On Filter MF/MFD<br />

up to 300 l/min, up to 8 bar<br />

MFD<br />

180<br />

7

www.mento.no<br />

2. MODEL CODE (ALSO ORDER EXAMPLE)<br />

2.1 COMPLETE FILTER<br />

Filter type<br />

MF (all sizes; 1 filter cartridge)<br />

MFD (size 160 and 180; 2 filter cartridges)<br />

Filter material of element<br />

BN Betamicron ®<br />

P Paper (only MF 80 and MF/MFD 160)<br />

Size of filter or cartridge<br />

MF: 80, 160, 180<br />

MFD: 160, 180<br />

Operating pressure<br />

A 8 bar<br />

Type of cartridge connection<br />

G thread to ISO 228 (G1¼)<br />

U UN thread (1-12 UNF, 1½ x 16 UN-2B)<br />

Type and size of port<br />

Type Port Filter size<br />

80 160 180<br />

C G ¾ MF – –<br />

E G1 ¼ – MF MF<br />

F G1 ½ – MFD MFD<br />

Filtration rate in µm<br />

BN 3, 5, 10, 20<br />

P 10<br />

Type of clogging indicator<br />

A steel blanking plug in indicator port<br />

E<br />

F<br />

pressure gauge<br />

pressure switch<br />

pressure indicators<br />

for other clogging indicators<br />

UE<br />

UF<br />

vacuum gauge<br />

vacuum switch<br />

vacuum indicators see brochure no. E 7.050../..<br />

Type code<br />

0<br />

1 - 8 see point 2.4<br />

Modification number<br />

X the latest version is always supplied<br />

Supplementary details<br />

B. bypass cracking pressure (e.g.: B0.2 = 0.2 bar; B0.25 = 0.25 bar; B2 = 2 bar)<br />

KB without bypass valve<br />

2.2 REPLACEMENT CARTRIDGE<br />

Size<br />

0080, 0160, 0180<br />

Type<br />

MG for filters with cartridge connection G (= thread to ISO 228);<br />

paper filter material only (exception: MF 80: 20 BN)<br />

MA for filters with cartridge connection U (= UN thread)<br />

Filtration rate in µm<br />

BN 003, 005, 010, 020 (for MF 80: MA = all filtration ratings; MG = 20 µm)<br />

P 010<br />

Filter material<br />

BN, P<br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

0160 MA 010 BN<br />

2.3 REPLACEMENT CLOGGING INDICATOR VMF 2 F . X<br />

Type<br />

VMF return line pressure indicator<br />

<strong>Pressure</strong> setting<br />

2 (see point 1.3)<br />

Type of clogging indicator<br />

F (see point 2.1)<br />

Modification number<br />

X the latest version is always supplied<br />

MF BN 160 A U E 10 F 1 .X /-KB<br />

8

www.mento.no<br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

2.4 MOUNTING POSITION OF THE CLOGGING INDICATOR<br />

MF 80 MF 160/180 MFD 160/180<br />

For MF filters<br />

Type Mounting position of the Application of Type of Specials<br />

code clogging indicator complete filter indicator<br />

0.X Without clogging indicator, blanking plug in all indicator ports –<br />

1.X Filter inlet: on left Return line filter <strong>Pressure</strong> indicator –<br />

2.X Filter inlet: on right Return line filter <strong>Pressure</strong> indicator –<br />

3.X Filter outlet: on left Suction filter Vacuum indicator Only for sizes 160 and 180, on versions:<br />

- with bypass cracking pressure 0.2 bar (.../-B0.2)<br />

- without bypass valve (.../-KB)<br />

4.X Filter outlet: on right Suction filter Vacuum indicator Only for sizes 160 and 180, on versions:<br />

- with bypass cracking pressure 0.2 bar (.../-B0.2)<br />

- without bypass valve (.../-KB)<br />

5.X Filter inlet & outlet: on left <strong>Pressure</strong> filter <strong>Pressure</strong> and –<br />

vacuum indicator<br />

6.X Filter inlet & outlet: on right <strong>Pressure</strong> filter <strong>Pressure</strong> and –<br />

vacuum indicator<br />

7.X Filter inlet: on right & left Return line filter <strong>Pressure</strong> indicator –<br />

8.X Filter outlet: on right & left Suction filter Vacuum indicator Only for sizes 160 and 180, on versions:<br />

- with bypass cracking pressure 0.2 bar (.../-B0.2)<br />

- without bypass valve (.../-KB)<br />

For MFD filters<br />

Type Mounting position of the Application of Type of Specials<br />

code clogging indicator complete filter indicator<br />

0.X Without clogging indicator, blanking plug in all indicator ports –<br />

1.X Filter inlet: on right Return line filter <strong>Pressure</strong> indicator –<br />

3.X Filter outlet: on right Suction filter Vacuum indicator Only on versions:<br />

- with bypass cracking pressure 0.2 bar (.../-B0.2)<br />

- without bypass valve (.../-KB)<br />

5.X Filter inlet & outlet: on right <strong>Pressure</strong> filter <strong>Pressure</strong> & vacuum indicator<br />

2.5 CARTRIDGE SELECTION TABLE<br />

Filter type MF<br />

Size 80 Cartridge<br />

MF P 80 AGC 10 ... 0080 MG 010 P<br />

MF BN 80 AUC 10 ... 0080 MA 010 BN<br />

MF BN 80 AGC 20 ... 0080 MG 020 BN<br />

Size 160 Cartridge<br />

MF P 160 AGE 10... 0160 MG 010 P<br />

MF BN 160 AUE 3... 0160 MA 003 BN<br />

MF BN 160 AUE 5... 0160 MA 005 BN<br />

MF BN 160 AUE 10... 0160 MA 010 BN<br />

MF BN 160 AUE 20... 0160 MA 020 BN<br />

Size 180 Cartridge<br />

MF BN 180 AUE 3... 0180 MA 003 BN<br />

MF BN 180 AUE 5... 0180 MA 005 BN<br />

MF BN 180 AUE 10... 0180 MA 010 BN<br />

MF BN 180 AUE 20... 0180 MA 020 BN<br />

Filter type MFD<br />

Size 80 Cartridge<br />

– not available<br />

– not available<br />

– not available<br />

Size 160 Cartridge<br />

MFD P 160 AGF 10... 0160 MG 010 P<br />

MFD BN 160 AUF 3... 0160 MA 003 BN<br />

MFD BN 160 AUF 5... 0160 MA 005 BN<br />

MFD BN 160 AUF 10... 0160 MA 010 BN<br />

MFD BN 160 AUF 20... 0160 MA 020 BN<br />

Size 180 Cartridge<br />

MFD BN 180 AUF 3... 0180 MA 003 BN<br />

MFD BN 180 AUF 5... 0180 MA 005 BN<br />

MFD BN 180 AUF 10... 0180 MA 010 BN<br />

MFD BN 180 AUF 20... 0180 MA 020 BN<br />

2.6 CHANGING THE CARTRIDGE<br />

Filter cartridge type MG:<br />

Unscrew filter cartridge (using a strap<br />

wrench, if necessary). Lubricate seal<br />

on the new cartridge. Screw in new<br />

cartridge until contact is made with the<br />

sealing surface. Then hand-tighten.<br />

Check for leakage and tighten further<br />

if necessary.<br />

Filter cartridge type MA:<br />

Unscrew filter cartridge (using a strap<br />

wrench, if necessary). Lubricate new<br />

seal and insert it into the filter head.<br />

Screw in new cartridge until contact is<br />

made with the sealing surface. Then<br />

hand-tighten.<br />

Check for leakage and tighten further<br />

if necessary.<br />

9

www.mento.no<br />

4. DIMENSIONS<br />

MF 80<br />

MF 160/180<br />

port for clogging indicators,<br />

type code 1, 5 or 7<br />

port for clogging indicators,<br />

type codel 2, 6 or 7<br />

port for clogging<br />

indicators,<br />

type code 1<br />

port for clogging<br />

indicators,<br />

type code 2<br />

Ø<br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

/ MG: 145<br />

MA:<br />

/ MG: 188<br />

MA:<br />

port for clogging indicators,<br />

type code 3, 5 or 8<br />

port for clogging indicators,<br />

type code 4, 6 or 8<br />

10

www.mento.no<br />

Spin-on <strong>Filters</strong><br />

Maxiflow <strong>Series</strong><br />

MAX 360 I/min - 10 bar<br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

11

www.mento.no<br />

Specification<br />

Installation Details<br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

Preferred<br />

<strong>Series</strong><br />

MXA<br />

PS<br />

<strong>Series</strong><br />

Maximum working pressure: 10<br />

bar<br />

10<br />

bar<br />

Filter head material: Aluminium<br />

LM24<br />

Aluminium<br />

alloy<br />

Filter bowl material: Steel<br />

Steel<br />

Seal material: Nitrile<br />

Buna<br />

( nitrile)<br />

Operating temperature range: -30°<br />

C to<br />

+ 90°<br />

C<br />

-30°<br />

C to<br />

+ 110°<br />

C<br />

Bypass: Return<br />

line<br />

1.<br />

05<br />

bar<br />

Return<br />

line<br />

1.<br />

5 bar<br />

Suction<br />

line<br />

0.<br />

17<br />

bar<br />

Suction<br />

line<br />

0.<br />

10<br />

bar<br />

No<br />

bypass<br />

option<br />

No<br />

bypass<br />

option<br />

Fluids: Mineral<br />

oils<br />

Mineral<br />

oils<br />

Element media: Microglass III media<br />

Cellulose media<br />

D B<br />

A<br />

20<br />

C<br />

F<br />

Minimum for element<br />

removal<br />

K<br />

M<br />

G<br />

H<br />

ØJ<br />

2 mounting holes<br />

‘L’<br />

Filter selection<br />

To select the correct filter use the appropriate<br />

pressure drop graphs. For details and an example<br />

of how to select the correct filter, see next page.<br />

Type<br />

MXA.8<br />

12PS<br />

MXA.9<br />

22PS<br />

MXA.7<br />

MXA.8/MXA.9*** 12PS/22PS Size 3 MXA.7***<br />

G 3 /4<br />

G1 1 /4<br />

G1 1 /2<br />

19<br />

(0.75)<br />

22<br />

(0.86)<br />

30<br />

(1.18)<br />

28<br />

(1.10)<br />

430<br />

(16.93)<br />

147<br />

(5.79)<br />

165<br />

(6.49)<br />

179<br />

(7.04)<br />

208<br />

(8.19)<br />

179<br />

(7.05)<br />

D<br />

12PS-15<br />

22PS-20<br />

173<br />

(6.81)<br />

187<br />

(7.36)<br />

213<br />

(8.38)<br />

236<br />

(9.29)<br />

214<br />

(8.42)<br />

B<br />

C<br />

A<br />

Element removal<br />

clearance<br />

H<br />

L<br />

95<br />

(3.74)<br />

95<br />

(3.74)<br />

133<br />

(5.24)<br />

133<br />

(5.23)<br />

140<br />

(5.51)<br />

F<br />

A B C D F G H J K L M<br />

97<br />

(3.82)<br />

N/A<br />

129<br />

(5.08)<br />

N/A<br />

N/A<br />

K<br />

Inlet<br />

38<br />

(1.49)<br />

38<br />

(1.49)<br />

50<br />

(1.97)<br />

50<br />

(1.97)<br />

65<br />

(2.56)<br />

94<br />

(3.7)<br />

93<br />

(3.66)<br />

127<br />

(5.0)<br />

130<br />

(5.12)<br />

127<br />

(5.0)<br />

70<br />

123 (4.84)<br />

J<br />

70<br />

102 (4.01) (2.75)<br />

B<br />

Ø54 (2.12)<br />

2 mounting holes<br />

‘L’<br />

F<br />

Ø129<br />

H<br />

88<br />

(3.46)<br />

107<br />

(4.21)<br />

130<br />

(5.12)<br />

N/A<br />

20<br />

(0.79)<br />

D<br />

C<br />

Minimum for<br />

element removal<br />

20<br />

(0.79)<br />

Minimum for<br />

element removal<br />

optional indicators<br />

A 2 ports 1/8” BSPT for<br />

M8 x<br />

1.25 x 16<br />

full depth<br />

M10 x 1.5<br />

12<br />

Circuit symbol<br />

72<br />

(2.83)<br />

N/A<br />

72<br />

(2.83)<br />

N/A

www.mento.no<br />

Full Flow <strong>Filters</strong> for Suction or Return<br />

Maxiflow Filter<br />

PRESSURE DROP CURVES<br />

Size 1 Maxiflow (MXA.8*** <strong>Series</strong>) and 12PS <strong>Series</strong><br />

Δp (bar)<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

Filter Housing<br />

Flow (US GPM)<br />

0 3 5 8 11 13 16 18 21 24 26 29<br />

1.0<br />

0<br />

0 10<br />

20<br />

30<br />

40 50 60 70 80 90 100 110<br />

Flow (l/min)<br />

Filter Housing<br />

31<br />

14.5<br />

11.6<br />

8.7<br />

5.8<br />

2.9<br />

0<br />

120<br />

Size 2 Maxiflow (MXA.9*** <strong>Series</strong>) and 22PS <strong>Series</strong><br />

Δp (bar)<br />

0 5 11 16 21 26 31 37 42 47 53 58<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

Flow (US GPM)<br />

0<br />

0 20 40 60 80<br />

100 120 140 160 180<br />

Flow (l/min)<br />

Size 3 Maxiflow (MXA.7*** <strong>Series</strong>)<br />

Δp (bar)<br />

Filter Housing<br />

200<br />

220<br />

61<br />

5.8<br />

4.4<br />

2.9<br />

1.5<br />

0<br />

240<br />

Flow (US GPM)<br />

0<br />

0.7<br />

13 26 39 53 66 79 92 106<br />

10.2<br />

0.6<br />

8.7<br />

0.5<br />

7.3<br />

0.4<br />

5.8<br />

0.3<br />

4.4<br />

0.2<br />

2.9<br />

0.1<br />

1.5<br />

0<br />

0<br />

0 50 100 150 200<br />

Flow (l/min)<br />

250 300 350 400<br />

Δp (psid)<br />

Δp (psid)<br />

Δp (psid)<br />

Δp (bar)<br />

Δp (bar)<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

The recommended level of the initial pressure drop for low pressure filters is max 0.5 bar.<br />

If the medium used has a viscosity different from 30 cSt, pressure drop over the filter can be estimated as follows :p<br />

= ( p30 x viscosity of medium used) / 30 cSt<br />

Note: All above data is calculated at 30cSt Rel density 0.856.<br />

Δp (bar)<br />

Filter Element<br />

Flow (US GPM)<br />

0 3 5 8 11 13 16 18 21 24 26 29 31<br />

0.5<br />

7.3<br />

10μ Abs<br />

25 Abs<br />

0<br />

0 10<br />

20<br />

30<br />

40 50 60 70 80 90 100 110<br />

Flow (l/min)<br />

0 5 11 16 21 26 31 37 42 47 53 58<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

Filter Element<br />

Flow (US GPM)<br />

10μ Abs<br />

25 Abs<br />

5.8<br />

4.4<br />

2.9<br />

1.5<br />

0<br />

120<br />

64<br />

14.5<br />

0<br />

0 20 40<br />

60<br />

80<br />

100<br />

120 140 160 180 200<br />

220<br />

0<br />

240<br />

Flow (l/min)<br />

0 13 26 39 53 66 79 92<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

Filter Element<br />

Flow (US GPM)<br />

10μ Abs<br />

10 Abs<br />

0<br />

0 50 100 150<br />

200<br />

Flow (l/min)<br />

250 300<br />

350<br />

0<br />

400<br />

11.6<br />

8.7<br />

5.8<br />

2.9<br />

106<br />

11.6<br />

10.2<br />

8.7<br />

7.3<br />

5.8<br />

4.4<br />

2.9<br />

1.5<br />

Δp (psid)<br />

Δp (psid)<br />

Δp (psid)<br />

13

www.mento.no<br />

PREFERRED PRODUCTS TABLE<br />

Type Part Number Description<br />

MXA.8*** & 12PS Return Line <strong>Filters</strong><br />

MXA<br />

PS<br />

MXA<br />

PS<br />

MXA.8551.424<br />

12PS-10BT-V1-R-2-B<br />

MXA.8*** & 12PS Suction Line <strong>Filters</strong><br />

MXA<br />

PS<br />

MXA<br />

PS<br />

MXA.9*** & 22PS Return Line <strong>Filters</strong><br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

Full Flow <strong>Filters</strong> for Suction or Return<br />

Maxiflow Filter<br />

Assembly with Bypass & Dual Visual Indicators<br />

Assembly with Bypass & Gauge Type Visual Indicator<br />

7<br />

10<br />

65<br />

10<br />

Absolute<br />

G 3 /4<br />

14<br />

MAOP Flow Media<br />

Replacement<br />

Ports<br />

(bar) (l/min) Rating Element<br />

MXR.8550<br />

926501<br />

MXA MXA.9561.424 Assembly with Bypass & Dual Visual Indicators G1 MXR.9560<br />

1 3<br />

7 30<br />

/4<br />

Absolute<br />

3 Micron Absolute Filtration for Off-Line System Clean Up<br />

The maxiflow 3 micron absolute elements are ideal for off-line clean up applications. These can be specified for the 9*** and 7*** series return filters.<br />

MXA<br />

PS<br />

PS<br />

MXA<br />

PS<br />

PS<br />

PS<br />

MXA<br />

PS<br />

MXA<br />

PS<br />

MXA.7***<br />

MXA.8511.424<br />

12PS-10CT-V1-R-2-B<br />

12PS-10CT-E2-R-2-B<br />

12PS-10CT-P-R-2-B<br />

MXA.8551.223<br />

12PS-10CT-V1-S-4-B<br />

MXA.8551.023<br />

12PS-10CT-V1-SX-4-B<br />

MXA.9551.424<br />

22PS-10BT-V1-R-2-D<br />

22PS-10BT-E2-R-2-D<br />

MXA.9511.424<br />

22PS-10CT-V1-R-2-D<br />

22PS-10CT-E2-R-2-D<br />

22PS-10CT-P-R-2-D<br />

MXA.9*** & 22PS Suction Line <strong>Filters</strong><br />

MXA.9511.223<br />

22PS-10CT-V2-S-4-D<br />

MXA.9511.023<br />

22PS-10CT-P-SX-4-D<br />

MXA MXA.7551.424 Assembly with Bypass & Visual Indicators G1 MXR.9550 (2)<br />

1 10<br />

7 300<br />

/2<br />

Absolute<br />

MXA MXA.7511.424 Assembly with Bypass & Visual Indicators 7 350 25 Abs<br />

MX.1591.4.10 x 4*<br />

MXA.7*** Suction Line <strong>Filters</strong><br />

MXA MXA.7551.223<br />

MXA.7551.023<br />

MXA MXA.7511.223<br />

MXA.7511.023<br />

Assembly with Bypass & Dual Visual Indicators<br />

Assembly with Bypass & Gauge Type Visual Indicator<br />

Assembly with Bypass & Electrical <strong>Pressure</strong> Indicator<br />

Assembly with Bypass & No Indicator<br />

Assembly with Bypass & Dual Visual Indicators<br />

Assembly with Bypass & Gauge Type Visual Indicator<br />

Assembly without Bypass, with Dual Visual Indicators<br />

Assembly without Bypass, with Gauge Type Visual Indicator<br />

Assembly with Bypass & Dual Visual Indicators<br />

Assembly with Bypass & Gauge Type Visual Indicator<br />

Assembly with Bypass & Electrical <strong>Pressure</strong> Indicator<br />

Assembly with Bypass & Dual Visual Indicators<br />

Assembly with Bypass & Gauge Type Visual Indicator<br />

Assembly with Bypass & Electrical <strong>Pressure</strong> Indicator<br />

Assembly with Bypass & No Indicator<br />

Assembly with Bypass & Dual Visual Indicators<br />

Assembly with Bypass & Gauge Type Visual Indicator<br />

Assembly without Bypass, with Dual Visual Indicators<br />

Assembly without Bypass, with Gauge Type Visual Indicator<br />

Assembly with Bypass & Visual Indicators<br />

Assembly without Bypass with Visual Indicators<br />

Assembly with Bypass & Visual Indicators<br />

Assembly without Bypass with Visual Indicators<br />

7<br />

10<br />

7<br />

10<br />

7<br />

10<br />

7<br />

10<br />

7<br />

10<br />

7<br />

10<br />

7<br />

7<br />

20<br />

160<br />

180<br />

180<br />

160<br />

180<br />

20<br />

48<br />

80<br />

80<br />

25 Abs<br />

10<br />

Nominal<br />

25 Abs<br />

10 Nom<br />

25 Abs<br />

10 Nom<br />

10<br />

Absolute<br />

25 Abs<br />

10<br />

Nominal<br />

25 Abs<br />

10 Nom<br />

25 Abs<br />

10 Nom<br />

10<br />

Absolute<br />

25<br />

Absolute<br />

The Maxiflow <strong>Series</strong> 7*** filters can be specified with additional visual or electrical indicators. Please contact Parker Filtration for details.<br />

Note: Elements marked with an asterisk (*) are only available in 4 element packs.<br />

7<br />

10<br />

70<br />

G 3 /4<br />

G 3 /4<br />

G1 1 /4<br />

G1 1 /4<br />

G1 1 /4<br />

G1 1 /2<br />

G1 1 /2<br />

G1 1 /2<br />

MX.1518.4.10 x 4*<br />

921166<br />

MX.1518.4.10 x 4*<br />

921166<br />

MX.1518.4.10 x 4*<br />

921166<br />

MXR.9550<br />

926503<br />

MX.1591.4.10 x 4*<br />

926502<br />

MX.1591.4.10 x 4*<br />

926502<br />

MX.1591.4.10 x 4*<br />

926502<br />

MXR.9550 (2)<br />

MX1591.4.10 x 4*<br />

(2)

www.mento.no<br />

Spin-On Hydraulic Protection<br />

Elements<br />

Low-<strong>Pressure</strong> Filtration applications for return lines and other low-pressure fluid circuits.<br />

Part No. IN HW3510 IN HW5710 IN HW51110<br />

Flow Rate 15 gpm / 57 lpm 50 gpm / 190 lpm 50 gpm / 190 lpm<br />

Threads 1" – 12 1 1/2" – 16 1 1/2" – 16<br />

Dimensions 3.7D x 5.5L 5.0D x 7.0L 5.0D x 11.0L<br />

<strong>Pressure</strong> 100 PSI / 690 kPa 100 PSI / 690 kPa 100 PSI / 690 kPa<br />

See chart below for mounting head information.<br />

<strong>High</strong>-<strong>Pressure</strong> Filtration applications for pressure locations within the fluid circuit.<br />

Part No. HP60077 HP60080 HP60083 HP60086<br />

Flow Rate 20 gpm 20 gpm 50 gpm 50 gpm<br />

Length Standard Extended Standard Extended<br />

<strong>Pressure</strong> 3000 PSI / 20,690 kPa 3000 PSI / 20,690 kPa 3000 PSI / 20,690 kPa 3000 PSI / 20,690 kPa<br />

Consult factory for ordering assistance.<br />

Mounting Heads<br />

Part No. Head Port Center By-pass Filter<br />

Type Size Thread Setting (PSID) Application<br />

Maximum flow rate for the heads below is 15 gpm / 900 gph and up to 175 PSI / 12.1 bar<br />

IN HH 75503 1 3/4" NPT 1"-12 UN 3 Use with<br />

IN HH 07515 1 3/4" NPT 1"-12 UN 15 3510<br />

IN HH 07525 1 3/4" NPT 1"-12 UN 25 filter<br />

Maximum flow rate for the heads below is 50 gpm / 3000 gph and up to 175 PSI / 12.1 bar<br />

IN HH 125151 2 1 1/4" NPT 1 1/2"-16 UN 15 Use with<br />

IN HH 125251 2 1 1/4" NPT 1 1/2"-16 UN 25 5710<br />

and<br />

IN HH 12515MP2 2 1 1/4" NPT 1 1/2"-16 UN 15 51110<br />

IN HH 12525MP2 2 1 1/4" NPT 1 1/2"-16 UN 25 filters<br />

1 Specify L or R. L provides the standard color-coded bar restriction gauge on the side of the head with the<br />

flow direction going to your left. R has the flow going to the right. See center head illustration, above.<br />

2 MP signifies a multi-port head. The multi-ports are for an optional in-head gauge, such as the IN HG15LF<br />

liquid filled, 1.5" diameter, compound pressure/vacuum gauge (1/8" NPT). See right illustration, above.<br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

Racor water-absorbing hydraulic filters feature<br />

a specially designed media that traps solid<br />

contaminants like dirt and rust and damaging<br />

water. As the element fills with water and plugging<br />

occurs, flow slows and the head goes into a bypass<br />

mode. Water-absorbing spin-on hydraulic filters<br />

are available for virtually any application and are<br />

available in a 10-micron rating. To make monitoring<br />

easy, Racor offers a range of heads with pressure<br />

restriction gauges, including large diameter heads<br />

with standard, color-coded bar gauges.<br />

15

www.mento.no<br />

Water Absorbing Media<br />

1.0 Væskefiltrering<br />

1.1.1 Lavtrykk filterhus opp til 20 bar<br />

P a rt M i c ro n C e n t e r F i l t e r F i l t e r M e d i a C a p a c i t y C a p a c i t y Typical Beta<br />

N u m b e r R a t i n g T h re a d D i a . L e n g t h A re a S o l i d s H 2 O Rating<br />

IN HW 3510 10 1"-12 3.7" / 9.4 cm 5.5" / 14 cm 190 in2 / 1226 cm2 13.68 g 247 ml 10 / 18<br />

IN HW 3510A 10 1 1/8"-16 3.7" / 9.4 cm 5.5" / 14 cm 190 in2 / 1226 cm2 13.68 g 247 ml 10 / 18<br />

IN HW 3525 25 1"-12 3.7" / 9.4 cm 5.5" / 14 cm 190 in2 / 1226 cm2 15.58 g 247 ml 14 / 23<br />

IN HW 3810 10 1"-12 3.7" / 9.4 cm 8" / 20.3 cm 350 in2 / 2258 cm2 25.2 g 455 ml 10 / 18<br />

IN HW 3825 25 1"-12 3.7" / 9.4 cm 8" / 20.3 cm 350 in2 / 2258 cm2 28.7 g 455 ml 14 / 23<br />

IN HW 5710 10 1 1/2"-16 5" / 12.7 cm 7" / 17.8 cm 383 in2 / 2470 cm2 27.58 g 498 ml 10 / 18<br />

IN HW 5725 25 1 1/2"-16 5" / 12.7 cm 7" / 17.8 cm 383 in2 / 2470 cm2 31.40 g 498 ml 14 / 23<br />

IN HW 51110 10 1 1/2"-16 5" / 12.7 cm 11" / 27.9 cm 689 in2 / 4444 cm2 49.61 g 896 ml 10 / 18<br />

IN HW 51125 25 1 1/2"-16 5" / 12.7 cm 11" / 27.9 cm 689 in2 / 4444 cm2 56.50 g 896 ml 14 / 23<br />

IN HW 33RB 10 3/4"-16 3" / 7.6 cm 3" / 7.6 cm 60 in2 / 387 cm 2 4.32 g 78 ml 10 / 18<br />

IN HW 35RB 10 1"-12 3.8" / 9.7 cm 5" / 12.7 cm 190 in2 / 1226 cm2 13.68 g 247 ml 14 / 23<br />

IN HW 57RM 10 1 1/2"-16 5" / 12.7 cm 7" / 17.8 cm 383 in2 / 2470 cm2 27.58 g 498 ml 10 / 18<br />

Maximum operating pressure:100 psi / 1207 kPa.<br />

Silicone Cellulose Media<br />

P a rt M i c ro n C e n t e r F i l t e r F i l t e r M e d i a C a p a c i t y C a p a c i t y Typical Beta<br />

N u m b e r R a t i n g T h re a d D i a . L e n g t h A re a S o l i d s H 2 O Rating<br />

IN HC 3510 10 1"-12 3.7" / 9.4 cm 5.5" / 14 cm 480 in<br />

Micro Glass Media<br />

2 / 3096 cm2 9.04 g N/A 10 / 18<br />

IN HC 3525 25 1"-12 3.7" / 9.4 cm 5.5" / 14 cm 450 in2 / 2903 cm2 12.54 g N/A 25 / 48<br />

IN HC 3810 10 1"-12 3.7" / 9.5 cm 8" / 20.3 cm 878 in2 / 5663 cm2 16.68 g N/A 10 / 18<br />

IN HC 3825 25 1"-12 3.7" / 9.6 cm 9" / 20.3 cm 826 in2 / 5328 cm2 23.13 g N/A 25 / 48<br />

IN HC 5710 10 1 1/2"-16 5" / 12.7 cm 7" / 17.8 cm 950 in2 / 6128 cm2 18.05 g N/A 10 / 18<br />

IN HC 5725 25 1 1/2"-16 5" / 12.7 cm 7" / 17.8 cm 900 in2 / 5805 cm2 25.2 g N/A 25 / 48<br />

IN HC 51110 10 1 1/2"-16 5" / 12.7 cm 11" / 27.9 cm 1710 in2 / 11030 cm2 32.49 g N/A 10 / 18<br />

IN HC 51125 25 1 1/2"-16 5" / 12.7 cm 11" / 27.9 cm 1620 in2 / 10449 cm 2 45.36 g N/A 25 / 48<br />

IN HMG 3606 6 1 1/2"-16 3.75" / 9.5 cm 6" / 15.2 cm 240 in<br />

Stainless Steel Media<br />

2 / 1548 cm2 16.32 g N/A 3 / 6 / 07<br />

IN HM 5710 10 1 1/2"-16 5" / 12.7 cm 7" / 17.8 cm 510 in2 / 3290 cm2 56.1 g N/A 9 / 18 / 19<br />

IN HSSM57 100 1 1/2"-16 5" / 12.7 cm 7" / 17.8 cm 200 in2 / 1290 cm2 N/A N/A 144<br />

IN HSSM511 100 1 1/2"-16 5" / 12.7 cm 11" / 27.9 cm 315 in2 / 2032 cm2 N/A N/A 144<br />

Maximum operating pressure:100 psi / 1207 kPa.<br />

Filtration Specifications<br />

P a rt No. H P 6 0 0 7 7 H P 6 0 0 8 0 H P 6 0 0 8 3 H P 6 0 0 8 6<br />

Flow Rate 20 gpm / 76 lpm 20 gpm / 76 lpm 50 gpm / 189 lpm 50 gpm / 189 lpm<br />

Length Standard Extended Standard Extended<br />

<strong>Pressure</strong> 3000 psi / 210 bar 3000 psi / 207 bar 3000 psi / 207 bar 3000 psi / 207 bar<br />

16

www.mento.no<br />

1.1.2<br />

Mellomtrykksfilter<br />

20 - 120 bar<br />

17

www.mento.no<br />

18

www.mento.no<br />

HMK 05 - DURAMAX<br />

In-Line Medium <strong>Pressure</strong> <strong>Filters</strong><br />

up to 24 bar with spin-on element<br />

Technical Data<br />

• Operating pressure at 2,4 MPa (24 bar).<br />

• Static pressure testing at 5,5 MPa (55 bar).<br />

• By-pass valve setting 170 kPa (1,7 bar)<br />

differential per ISO 3968.<br />

• Available by-pass valve with setting 350 kPa<br />

(3,5 bar) differential.<br />

• Operating temperature -20 +120°C<br />

(-20 +107° C for cellulose).<br />

• Compatibility with hydraulic fluids per ISO 2943.<br />

• Flow rate and pressure drop per ISO 3968<br />

with oil kinematic viscosity 30 cSt at 40°C<br />

and density 0,875 kg/dm 3 .<br />

• Ports threaded per ISO 228/1.<br />

• Tapped predisposition for electrical indicator.<br />

Filter Elements<br />

• Cellulose paper 10 micron.<br />

• Synteq® synthetic media with 5-10-16-22-40 micron.<br />

• Heavy duty steel can with die cast baffle for added<br />

strength and a special head-to-spin-on O-ring seal.<br />

• Element collapse resistance 1,4 MPa (14 bar)<br />

per ISO 2941.<br />

• Spin-on burst resistance 5,5 MPa (55 kPa)<br />

• Element pressure fatigue strength per NFPA T3.10.17<br />

0 - 2,4 MPa (0 - 24 bar) for 100.000 cycles.<br />

• Available intermediate length spin-on L=200 mm.<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

19

www.mento.no<br />

HMK 05 - DURAMAX<br />

In-Line Medium <strong>Pressure</strong> <strong>Filters</strong><br />

up to 24 bar with spin-on element<br />

Specifications<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

20

www.mento.no<br />

HMK 04 - DURAMAX<br />

In-Line Medium <strong>Pressure</strong> <strong>Filters</strong><br />

up to 34 bar with spin-on element<br />

Technical Data<br />

• Operating pressure at 3,45 MPa (34,5 bar).<br />

• Static pressure testing at 6,9 MPa (69 bar).<br />

• By-pass valve setting 170 kPa (1,7 bar)<br />

differential per ISO 3968.<br />

• Available by-pass valve with setting 350 kPa<br />

(3,5 bar) differential.<br />

• Operating temperature -20 +120°C<br />

(-20 +107° C for cellulose).<br />

• Compatibility with hydraulic fluids per ISO 2943.<br />

• Flow rate and pressure drop per ISO 3968<br />

with oil kinematic viscosity 30 cSt at 40°C<br />

and density 0,875 kg/dm 3 .<br />

• Ports threaded per ISO 228/1.<br />

• Tapped predisposition for electrical indicator.<br />

Filter Elements<br />

• Cellulose paper 10 micron.<br />

• Synteq® synthetic media with 5-10-16-22-40 micron.<br />

• Heavy duty steel can with die cast baffle for added<br />

strength and a special head-to-spin-on O-ring seal.<br />

• Element collapse resistance 2 MPa (20 bar)<br />

per ISO 2941.<br />

• Spin-on burst resistance 6,9 MPa (69 bar)<br />

• Element pressure fatigue strength per NFPA T3.10.17<br />

0 - 3,45 MPa (0 - 34,5 bar) for 100.000 cycles.<br />

• Available intermediate length spin-on L=180 mm.<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

21

www.mento.no<br />

Specifications<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

22

www.mento.no<br />

Duplex <strong>Filters</strong><br />

FF2089<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

23

www.mento.no<br />

Duplex Filter<br />

FF2089<br />

Technical data:<br />

Max operating pressure 40 bar<br />

Test pressure 60 bar<br />

Max flow rate 350 l / min (30cSt)<br />

Weight ~65 kg<br />

Housing material EN GJS 450-10 (Cast iron)<br />

Filter element FC1092<br />

Seal material Viton<br />

Safety device to prevent cover opening under pressure<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

Applications:<br />

Diesel fuel oil systems<br />

Heavy fuel oil systems<br />

Propulsion lubricating oil systems<br />

Marine hydraulic systems<br />

24

dp ? (bar) p [bar]<br />

www.mento.no<br />

<strong>Pressure</strong> drop curves for FF2089<br />

Complete Filter: FF2089<br />

Filter Element: FC1092<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

The recommended level of the initial pressure drop for this filter is max 0,5 bar.<br />

If the medium used has a viscosity different from 30cSt, pressure drop over the filter can be<br />

estimated as follows:<br />

dp = (dp30 x viscosity of medium used) / 30 cSt<br />

1,2<br />

1,1<br />

1<br />

0,9<br />

0,8<br />

0,7<br />

0,6<br />

0,5<br />

0,4<br />

0,3<br />

0,2<br />

0,1<br />

FF2089Q020<br />

0<br />

0 100 200 300 400 500 600 700 800<br />

Flow [l/min] viscosity 30 cSt<br />

ONE SIDE BOTH SIDES<br />

Ordering instructions<br />

Table 1 Table 2 Table 3<br />

Table 1<br />

Table 5<br />

VS20<br />

Table 1 Table 2<br />

DEGREE OF FILTRATION<br />

FILTER CONNECTION<br />

Element type CODE<br />

Connection type options CODE<br />

Glass fiber 20 µm Q020<br />

Square flanges * XC56<br />

Glass fiber 10 µm Q010<br />

SAE 2" 3000 Psi DC32<br />

Metal mesh 35 µm M035<br />

* Delivered with blind counter flanges<br />

VS<br />

Indicator: FPC VM<br />

Table 3 Table 4<br />

MAGNET OPTION<br />

INDICATOR BLOCK<br />

Magnet pack option CODE<br />

Indicator block options CODE<br />

With magnet pack M<br />

With indicator block INB<br />

Without magnet pack<br />

Without indicator block<br />

dp ? (bar) p [bar]<br />

1,2<br />

1,1<br />

1<br />

0,9<br />

0,8<br />

0,7<br />

0,6<br />

0,5<br />

0,4<br />

0,3<br />

0,2<br />

0,1<br />

Table 5<br />

dp INDICATOR<br />

Indicator type options CODE<br />

Electric indicator 1,5 bar T15<br />

Visual indicator 1,5 bar V15<br />

Electronic indicator 1,5 bar F15<br />

FF2089M035<br />

0<br />

0 100 200 300 400 500 600 700 800<br />

Flow [l/min] viscosity 30 cSt<br />

ONE SIDE BOTH SIDES<br />

Table 4<br />

25

www.mento.no<br />

26

www.mento.no<br />

Medium <strong>Pressure</strong> <strong>Filters</strong><br />

15/40/80CN <strong>Series</strong><br />

MAX 600 I/min - 70 bar<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

27

www.mento.no<br />

Specification<br />

<strong>Pressure</strong> ratings:<br />

Maximum allowable operating pressure: 70 bar<br />

Rated<br />

fatigue<br />

pressure:<br />

Connections:<br />

56<br />

bar<br />

Several threaded port options available, flange faced ports available<br />

on 80CN.<br />

Connection style Model<br />

15CN 40CN 80CN<br />

BSPF(G) 1”, 3 /4” 11 /4”, 11 /2” 11 /2”, 2”<br />

SAE 12, 16 16, 24 24, 32<br />

ISO 6149 M27 M33 M42, M48<br />

Metric<br />

3000-M<br />

Filter housing:<br />

2”<br />

Head material aluminium.<br />

Bowl material hard anodized aluminium.<br />

Seal material:<br />

Nitrile or fluoroelastomer.<br />

Operating temperature range:<br />

-20°C to +100°C.<br />

Bypass valve & indicator settings:<br />

Table following gives bypass valve and corresponding indicator setting.<br />

Bypass Indicator<br />

1.7 bar 1.2 bar<br />

3.5 bar<br />

Filtration element:<br />

2.5 bar<br />

Degree of filtration:<br />

Determined by Multipass-test according to ISO 16889, see Box 3<br />

in the product configurator.<br />

F<br />

G<br />

Element removal<br />

clearance<br />

65mm (2.50”)<br />

L<br />

H<br />

I<br />

Length 1<br />

A<br />

Length 2<br />

B P<br />

J<br />

25.4 (1.00)<br />

Nominal Hex<br />

E<br />

N<br />

C<br />

K<br />

D<br />

SAE - 4<br />

Drain plug<br />

F<br />

G<br />

L<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

Flow fatigue characteristics:<br />

Filter media is supported so that the optimal fatigue life is achieved<br />

(ISO 3724).<br />

Microglass III (available by request)<br />

Supported with epoxy coated metal wire mesh, end cap material<br />

reinforced composite and metal inner core.<br />

Collapse rating 20 bar (ISO 2941).<br />

Ecoglass III<br />

Supported with plastic net, end cap material reinforced composite.<br />

No metal parts. Collapse rating 10 bar (ISO 2941).<br />

Filter element can only be used together with bowl including Eco-adaptor.<br />

Note: Ecoglass III contributes to ISO 14001 quality.<br />

Indicator options:<br />

- visual M3.<br />

- electrical T1.<br />

- electronic F1(PNP).<br />

- electronic F2(NPN).<br />

For indicator details see catalogue section 6.<br />

Weights (kg):<br />

Model Length 1 Length 2<br />

15CN 1.1 1.6<br />

40CN 2.0 2.5<br />

80CN 5.6 6.9<br />

Fluid compatibility:<br />

Suitable for use with mineral and vegetable oils, and some synthetic<br />

oils. For other fluids, please consult Parker Filtration.<br />

15CN 40CN<br />

80CN<br />

M<br />

Length 1<br />

A<br />

Length 2<br />

B<br />

Element removal<br />

clearance<br />

65mm (2.50”)<br />

M<br />

Dimensions in mm (inch)<br />

Model A B C D E F G H I J K L M* N P<br />

15CN<br />

156.6 250.7 46.5 25.4 71.1 85.9 73.2 82.6 38.1 22.9 42.9 36.6 53 4xM6-1.0x7.9 deep 20-27 Nm<br />

(6.17) (9.87) (1.83) (1.09) (2.80) (3.38) (2.88) (3.25) (1.50) (0.90) (1.69) (1.44)<br />

40CN<br />

170.8 262.4 62.0 32.6 107.2 127.0 111.0 121.9 62.0 31.8 58.8 60.2 53 4xM8-1.25x13 deep 57-68 Nm<br />

(6.73) (10.33) (2.44) (1.28) (4.22) (5.00) (4.37) (4.80) (2.44) (1.25) (2.32) (2.37)<br />

80CN<br />

280.9 401.6 77.7 49.5 124.8 158.7 82.6 151.4 101.6 41.1 79.4 41.3 69 4xM8-1.25x16 deep 80-95 Nm<br />

(11.06) (15.81) (3.06) (1.95) (4.91) (6.25) (3.25) (5.96) (4.00) (1.62) (3.12) (1.63)<br />

Note: add 45mm for T and F indicators<br />

H<br />

J<br />

I<br />

25.4 (1.00)<br />

Nominal Hex<br />

E<br />

K<br />

C<br />

N<br />

P<br />

D<br />

SAE - 4<br />

Drain plug<br />

G<br />

M<br />

L<br />

Length 1<br />

A<br />

Length 2<br />

B<br />

Element removal<br />

clearance<br />

65mm (2.50”)<br />

H<br />

J<br />

I<br />

25.4 (1.00)<br />

Nominal Hex<br />

E<br />

28<br />

N<br />

K<br />

P<br />

C<br />

SAE - 4<br />

Drain plug<br />

F<br />

D

www.mento.no<br />

Ordering Information<br />

Standard products table<br />

Part numbers<br />

15CN110QEVT1KG164<br />

15CN110QEVM3KG164<br />

15CN120QEVT1KG164<br />

15CN120QEVM3KG164<br />

15CN210QEVT1KG164<br />

15CN210QEVM3KG164<br />

15CN220QEVT1KG164<br />

15CN220QEVM3KG164<br />

40CN105QEVT1KG244<br />

40CN105QEVM3KG244<br />

40CN110QEVT1KG244<br />

40CN110QEVM3KG244<br />

40CN120QEVT1KG244<br />

40CN120QEVM3KG244<br />

40CN205QEVT1KG244<br />

40CN205QEVM3KG244<br />

40CN210QEVT1KG244<br />

40CN210QEVM3KG244<br />

40CN220QEVT1KG244<br />

40CN220QEVM3KG244<br />

80CN110QEVT1KG324<br />

80CN110QEVM3KG324<br />

80CN120QEVT1KG324<br />

80CN120QEVM3KG324<br />

80CN210QEVT1KG324<br />

80CN210QEVM3KG324<br />

80CN220QEVT1KG324<br />

80CN220QEVM3KG324<br />

Supercedes<br />

F315CN1R10QETW350C2C219<br />

F315CN1R10QEM250C2C219<br />

F315CN1R20QETW350C2C219<br />

F315CN1R20QEM250C2C219<br />

F315CN2R10QETW350C2C219<br />

F315CN2R10QEM250C2C219<br />

F315CN2R20QETW350C2C219<br />

F315CN2R20QEM250C2C219<br />

F340CN1R05QETW350E2E219<br />

F340CN1R05QEM250E2E219<br />

F340CN1R10QETW350E2E219<br />

F340CN1R10QEM250E2E219<br />

F340CN1R20QETW350E2E219<br />

F340CN1R20QEM250E2E219<br />

F340CN2R05QETW350E2E219<br />

F340CN2R05QEM250E2E219<br />

F340CN2R10QETW350E2E219<br />

F340CN2R10QEM250E2E219<br />

F340CN2R20QETW350E2E219<br />

F340CN2R20QEM250E2E219<br />

F380CN1R10QETW350F2F219<br />

F380CN1R10QEM250F2F219<br />

F380CN1R20QETW350F2F219<br />

F380CN1R20QEM250F2F219<br />

F380CN2R10QETW350F2F219<br />

F380CN2R10QEM250F2F219<br />

F380CN2R20QETW350F2F219<br />

F380CN2R20QEM250F2F219<br />

Flow<br />

(l/min)<br />

50<br />

50<br />

80<br />

80<br />

80<br />

80<br />

100<br />

100<br />

120<br />

120<br />

180<br />

180<br />

260<br />

260<br />

200<br />

200<br />

280<br />

280<br />

320<br />

320<br />

370<br />

370<br />

420<br />

420<br />

530<br />

530<br />

600<br />

600<br />

Model<br />

number<br />

15CN<br />

15CN<br />

15CN<br />

15CN<br />

15CN<br />

15CN<br />

15CN<br />

15CN<br />

40CN<br />

40CN<br />

40CN<br />

40CN<br />

40CN<br />

40CN<br />

40CN<br />

40CN<br />

40CN<br />

40CN<br />

40CN<br />

40CN<br />

80CN<br />

80CN<br />

80CN<br />

80CN<br />

80CN<br />

80CN<br />

80CN<br />

80CN<br />

Element<br />

length<br />

Length 1<br />

Length 1<br />

Length 1<br />

Length 1<br />

Length 2<br />

Length 2<br />

Length 2<br />

Length 2<br />

Length 1<br />

Length 1<br />

Length 1<br />

Length 1<br />

Length 1<br />

Length 1<br />

Length 2<br />

Length 2<br />

Length 2<br />

Length 2<br />

Length 2<br />

Length 2<br />

Length 1<br />

Length 1<br />

Length 1<br />

Length 1<br />

Length 2<br />

Length 2<br />

Length 2<br />

Length 2<br />

Media<br />

rating (µ)<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

Note: Filter assemblies ordered from the product configurator on next page are on extended lead times. Where possible, please make your selection from the table above.<br />

10<br />

10<br />

20<br />

20<br />

10<br />

10<br />

20<br />

20<br />

5<br />

5<br />

10<br />

10<br />

20<br />

20<br />

5<br />

5<br />

10<br />

10<br />

20<br />

20<br />

10<br />

10<br />

20<br />

20<br />

10<br />

10<br />

20<br />

20<br />

Seals<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Fluoroelastomer<br />

Indicator<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Electrical<br />

Visual<br />

Bypass<br />

settings<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

3.5 bar<br />

Ports<br />

G1"<br />

G1"<br />

G1"<br />

G1"<br />

G1"<br />

G1"<br />

G1"<br />

G1"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G1 1 /2"<br />

G2"<br />

G2"<br />

G2"<br />

G2"<br />

G2"<br />

G2"<br />

G2"<br />

G2"<br />

Replacement elements<br />

936700Q<br />

936700Q<br />

936701Q<br />

936701Q<br />

936704Q<br />

936704Q<br />

936705Q<br />

936705Q<br />

936707Q<br />

936707Q<br />

936708Q<br />

936708Q<br />

936709Q<br />

936709Q<br />

936711Q<br />

936711Q<br />

936601Q<br />

936601Q<br />

936712Q<br />

936712Q<br />

936602Q<br />

936602Q<br />

936715Q<br />

936715Q<br />

936718Q<br />

936718Q<br />

936719Q<br />

936719Q<br />

29

www.mento.no<br />

Ordering Information (cont.)<br />

Product Configurator<br />

Box 1 Box 2<br />

40CN 2<br />

Box 1<br />

Code<br />

Model<br />

Small size MP filter, T-port<br />

Medium size MP filter, T-port<br />

Large size MP filter, T-port<br />

Box 3<br />

Element media<br />

Ecoglass III element<br />

Box 5<br />

No indicator port<br />

Visual indicator<br />

Electrical indicator<br />

Plugged with steel plug<br />

Electronic 4 LED, PNP, N.O.<br />

Electronic 4 LED, NPN, N.O.<br />

Electronic 4 LED, PNP, N.C.<br />

Electronic 4 LED, NPN, N.C.<br />

Box 8<br />

Options<br />

Options<br />

Standard drain port on bowl<br />

Indicator<br />

Box 3<br />

10QE<br />

Code<br />

4<br />

Code<br />

15CN<br />

40CN<br />

80CN<br />

Code<br />

N<br />

M3<br />

T1<br />

P<br />

F1<br />

F2<br />

F3<br />

F4<br />

Box 4<br />

V<br />

Box 2<br />

Length<br />

Length 1<br />

Length 2<br />

Note: When using Ecoglass III elements a bowl with reusable Eco-adaptor is required.<br />

Filter assemblies with Microglass III elements are available by request<br />

Box 6<br />

Ecoglass III elements (Fluoroelastomer seals)<br />

Model<br />

15CN-1<br />

15CN-2<br />

40CN-1<br />

40CN-2<br />

80CN-1<br />

80CN-2<br />

936758<br />

936759<br />

936760<br />

936761<br />

936763<br />

936764<br />

ßx(c)=2<br />

50.0%<br />

N/A<br />

N/A<br />

N/A<br />

6<br />

02QE<br />

936698Q<br />

936702Q<br />

936706Q<br />

936710Q<br />

936713Q<br />

936716Q<br />

Degree of filtration<br />

Glass fibre<br />

2µ media<br />

02QE<br />

05QE<br />

936699Q<br />

936703Q<br />

936707Q<br />

936711Q<br />

936714Q<br />

936717Q<br />

Conversion bowl assembly<br />

(to retrofit existing CN filter housings to use coreless elements)<br />

10QE<br />

936700Q<br />

936704Q<br />

936708Q<br />

936601Q<br />

936602Q<br />

936718Q<br />

15CN-1 coreless element bowl assembly<br />

15CN-2 coreless element bowl assembly<br />

40CN-1 coreless element bowl assembly<br />

40CN-2 coreless element bowl assembly<br />

80CN-1 coreless element bowl assembly<br />

80CN-2 coreless element bowl assembly<br />

5µ media<br />

05QE<br />

Please note the bolded options reflect standard options with a reduced lead-time<br />

of (4) weeks or less. Consult Parker Filtration on all other lead-time options.<br />

Box 5<br />

M3<br />

Filter type<br />

Code<br />

1<br />

2<br />

Bypass valve<br />

1.7 bar<br />

3.5 bar<br />

20QE<br />

936701Q<br />

936705Q<br />

936709Q<br />

936712Q<br />

936715Q<br />

936719Q<br />

10µ media<br />

10QE<br />

20µ media<br />

20QE<br />

1.0 Væskefiltrering<br />

1.1.2 Mellomtrykksfilter 20 - 120 bar<br />

Box 6<br />

K<br />

Bypass valve<br />

Indicator<br />

1.2 bar<br />

2.5 bar<br />

Model<br />

15CN<br />

40CN<br />

80CN<br />

Code<br />

G<br />

K<br />

When filter includes a bypass valve but not an indicator,<br />

code denotes bypass setting.<br />

Degree of filtration<br />

Average filtration beta ratio ß (ISO 16889) / particle size µm [c]<br />

ßx(c)=10 ßx(c)=75 ßx(c)=100 ßx(c)=200 ßx(c)=1000<br />

% efficiency, based on the above beta ratio (ßx)<br />

90.0% 98.7% 99.0% 95.5% 99.8%<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

4.5<br />

N/A<br />

4.5<br />

5<br />

6<br />

7<br />

6<br />

8.5<br />

9<br />

10<br />

12<br />

11<br />

17<br />

18<br />

20<br />

22<br />

Seal kits<br />

Nitrile<br />

S02594<br />

S02596<br />

S03543<br />

123<br />

123<br />

123<br />

123<br />

Box 7<br />

G24<br />

Replacement element part numbers for conventional assemblies<br />

Elements with nitrile seals Elements with Fluoroelastomer seals<br />

Model 02Q 05Q 10Q 20Q Model 02Q 05Q 10Q 20Q<br />

15CN-1 928935Q G04041Q 928934Q 930367Q 15CN-1 932610Q G04189Q 932612Q 930369Q<br />

15CN-2 928953Q G04169Q 928952Q 930368Q 15CN-2 932616Q G04190Q 932618Q 930370Q<br />

40CN-1 926696Q G04048Q 926835Q 930099Q 40CN-1 926716Q G04191Q 926836Q 930100Q<br />

40CN-2 926697Q G04167Q 926837Q 930118Q 40CN-2 926717Q G04192Q 926838Q 930119Q<br />

80CN-1 932656Q 932657Q 932658Q 929899Q 80CN-1 932659Q 932660Q 832661Q 929903Q<br />

80CN-2 932662Q 932663Q 932664Q 929923Q 80CN-2 932665Q 932666Q 932667Q 929927Q<br />

Code<br />

Metal free<br />

Ecoglass III<br />

02QE<br />

05QE<br />

10QE<br />

20QE<br />

Housing, port size<br />

15CN-1, G1<br />

15CN-2, G1<br />

40CN-1, G1 1 /2<br />

40CN-2, G1 1 /2<br />

80CN-1, G2<br />

80CN-2, G2<br />

Box 8<br />

4<br />

<strong>High</strong>lights Key (Denotes part number availability)<br />

Item is standard<br />

Item is standard with “green” options<br />

Item is semi standard<br />

Item is non standard<br />

Box 4<br />

Seal type<br />

Seal material<br />

Fluoroelastomer<br />

Nitrile<br />

02QE<br />

10<br />

30<br />

60<br />

80<br />

150<br />

180<br />

Code<br />

V<br />

B<br />

Ports<br />

15CN:Thread G3 /4<br />

Thread G1<br />

Thread SAE 12<br />

Thread SAE 16<br />

Thread M27, ISO6149<br />

40CN:Thread G11 /4<br />

Thread G11 /2<br />

Thread SAE 16<br />

Thread SAE 24<br />

Thread M33, ISO6149<br />

80CN:Thread G11 Box 7<br />

Filter connection<br />

/2<br />

Thread G2<br />

Thread SAE 24<br />

Thread SAE 32<br />

Thread M42, ISO6149<br />

Thread M48, ISO6149<br />

SAE flange 2" 3000-M<br />

Fluoroelastomer*<br />

S02595<br />

S02597<br />

S03544<br />

05QE<br />

30<br />

70<br />

120<br />

200<br />

300<br />

420<br />

10QE<br />

50<br />

80<br />

180<br />

280<br />

370<br />

530<br />

30<br />

Note: Standard items are in stock, semi standard items are available within four weeks<br />

Code<br />

G12<br />

G16<br />

S12<br />

S16<br />

M27<br />

G20<br />

G24<br />

S16<br />

S24<br />

M33<br />

G24<br />

G32<br />

S24<br />

S32<br />

M42<br />

M48<br />

R32<br />

Nominal flow (l/min) for filter assembly at viscosity 30cSt<br />

20QE<br />

80<br />

100<br />

260<br />

320<br />

420<br />

600<br />

* Fluoroelastomers are available under various registered trademarks,<br />

including Viton (a registered trademark of DuPont) and Fluorel (a registered<br />

trademark of 3M)

www.mento.no<br />

FMK - FM<br />

In-Line Medium <strong>Pressure</strong> <strong>Filters</strong><br />

up to 120 bar with take apart<br />

Technical Data<br />

• Filter head in tempered aluminum.<br />

• Aluminum bowl.<br />

• Max. operating pressure at 12 MPa (120 bar),<br />

static pressure testing at 18 MPa (180 bar).<br />