ADCA-Flash condensing FCD

ADCA-Flash condensing FCD

ADCA-Flash condensing FCD

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

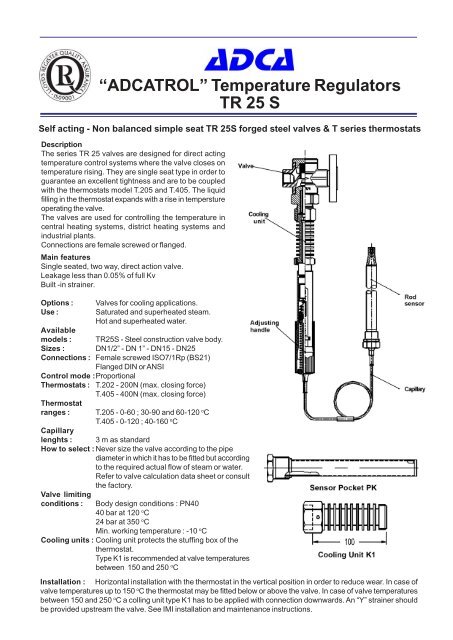

“<strong>ADCA</strong>TROL” Temperature Regulators<br />

TR 25 S<br />

Self acting - Non balanced simple seat TR 25S forged steel valves & T series thermostats<br />

Description<br />

The series TR 25 valves are designed for direct acting<br />

temperature control systems where the valve closes on<br />

temperature rising. They are single seat type in order to<br />

guarantee an excellent tightness and are to be coupled<br />

with the thermostats model T.205 and T.405. The liquid<br />

filling in the thermostat expands with a rise in tempersture<br />

operating the valve.<br />

The valves are used for controlling the temperature in<br />

central heating systems, district heating systems and<br />

industrial plants.<br />

Connections are female screwed or flanged.<br />

Main features<br />

Single seated, two way, direct action valve.<br />

Leakage less than 0.05% of full Kv<br />

Built -in strainer.<br />

Options :<br />

Use :<br />

Valves for cooling applications.<br />

Saturated and superheated steam.<br />

Hot and superheated water.<br />

Available<br />

models : TR25S - Steel construction valve body.<br />

Sizes : DN1/2” - DN 1” - DN15 - DN25<br />

Connections : Female screwed ISO7/1Rp (BS21)<br />

Flanged DIN or ANSI<br />

Control mode :Proportional<br />

Thermostats :<br />

Thermostat<br />

ranges :<br />

T.202 - 200N (max. closing force)<br />

T.405 - 400N (max. closing force)<br />

T.205 - 0-60 ; 30-90 and 60-120 o C<br />

T.405 - 0-120 ; 40-160 o C<br />

Capillary<br />

lenghts : 3 m as standard<br />

How to select : Never size the valve according to the pipe<br />

diameter in which it has to be fitted but according<br />

to the required actual flow of steam or water.<br />

Refer to valve calculation data sheet or consult<br />

the factory.<br />

Valve limiting<br />

conditions :<br />

Body design conditions : PN40<br />

40 bar at 120 o C<br />

24 bar at 350 o C<br />

Min. working temperature : -10 o C<br />

Cooling units : Cooling unit protects the stuffing box of the<br />

thermostat.<br />

Type K1 is recommended at valve temperatures<br />

between 150 and 250 o C<br />

Installation : Horizontal installation with the thermostat in the vertical position in order to reduce wear. In case of<br />

valve temperatures up to 150 o C the thermostat may be fitted below or above the valve. In case of valve temperatures<br />

between 150 and 250 o C a colling unit type K1 has to be applied with connection downwards. An “Y” strainer should<br />

be provided upstream the valve. See IMI installation and maintenance instructions.

Dimensions (mm)<br />

Type A B C E Kg<br />

T.205 305 405 210 22 1.8<br />

T.405 385 525 390 22 2.6<br />

Specifications<br />

Type Connection Opening DN Kvs value Valve Stroke<br />

DN in mm m3/h mm<br />

TR25-15/4 15 4 0.20 6<br />

TR25-15/6 15 6 0.45 6<br />

TR25-15/9 15 9 0.95 6<br />

TR25-15/12 15 12 1.70 6<br />

TR25-15 15 15 2.75 6<br />

TR25-20/9 20 9 0.95 6.5<br />

TR25-20/15 20 15 2.75 6.5<br />

TR25-20/20 20 20 5 6.5<br />

TR25-25/20 25 20 5 7<br />

Max. Permissible Diff.pressure<br />

with T 205 thermostat :<br />

21 bar for valve DN15 with 4 & 6 mm seat diam.<br />

13 bar for valve DN15 with 9 mm seat diam.<br />

9.3 bar for valve DN15 with 12 mm seat diam.<br />

5.3 bar for valve DN15<br />

5.3 bar for valve DN20 with 15 mm seat diam.<br />

2.9 bar for valve DN20 with 20 mm seat diam.<br />

2.9 bar for valve DN25 with 20 mm seat diam.<br />

With T.405 thermostat :<br />

40 bar for valve DN15 with 4 & 6 mm seat diam.<br />

38 bar for valve DN15 with 9 mm seat diam.<br />

24 bar for valve DN15 with 12 mm seat diam.<br />

15 bar for valve DN15<br />

15 bar for valve DN20 with 15 mm seat diam.<br />

9 bar for valve DN20 with 20 mm seat diam.<br />

9 bar for valve DN25 with 20 mm seat diam.<br />

Valve Dimensions (mm)<br />

Screwed ends DIN Flanges<br />

DN A B C F Kg D E Kg<br />

1/2” 90 40 70 50 1.2 130 47.5 2.6<br />

3/4” 90 40 70 50 1.2 150 52.5 3.2<br />

3/4”* 100 45 75 55 1.6 150 52.5 3.6<br />

1” 100 45 75 55 1.6 160 57.5 4.2<br />

* Only model TR25-20/20<br />

Materials (TR25)<br />

Pos. Designation Material<br />

1 Body C 22.8<br />

2 Bonnet AISI 304<br />

3* Gasket St.st. / Graphite<br />

4* Valve AISI 316<br />

5 Seat AISI 316<br />

6* Spring AISI 302<br />

7 Cap A 105<br />

8* Strainer screen AISI 304<br />

9* Cap gasket St. st. / Graphite<br />

* Available spare parts<br />

Proportional band<br />

The proportional band is the temperature change required for the valve to move from fully open to fully closed. It<br />

depends on the valve stroke and on the thermostat movement per o C, and is calculated as follows.<br />

Proportional Band = Valve stroke (mm)<br />

Thermostat mov. (mm/ o C)<br />

Thermostat movement in mm per o C<br />

A proportional band in the range 8-13 o C is suitable for most applications. A smaller proportional band is not ideal where<br />

heat load varies rapidly.