FRLs and Accessories Catalog - Numatics Incorporated

FRLs and Accessories Catalog - Numatics Incorporated

FRLs and Accessories Catalog - Numatics Incorporated

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

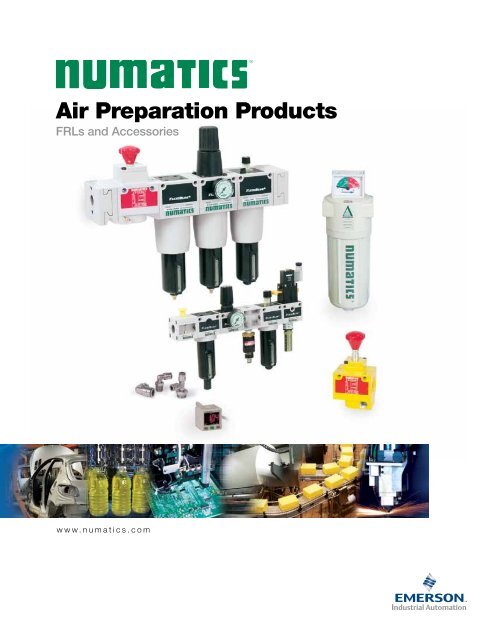

Air Preparation Products<strong>FRLs</strong> <strong>and</strong> <strong>Accessories</strong>www.numatics.com

<strong>Numatics</strong>, Inc. is a leading manufacturer of pneumatic products <strong>and</strong> motion controlproducts. Our broad spectrum of st<strong>and</strong>ard, custom-developed products <strong>and</strong> application componentshave made a significant impact on pneumatic innovation as well as pneumatic <strong>and</strong> motion controltechnology. Our company has an extensive history of generating innovative concepts <strong>and</strong> technologicalbreakthroughs. Many of today’s st<strong>and</strong>ard features in pneumatic technology were industry firsts from<strong>Numatics</strong>. We continue our innovative approach to product development by developing electric motioncontrol solutions <strong>and</strong> enhancing our embedded Fieldbus <strong>and</strong> I/O products to continually meet <strong>and</strong> solveour customer’s application requirements.Today <strong>Numatics</strong> is proud tobe a part of the IndustrialAutomation Division ofEmerson Electric Co.Emerson (NYSE:EMR), basedin St. Louis, Missouri (USA),is a global leader in bringingtechnology <strong>and</strong> engineeringtogether to provide innovativesolutions for customers inindustrial, commercial, <strong>and</strong>consumer markets throughits network power, processmanagement, industrialautomation, climate technologies,<strong>and</strong> appliance <strong>and</strong> toolsbusinesses. For more information,visit www.Emerson.com.i

<strong>Numatics</strong> Express 2Day <strong>and</strong> 3Day ShippingProgram guarantees † product shipment in two orthree business days. Unlike most traditional quick ship programs, the <strong>Numatics</strong> Express Shipping Program includes themost comprehensive offering in the industry. This program encompasses the range <strong>and</strong> options that you require!<strong>Numatics</strong> is committed to offering you the highest level of customer service, quality <strong>and</strong> performance.<strong>Numatics</strong> Express 2Day shipping program guarantees † productshipment in two business days. The program includes the mostpopular configurations of the 2000, Mark <strong>and</strong> L Series valves, includingindividual bases, manifold blocks, s<strong>and</strong>wich regulators, particulatefilters, coalescing filters, regulators, lubricators, filter-regulators,solenoid soft start quick exhaust valves, shut-off valves, <strong>and</strong> diverterblocks. Additionally, A Series N.F.P.A. Interchange cylinders, M SeriesRound Body Interchangeable air cylinders, SH Series Linear Slides,<strong>and</strong> applicable switches <strong>and</strong> mounting accessories are offered in the<strong>Numatics</strong> 2Day shipping program.<strong>Numatics</strong> guarantees † to ship any order received before 3 pm EST forup to 10 of the valve assemblies, <strong>and</strong> air preparation components,cylinders configured from this catalog in two business days. Saturdays,Sundays, <strong>and</strong> Holidays are excluded. <strong>Numatics</strong> Express orders cannotbe cancelled or adjusted once entered.In addition the <strong>Numatics</strong> Express shipping program offers a 3Dayshipping program that guarantees † product shipment of a fully assembled<strong>and</strong> tested valve manifold in 3 business days. The programincludes the most popular manifold configurations of the 2000 <strong>and</strong>Mark series valves: Sub D, Terminal Strip <strong>and</strong> Device Net Electronic Options Can be configured for DIN Rail Mounting <strong>and</strong> Muffled Exhaust Shipped complete <strong>and</strong> 100% testedThe 3Day Express shipping program enables you to create a 2 to 8station manifold assembly complete with any combination of valves,regulators, <strong>and</strong> blank stations that can be configured from the valvemodel charts in this catalog.<strong>Numatics</strong> guarantees † to ship any order received before 3 pm EST forup to 5 manifold assemblies configured from this catalog in three businessdays or <strong>Numatics</strong> pays the shipping cost. Saturdays, Sundays,<strong>and</strong> Holidays are excluded. <strong>Numatics</strong> Express orders cannot becancelled or adjusted once entered.We are committed to providing you with an unmatched level of customer service, quality, <strong>and</strong> reliability.If you cannot locate the specific product for your application or need additional product specifications, visitwww.numatics.com or call 888-686-2842.ii†As industry requirements change, <strong>Numatics</strong> reserves the right to modify the contents of this catalog <strong>and</strong> program without notification. Updates on this programcan be obtained from the <strong>Numatics</strong> website www.numatics.com or by calling 888-686-2842, or by contacting your local <strong>Numatics</strong> representative or distributor<strong>and</strong> referencing the <strong>Numatics</strong> Express program.

Welcome to the World of Fluid Automation...Since 1945, <strong>Numatics</strong> has emerged as the prominent specialist in developing <strong>and</strong> manufacturing pneumatic<strong>and</strong> fluid power components for a widely diverse field of automated industry. From idea to implementation,leading engineers choose <strong>Numatics</strong> as their single source for: <strong>and</strong> service from around the worldNumasizingDeveloped by <strong>Numatics</strong>, Numasizing offers a whole new levelof fluid power system optimization. Compare large amounts ofcomponent <strong>and</strong> process data against user objectives <strong>and</strong> industrybenchmarks for the best possible size, pneumatic pressure,actuator stroke velocities <strong>and</strong> other part <strong>and</strong> process variabledeterminations.CAD ModelingSave critical developmenttime with the most innovative CAD configurationprogram in the pneumatic component industry.<strong>Numatics</strong> in 3D eliminates the timeconsuming process associated withdesigning components from scratchbased on information found inconventional paper catalogs.The models are available in 85different native CAD formats in2D drawings <strong>and</strong> 3D models, including all the popularformats including Catia, I-DEAS, Pro/Engineer,SolidWorks, Unigraphics <strong>and</strong> more.iii

Table of ContentsFlexiBlok FRL Series*Introduction to FlexiBlok 1-8Particulate Filters 9Coalescing Filters 10Regulators 11-14Particulate Filter-Regulators 15Coalescing Filter-Regulators 16Lubricators 17 Diverter Blocks <strong>and</strong> End Plates 23Bowl Drain Options 24FlexiBlok FRL Assemblies (StockBlok <strong>and</strong> ModuBlok) 25-30*Port sizes: 14 Series (1/8 & 1/4), 22 Series (1/4, 3/8, & 1/2) 32 Series (1/2 & 3/4), 42 Series (3/4 & 1)Miniature FRL ComponentsPort Sizes: 12 Series (1/8 & 1/4) 31-40High Flow FRL ComponentsPort Sizes: 50 Series FRL (1/4 to 1 1/2) 50 Series Pilot Regulators (1/4 to 2 1/2) 41-48Stainless Steel <strong>FRLs</strong>Port Sizes: 70 & 72 Series (1/4 & 1/2) 49-60Precision RegulatorsR80, R82, R88, R83, R84, R85, R87, R89 61-76Lockout Valves High Flow Premium FiltersDrip LegsPort Sizes: Delta 901 Series Particulate, Coalescing & Water Separators (1/4 to 3) 87-100Port Sizes: ADL Series (1/4 to 2) 101-102Digital Pressure/Vacuum Sensors280 Series 103-107Gauges 108Additional <strong>Accessories</strong> 109-145

Introduction to <strong>Numatics</strong>!"#$%&"'( ®FRLSERIESThe !"#$%&"'( ® AdvantageWhile most competitors require numerous additionalparts to assemble FRL components, the <strong>Numatics</strong>!"#$%&"'( ®FRL products are easily assembled with2 button head screws <strong>and</strong> an o-ring seal. This modulartype design reduces the potential for leakage duringassembly <strong>and</strong> lowers the overall cost since brackets orextra tools are not required.Air PrepThe !"#$%&"'( ®line is designed to be simple <strong>and</strong> economical... Service can be performed while the component is installed in the air line.Flexiblok: FRL Series 22, 32 <strong>and</strong> 42 Series bowls feature a unique locking tab bowl. Just pull the locking tab down, turn thebowl 45º, <strong>and</strong> pull down to remove. The unique design of the 22, 32 <strong>and</strong> 42 series bowls allows the o-ring to be held captive on the bowl,making it easy to check <strong>and</strong> replace if necessary. Differential pressure indicators are st<strong>and</strong>ard on all 22, 32 <strong>and</strong> 42 Series coalescers. Particulate filters feature a st<strong>and</strong>ard 5 micron element (optional 40 micron element). Coalescing filters feature dual support cores which prevent rupture <strong>and</strong> collapse. CircleVision bowls allow the machine operator or manager a clear visual indication of the liquid level in afilter or lubricator bowl from up to 40 feet away. Every product is tested <strong>and</strong> approved for quality assurance.!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&41

!"#$%&"'( ®FRLSERIESIntroduction to <strong>Numatics</strong>Air PrepThe !"#$%&"'( ® AdvantageDesigned with lightweight but sturdy aluminum castings, the !"#$%&"'( ®FRL Series offers themost reliable performance <strong>and</strong> durability of any FRL line. Most components can be modified withreadily available options <strong>and</strong> accessories, such as metal bowls <strong>and</strong> easy-to-operate drains.The following is an example of an Flexiblok ®FRL assembly <strong>and</strong> a description of each component.For additional specifications <strong>and</strong> product selection charts, please refer to pages 9 to 29.1Shutoff Valve3Flexiblok: FRL SeriesManual shutoff used to relieve downstream pressurefor servicing or maintenance. Security hole provided forlockout capabilities. May also be used as a st<strong>and</strong>-aloneunit.2FilterParticulate Filter: 5 micron filtration (shown) used as aprimary filter to remove water, dust, <strong>and</strong> debris from air line(40 micron optional). Water removal efficiency is greaterthan 90% at rated flow.Coalescing Filter: used as a secondary filter to removeup to 99.99% of oil <strong>and</strong> particles. Available with fourdifferent type elements - 0.01, .3, <strong>and</strong> .7 micron filtration<strong>and</strong> a vapor adsorbing element that utilizes activatedcarbon to deodorize compressed air. Recommended uses:C grade element, identified by its blue drain layer, is a coarse filter for largeamounts of water, rust, pipe scale, <strong>and</strong> liquid hydrocarbons. Excellent forenvironments that have severe contamination. Can be used for lubricated or ‘dry’systems. Ideal for mainline filtration of plant air.D grade element, identified by its green drain layer, is a fine filter for cylinder orvalves - especially when the circuit is being run without lubrication (‘dry’). Excellentfilter for desiccant or regenerative style dryers.E grade element, identified by its red drain layer, is an ultra fine filter for oil-freeinstrumentation air, blow molding, food <strong>and</strong> drug packaging, electronics applications,<strong>and</strong> other applications requiring maximum contamination removal.F grade element, identified by its white drain layer, is an adsorbing filter that utilizesactivated carbon to capture hydrocarbon vapor <strong>and</strong> deodorize compressed air.Typically it is used to protect worker environments, food <strong>and</strong> drug applications,breathing air, <strong>and</strong> instrumentation for analytical instruments. Life expectancy isapproximately 3 months at rated flow.123RegulatorReduces supply pressure to a required working pressure.Available in relieving or non-relieving styles <strong>and</strong> in fourdifferent pressure ratings.4Diverter Block9Provides total versatility; mounts directly inline to allowadditional components to be manifolded without excessivepressure drop.2!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Introduction to <strong>Numatics</strong>!"#$%&"'( ®FRLSERIESThe !"#$%&"'( ® Advantage5LubricatorDesigned to meter oil aerosols into the air stream wherelubrication is required. Tamper-resistant adjustment knobeliminates unauthorized adjustments.Air Prep6Solenoid Soft Start QuickExhaust Valve75When solenoid air pilot is energized, adjustable flowcontrol allows system to be pressurized slowly. Whendownstream pressure reaches approximately 60% ofupstream pressure, slow start shifts to full flow condition.When solenoid air pilot is de-energized, downstreampressure exhausts to atmosphere. Equipped with manualoverride <strong>and</strong> lockout.7Pressure SwitchAllows for remote monitoring of system pressure. Anadjustable, tamper-resistant knob resists unauthorizedchanges.Flexiblok: FRL Series468BowlsThree types available: polycarbonate bowl with guard(st<strong>and</strong>ard), metal bowl with sight glass, <strong>and</strong> CircleVision- a metal bowl wrapped in polycarbonate, allowing a 360ºview of liquid level in bowl.9DrainsSix types available: Manual drain with internal barb fitting(1/4" I.D.) for drain tube (st<strong>and</strong>ard), automatic float drain,flexible drain, external pulse drain, metal manual drain,<strong>and</strong> manual lever drain. All feature unique characteristicssuitable for many different applications.High FlowThe <strong>Numatics</strong> FRL !"#$%&"'( ®line is designed for highflows - with minimal pressure drop.8Product ConnectionEach !"#$%&"'( ®component is engineered to connectdirectly to the next without inserts or special tools,ensuring optimum stability <strong>and</strong> strength.Integral Mounting Holes!"#$%&"'( ®components mount directly without theuse of special brackets or inserts, allowing for individualcomponent mounting for st<strong>and</strong>-alone units.!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&43

!"#$%&"'( ®FRLSERIESIntroduction to <strong>Numatics</strong>Air PrepThe !"#$%&"'( ® Advantage<strong>Numatics</strong> coalescing filters use a borosilicate glass fiberto remove contaminant from air lines. Air flows from theinside to the outside of the element through progressivelylarger openings in the media, trapping contaminantparticles <strong>and</strong> forcing liquids to form into larger drops <strong>and</strong>drain to the bottom of the bowl. <strong>Numatics</strong> filters are usedto remove hydrocarbon, oil, <strong>and</strong> more. The filters aremade up of seven main features:31End Seals5Flexiblok: FRL SeriesUrethane end seals provide positive seal. Compatible withmineral base <strong>and</strong> synthetic lubricants (silicone is optional)2Optional Pleated Prefilter3 micron media protects the fine borosilicate fibers, extendingthe life of the coalescing media.3Inner Media Wrap - Inner Support Core26Allows cross flow of gas which initiates the coalescing process.Helps protect element from damage due to excessive pressuredrop4MediaFour media choices for best performance. Proprietary glassfiber blend combines low differential pressures <strong>and</strong> highefficiencies with maximum holding capacity.5Outer Media Wrap - Outer Support CoreProvides structural stability to filter media from excessivepressure drop6Drain LayerNon-wicking fiber prevents re-entrainment47Color-coded WebbingAllows for easy identification of media typeSee next page for more information about our line ofcoalescing filters, including media grade information,application notes, <strong>and</strong> a helpful chart showing diametersof particles <strong>and</strong> aerosols in microns.71Cross-section of <strong>Numatics</strong> coalescing filterelement, with optional pleated prefilter4!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Introduction to <strong>Numatics</strong>!"#$%&"'( ®FRLSERIESThe !"#$%&"'( ® AdvantageAir flows from the inside to the outside of the elementthrough progressively larger openings in the media. Ascontamination moves through the element, solid particlesare trapped <strong>and</strong> liquids are formed into large droplets. Asthe air exits the element, surface tension holds the liquids<strong>and</strong> allows them to drain to the bottom.Air PrepThe <strong>Numatics</strong> 0.3 micron borosilicate glass fiberelement, when magnified 228x (left), showsdeep, tortuous paths <strong>and</strong> large air pockets whichprovide high performance contaminate removal<strong>and</strong> longer life.Contamination removal from a typicalcompressed air line with 0.3 micron <strong>Numatics</strong>media is shown magnified 40x (right). TheScanning electronmicrograph (at 228x)Dirty filtermagnification (at 40x)contamination contains hydrocarbon (black), oil (opaque drops), <strong>and</strong> metal fragments (shiny spots).Flexiblok: FRL SeriesWith <strong>Numatics</strong> elements like the one on the left installed in your system, the contamination on the right won’t get towhere it can cause damage. Your system lasts longer <strong>and</strong> costs less.What you get is not always what you seeMicrons:0.001 0.012 4 6 8 2 4 6 80.12 4 6 812 4 6 8102 4 6 8100 1000 100002 4 6 8 2 4 6 8Resin DustOil AerosolTobacco SmokeMetallurgical Dust, FumesFly AshCoal DustFertilizer, Ground LimestoneSoot Sulfur Fumes Cement DustZinc Oxide Fumes Insecticide Powder Insecticide PowderSea Salt CrystalsPaint PigmentsPowdered MilkPneumatic JetDropletsPollenFlourAtmosphere DustVirusesBacteriaSmog Cloud <strong>and</strong> Fog Drizzle <strong>and</strong> Rainmicroscope 10x magnifier human visibility!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&45

!"#$%&"'( ®FRLSERIESIntroduction to <strong>Numatics</strong>Air PrepEndless Manifold PossibilitiesThe !"#$%&"'( ®14 Series Manifold Regulator allowsseveral regulators to be connected together in a line. Sucha combination may be manifolded left to right or, using a 14Series Diverter Block, up <strong>and</strong> down, providing an option for anymounting scenario.Flexiblok: FRL Series<strong>Numatics</strong> In-Fittings are the perfect solution for connecting tubingfrom a Manifold Regulator to the application. For more informationsee the ‘In-Fittings’ section in this catalog.The Manifold Regulator allows flexibility with any necessarypressure. The common P1 port through each regulator makes itpossible for the 2nd, 3rd, <strong>and</strong> any other following inline regulatorto provide independent pressure. For example, when 100 PSIenters the first manifold regulator, that pressure will continue tobe carried across all following regulators, giving each regulator inthe line 100 PSI primary pressure. The reduced pressure is takenfrom the gauge ports, either front or back!A system equipped with the Manifold Regulator can help reduceoperation costs, since several applications can use pressuresupplied by a single FRL assembly.No room to build left to right?Regulators can be manifolded verticallyusing 14 Series Diverter Blocks.Vertical not an option? Manifold regulatorsare flexible enough to be built in anydirection (notice use of a st<strong>and</strong>ard regulatordownstream of manifold regulators forreduced & stabilized pressure exiting thelubricator)!6!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Introduction to <strong>Numatics</strong>!"#$%&"'( ®FRLSERIESEndless Manifold PossibilitiesAir PrepThe <strong>Numatics</strong> !"#$%&"'( ®FRL line leads the industry in ease of assembly. While manycompetitors rely on special brackets, mounting kits, port connectors, <strong>and</strong> componentconnectors for assembly - which are not only costly but are awkward <strong>and</strong> difficult to use -!"#$%&"'( ®components use only a single o-ring <strong>and</strong> two screws to connect together.Integrated mounting holes eliminate the need for mounting brackets. The need for endplates is eliminated, as the in/out ports of all components are tapped so that any unit canbe used as a st<strong>and</strong> alone unit.Flexiblok: FRL SeriesBy eliminating the need for additional special components, the <strong>Numatics</strong> !"#$%&"'( ®line keeps costs down <strong>and</strong> maintenance <strong>and</strong> assembly quick <strong>and</strong> easy.Less is More with !"#$%&"'( ®The typical !"#$%&"'( ®FRL assembly (filter/regulator/lubricator) uses a total of 9 pieces toconnect the three components. Some competitor assemblies require as many as 29 individualpieces. Most of these necessary parts are built into !"#$%&"'( ®components.!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&47

!"#$%&"'( ®FRLSERIESIntroduction to <strong>Numatics</strong>Air PrepFlexiblok: FRL Series<strong>Numatics</strong> gained its worldwide reputation in the air valve industry with the invention of the multi-purpose precision lapped spool <strong>and</strong>sleeve assembly design. To complement our valve line <strong>and</strong> air logic systems, <strong>Numatics</strong> began exp<strong>and</strong>ing its product line to include<strong>FRLs</strong> <strong>and</strong> numerous air preparation products in 1988. Today, <strong>Numatics</strong> leads the industry in air preparation equipment. Here’s how<strong>Numatics</strong> can provide for all of your air preparation needs:1 <strong>Numatics</strong> Automatic Drain ValveAutomatically expels water on timed sequence, eliminating the potentialfor water carryover.2 Air Header <strong>and</strong> Air DropShould be installed in a closed loop around plant with a 1/4” per 10’slope to allow water to drain. Remove air from top of header to preventmoisture or contaminant from continuing toward application.3 Drip LegUsually sized three times the diameter of the air drop. Collects moisture<strong>and</strong> contaminant.4 <strong>Numatics</strong> ValvesPerforms equally well with or without lubrication. The lapped spool <strong>and</strong>sleeve valve is the most reliable valve for dirty or clean environments.For maximum performance, filtration is recommended.5 <strong>Numatics</strong> CylindersPerforms equally well with or without lubrication. New seal designeliminates packing cylinder bore with grease to achieve non-lubefunction.6 <strong>Numatics</strong> Lockout ValvesAllows system air to be exhausted quickly for safety or othermaintenance functions. Large locking hole for trade locked or othersecurity device prevents system from being accidentally turned onduring maintenance. Meets OSHA specifications.7 Electropneumatic TransducersI-P/E-P Pressure Transducer uses critical orifices <strong>and</strong> components thatmay be damaged by oils or carryovers incompatible with circuitry.8 <strong>Numatics</strong> !"#$%&"'( ®Shut Off ValvesRelieving model allows bleed down of downstream air for maintenancefunctions. Can be locked out for security. Meets OSHA specifications.9<strong>Numatics</strong> !"#$%&"'( ®Particulate FiltersDesigned to remove accumulated condensation <strong>and</strong> particles.Recommended st<strong>and</strong>ard filtration is 5 micron (40 micron optional). Alsoavailable as a coalescing filter. Optional automatic drain dispels liquidfrom bowl.10 <strong>Numatics</strong> !"#$%&"'( ®RegulatorReduces system pressure to working pressure saving both compressedair costs <strong>and</strong> pressure fluctuation. Since increasing pressure does notnecessarily increase speed, the lowest pressure required to perform thetask will be the least expensive. Ask us about Numasizing!11 <strong>Numatics</strong> !"#$%&"'( ®Filter/Regulators (‘Piggybacks’)Combination filter/regulator performs the duties of both components inone compact unit. Also available as a coalescing filter-regulator.12 <strong>Numatics</strong> !"#$%&"'( ®Diverter BlockAllows air to be diverted into multiple directions. Can be used inmanifold or direct piped applications.13 <strong>Numatics</strong> !"#$%&"'( ®LubricatorAllows precise amount of lubricant to atomize <strong>and</strong> be sent downstreamin aerosol form. Useful for air motor or very high-cycle actuatorapplications.14 <strong>Numatics</strong> !"#$%&"'( ®Solenoid Soft StartQuick ExhaustSolenoid-activated soft start valve allows system to slowly ramp upto working pressure, preventing rapid acceleration from damagingcomponents. Downstream pressure quickly exhausts when solenoid isde-energized.15 ReclassifiersRemoves oil mist <strong>and</strong> reduces noise from exhaust ports on pneumaticvalves, cylinders, <strong>and</strong> air control systems at extremely high flow ratesInstrument CircuitModular Air Preparation System72dry service11Lubricated Cylinder Circuit5I/P,E/Ppressuretransducer4121086lubricated service14861439138151!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Particulate Filter!"#$%&"'( ®FRLSERIESF14, F22, F32, F42 Series Four convenient sizes 5 micron sintered elements st<strong>and</strong>ard (40 micron optional)ANSI SYMBOLAir Prep Can be installed as modular or individual unit Includes screws <strong>and</strong> o-rings for modular connection Manual or automatic drain Polycarbonate bowl st<strong>and</strong>ard Optional metal bowl with sight glass Optional CircleVision sight bowlSpecificationsBFlexiblok: Particulate FilterBowl 14 Series 22 series 32 Series 42 SeriesTemperature Range ºF (ºC)40-120(4-50)40-120(4-50)40-120(4-50)40-120(4-50)CEMax. Pressure PSIG(BAR)Poly C 150 (10) 150 (10) 150 (10) 150 (10)Metal 200 (14) 200 (14) 200 (14) 200 (14)ADFWeight lbs. (kg)Poly C 0.60 (0.28) 0.65 (0.30)Metal 0.65 (0.30)1.25(0.57)1.3(0.59)2.5(1.14)3.70(1.68)4.80(2.18)MOUNTING HOLESØ.200 TYP.2(Ø5.1)Nominal Flow SCFM (L/M)*32(906)65(1841)105 (2973)270(7647)Body Material Zinc Aluminum Aluminum AluminumDimensions: Inches (mm)*Nominal flow with a 5 micron element at 80 psig (5.5 bar) inlet <strong>and</strong> 5 psig(0.35 bar) pressure dropHow to OrderF 22 B – 04 ACSize A B C D E F142232425.94(151)7.41(186)8.88(221)12.6(32)1.45(37)1.82(48.5)2.45(62)3.26(83)0.85(22)1.045(26.5)1.35(34.3)1.4(36)1.68(43)2.375(60.4)3(76)4(102)1.6(41)2.165(54.9)3(76)4(102)0.21(5.3)0.14(3.6)ModelF = FilterSeries14 = 1.5 oz Bowl22 = 3.8 oz Bowl32 = 8.5 oz Bowl42 = 8.5 oz BowlElementB = 5 Micron ElementA = 40 Micron ElementThreads– = NPTFG* = G Tap (BSPP)R = PT (BSPT)*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1For complete modular FRL assemblies refer to pages 25-29OptionsA = Auto Drain (22, 32 <strong>and</strong> 42 Series)B = Flexible DrainC = CircleVision Sight BowlJ = External Pulse DrainM = Metal Bowl with Sight GlassQ = Metal Manual DrainR = Manual Lever DrainU = Dp IndicatorPort Size01 = 1/8 (14 Series)02 = 1/4 (14 or 22 Series)03 = 3/8 (22 Series)04 = 1/2 (22 or 32 Series)06 = 3/4 (32 or 42 Series)08 = 1 (42 Series)!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&49

!"#$%&"'( ®FRLSERIESCoalescing FilterAir PrepF14, F22, F32, F42 Series Four convenient sizes Cartridge element design Inner <strong>and</strong> outer support cores provide stability tofilter element Available with manual or automatic drain Optional metal bowl (sight glass available on 22, 32<strong>and</strong> 42 Series) Dp indicator st<strong>and</strong>ard on 14, 22, 32 <strong>and</strong> 42 SeriesANSI SYMBOLFlexiblok: Coalescing FilterSpecificationsBowl 14 Series 22 series 32 Series 42 SeriesTemperature Range ºF (ºC)Max. Pressure PSIG(BAR)Weight lbs. (kg)Nominal Flow SCFM (L/M)*How to Order40-120(4-50)40-120(4-50)40-120(4-50)40-120(4-50)Poly C 150 (10) 150 (10) 150 (10) 150 (10)Metal 200 (14) 200 (14) 200 (14) 200 (14)Poly C 0.65 (0.28) 0.66 (0.30)1.42(0.65)3.70(1.68)Metal 0.70 1.28 2.56 4.8012(340)18(510)48(1359)100(2832)Body Material Zinc Aluminum Aluminum Aluminum*Nominal flow with a 0.3 micron element at 80 psig (5.5 bar) inlet pressure<strong>and</strong> 1.5 psig (0.1 bar) pressure dropF 14 D - 02 ACACBDimensions: Inches (mm)DEFMOUNTING HOLESØ.200 TYP.2(Ø5.1)Size A B C D E F142232426.57(167)7.77(194)9.4(234)13.09(332)1.45(37)1.83(46.5)2.45(62)3.26(83)1.48(38)1.56(39.5)1.86(47)1.68(43)2.375(60.4)3(76)4(102)1.6(41)2.165(54.9)3(76)4(102)0.21(5.3)0.14(3.6)ModelF = FilterSeries14 = 1.5 oz Bowl22 = 3.8 oz Bowl32 = 8.5 oz Bowl42 = 8.5 oz BowlElementC = 0.7 Micron Coarse CoalescerD = 0.3 Micron Fine CoalescerE = 0.01 Micron Ultra Fine CoalescerF = Vapor adsorberThreads- = NPTFG* = G Tap (BSPP)R = PT (BSPT)OptionsA = Auto Drain (22, 32 <strong>and</strong> 42 Series)B = Flexible DrainC = Circlevision TM Sight BowlD = 3 Micron, Internal Pleated PrefilterJ = External Pulse DrainM = Metal Bowl With Sight GlassQ = Metal Manual DrainR = Manual Lever DrainU = No Dp IndicatorPort Size01 = 1/8 (14 Series)02 = 1/4 (14 or 22 Series)03 = 3/8 (22 Series)04 = 1/2 (22 or 32 Series)06 = 3/4 (32 or 42 Series)08 = 1 (42 Series)10*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1For complete modular FRL assemblies refer to pages 25-29!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Regulator!"#$%&"'( ®FRLSERIESR14, R22, R32, R42 Series Four convenient sizes High flow in compact size Locking non-rising adjustment knob Four different pressure ratings available Relieving or non-relieving modelsANSI SYMBOL(RELIEVING) Can be installed as modular or individual unit St<strong>and</strong>ard output pressure 0-125 PSIGANSI SYMBOL(NON-RELIEVING)Air PrepSpecificationsTemperature RangeºF (ºC)Max. Pressure PSIG(BAR)Nominal Flow RateSCFM (L/M)*How to OrderModelR = RegulatorSeries14223242StyleR = RelievingN = Non-RelievingK = Internal Check (22, 32, <strong>and</strong> 42 Series)P = Piston Operator (22, 32 <strong>and</strong> 42 Series)Threads- = NPTFG* = G Tap (BSPP)R = PT (BSPT)14 Series 22 Series 32 Series 42 Series40-120(4-50)40-120(4-50)40-120(4-50)40-120(4-50)250 (17) 200 (14) 250 (17) 250 (17)40(1133)70(1982)Weight lbs. (kg) 0.65 (0.30) 0.69 (0.31)100(2382)1.37(0.62)300(8495)4.30(1.95)Body Material Zinc Aluminum Aluminum Aluminum*Nominal flow at 100 psig (6.9 bar) inlet pressure <strong>and</strong> 80 psig (5.5 bar) setpoint pressureR 22 R - 04 GPSize A B C D E14223242A3.69(94)B4.51(115)5.95(151)8.19(208)CDimensions: Inches (mm)2.87(73)3.41(87)4.5(114)6.19(157)1.45(37)1.83(46.5)2.45(62)OptionsG = GaugeH = 0-200 PSIG Output (22, 32 or 42 Series)I = 0-25 PSIG OutputL = 0-60 PSIG OutputP = Panel Mount Nut (14, 22, 32 Series)S = Steel T H<strong>and</strong>le (42 Series)T = Tamper ResistantPort Size01 = 1/8 (14 Series)02 = 1/4 (14 or 22 Series)03 = 3/8 (22 Series)04 = 1/2 (22 or 32 Series)06 = 3/4 (32 or 42 Series)08 = 1 (42 Series)1/8 gauge ports3.26(83)MOUNTING HOLESØ.200 TYP.2(Ø5.1)D1.68(43)2.37560.43(76)4(102)E1.6(41)2.165(54.9)3(76)4(102)Flexiblok: Regulator*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1Notes:d withesistant cannot beused with high pressureFor complete modular FRL assemblies refer to pages 25-29!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&411

!"#$%&"'( ®FRLSERIESManifold RegulatorMR14 SeriesAir PrepThe 14 Series Manifold Regulator allows several regulators to bechained together while maintaining a constant primary pressure toeach regulator. This regulator features a dual spring design whichcovers any possible outlet setting without the need to indicate aspecific spring, eliminating confusing options <strong>and</strong> part numbers.The regulator uses the inner spring for more precise, lowerpressures, <strong>and</strong> the outer spring for middle to high pressures. Asthe smaller, inner spring is compressed, the larger, outer springtakes over for higher pressures.ANSI SYMBOL(RELIEVING)Flexiblok: Manifold RegulatorRegulators consist of a piston which floats between the mainsprings (top) <strong>and</strong> a valve stem (bottom). By turning the adjustmentknob clockwise, the main spring is forced onto the piston which,in turn, is pressed onto the valve stem. When the spring forcebecomes greater than the force of the air pressure in the controlchamber below the piston, the valve is forced down <strong>and</strong> flowbegins. As flow continues, the pressure begins to build <strong>and</strong> air, viathe aspirator tube, fills the control chamber. When the undersidepiston force is greater than the main spring force, the pistonis forced upward, causing the main valve to close. The cyclecontinues in a balanced process of reducing or increasing flowbased upon the downstream pressure. 3.68(94) Specifications14 Series.81(21)1.45 (37) 1.2 (31)Temperature Range ºF (ºC) 40-120 (4-50)Max. Pressure PSIG (BAR) 250 (17)Weight lbs. (kg) 0.60 (0.27)1.6(41)1/4 gauge portsMOUNTING HOLESØ.300 TYP.2 (Ø7.6)Body MaterialZincNominal Flow Rate SCFM (L/M)* 40 (1133)*Nominal flow at 100 psig (6.9 bar) inlet pressure <strong>and</strong> 90 psig(6.2bar) set pressure1.68 (43)How to OrderMR 14 R - 02 GTModelMR =Series14Manifold RegulatorStyleR = RelievingN = Non-RelievingThreads- = NPTFG* = G Tap (BSPP)R = PT (BSPT)OptionsG = GaugeI = 0-25 PSIG OutputL = 0-60 PSIG OutputP = Panel Mount NutT = Tamper ResistantPort Size02 = 1/412*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Miniature Manifold Regulator!"#$%&"'( ®FRLSERIESMR02 SeriesApplicationThe MR02 Series Miniature Manifold Regulator offers the flexibilitynecessary for many of today's applications. The MR02 Series allowsseveral regulators to be chained together while maintaining a constantprimary pressure to each regulator.A system equipped with the Miniature Manifold Regulator can help reduceoperation costs by reducing unnecessary downstream pressures <strong>and</strong>improve efficiencies by keeping them in one convenient location for easyadjustment.Features Can be installed as an individual or manifold unit St<strong>and</strong>ard output pressure 0 -125 PSIG 3 available outlet/gauge ports (one in front, one in back, <strong>and</strong> one in the bottom) Integral mounting holes allow for easy panel mounting Connects easily without adapters or independent manifold system St<strong>and</strong>ard 5 mm tamper resistant adjustment Relieving or non-relieving modelsSpecificationsP1 PortsOutlet/Gauge Ports1/8 NPTF10-32 UNFTemperature Range ºF (ºC) 40-120 (4-50)Max. Inlet Pressure PSIG (BAR) 200 (14)Weight lbs. (g) 15 (68)**SCFM w/100 PSI inlet set @ 75**SCFM w/100 PSI inlet set @ 60**SCFM w/100 PSI inlet set @ 40Body Material** based on a 25% pressure drop from setOptional <strong>Accessories</strong>Item23mm Gauge "G" Option5 SCFM4 SCFM3 SCFMAluminumPart No.NG23-M10-32 - 1/8 NPTF Adapter 134-03410-32 - 1/8 O.D Barb Fitting 134-23610-32 - 1/4 O.D Barb Fitting 134-234ANSISYMBOL(Relieving)FrontMR02R-01G picturedshown assembled <strong>and</strong> individuallyANSISYMBOL(Non-Relieving)SideAir PrepFlexiblok: Miniature Manifold RegulatorEach Regulator includes an R02K assembly kit whichincludes (1) 10-32 pipe plug, (1) 1/8 pipe plug, (1) P1 porto-ring, (2) connector screws.How to OrderMR 02 R - 01 GModelMR = Manifold RegulatorSeries02StyleR = RelievingN = Non-RelievingOptionsG = GaugeI = 0-25 PSIL = 0-60 PSIPort Size01 = 1/8P1 ports are 1/8outlet/gauge ports are 10-32Threads- = NPTFG = G Tap (BSPP)R = PT (BSPT)!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&413

!"#$%&"'( ®FRLSERIESRegulator - Pilot OperatedR22, R32, R42 SeriesAir Prep Three convenient sizes High flow in compact sizeANSI SYMBOL Can be installed as modular or individual unit St<strong>and</strong>ard output pressure 0-125 PSIG Relieving or non-relieving modelsFlexiblok: Regulator - Pilot OperatedSpecificationsTemperature Range ºF (ºC)22 Series 32 Series 42 Series40-120(4-50)40-120(4-50)40-120(4-50)Min. Pilot Pressure PSI (BAR) 15 (1) 15 (1) 15 (1)Max. Pilot Pressure PSI (BAR) 150 (10.2) 150 (10.2) 250 (17.2)Nominal Flow RateSCFM (L/M)*60(1699)Weight lbs. (kg) 0.66 (0.25)110(3115)1.35(0.50)325(9203)3.85(1.75)Body Material Aluminum Aluminum AluminumACB*Nominal flow at 100 psig (6.9 bar) inlet pressure <strong>and</strong> 80 psig (5.5 bar)set pressure1/8 pilot port1/8 gauge portsMOUNTING HOLESØ.200 TYP.2(Ø5.1)EDDimensions: Inches (mm)Size A B C D E223.12(79)2.12(55)1.83(46.5)2.375(60.4)2.165(54.9)323.93(100)2.58(65.5)3(76)3(76)3(76)How to Order423(76)2.601(66)4(102)4(102)4(102)R 32 W - 04 GModelR = RegulatorSeries223242StyleW = All Pilot Operated RegulatorsThreads- = NPTFG* = GTap (BSPP)R = PT (BSPT)OptionsG = GaugeN = Non-RelievingPort Size02 = 1/4 (22 Series)03 = 3/8 (22 Series)04 = 1/2 (22 or 32 Series)06 = 3/4 (32 <strong>and</strong> 42 Series)08 = 1 (42 Series)14*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1For complete modular FRL assemblies refer to pages 25-29.!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Particulate Filter/Regulator!"#$%&"'( ®FRLSERIESP14B, P22B, P32B, P42B Series Four convenient sizes 5 micron element st<strong>and</strong>ard (40 micron optional) Can be installed as individual or modular unit Locking non-rising adjustment knob Optional CircleVision sight bowl Optional metal bowl (sight glass available on 22, 32 <strong>and</strong>42 Series) St<strong>and</strong>ard output pressure 0-125 PSIG Bowl seal held captive (22, 32, <strong>and</strong> 42 Series)SpecificationsBowl 14 Series 22 series 32 Series 42 SeriesTemperature Range ºF (ºC)Max. Pressure PSIG(BAR)Weight lbs. (kg)Nominal Flow SCFM (L/M)*How to Order40-120(4-50)40-120(4-50)40-120(4-50)40-120(4-50)Poly C 150 (10) 150 (10) 150 (10) 150 (10)Metal 200 (14) 200 (14) 200 (14) 200 (14)Poly C 0.75 (0.34) 0.91 (0.41)Metal0.80(0.37)40(1133)1.50(0.68)1.81(0.82)2.99(1.34)60 (1699) 90 (2549)5.05(2.29)6.15(2.79)300(8496)Body Material Zinc Aluminum Aluminum Aluminum*Nominal flow using a 5 micron element, at 100 psig (6.9 bar) inlet pressure<strong>and</strong> 80 psig (5.5 bar) set pressureP 14 B - 02 GIPANSI SYMBOLABC1/8 gauge portsMOUNTING HOLESØ.200 TYP.2(Ø5.1)Size A B C D E142232427.9(200)9.86(251)12.2(309)17.39(442)2.87(73)3.41(87)4.5(114)6.19(157)1.45(37)1.83(46.5)2.45(62)3.26(83)DDimensions: Inches (mm)E1.68(43)2.375(60.4)3(76)4(102)1.6(41)2.165(54.9)3(76)4(102)Air PrepFlexiblok: Particulate Filter/RegulatorModelP = Particulate/RegulatorSeries14 = 1.5 oz Bowl22 = 3.8 oz Bowl32 = 8.5 oz Bowl42 = 8.5 oz BowlElementB = 5 Micron ElementA = 40 Micron ElementThreads- = NPTFG* =G Tap (BSPP)R = PT (BSPT)Port Size01 = 1/8 (14 series)02 = 1/4 (14 or 22 series)03 = 3/8 (22 series)04 = 1/2 (22 or 32 series)06 = 3/4 (32 or 42 series)08 = 1 (42 series)*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1OptionsA** = Auto Drain (22, 32, <strong>and</strong> 42 Series)B = Flexible DrainC = CircleVision Sight BowlG = GaugeH** = 0-200 PSIG Output (22, 32 <strong>and</strong> 42 Series)I = 0-25 PSIG OutputJ = External Pulse DrainL = 0-60 PSIG Output (22, 32 <strong>and</strong> 42 Series)M = Metal Bowl (Sight Glass Available 22, 32 <strong>and</strong> 42 Series)N = Non-RelievingP = Panel Mount Nut (14, 22, <strong>and</strong> 32 Series)Q = Metal Manual DrainR = Manual Lever DrainT = Tamper ResistantS = Steel T H<strong>and</strong>le (42 Series)V = Shut off valve**“A” <strong>and</strong> “H” options cannot be used together.Notes:To order a piston style particulate filter/regulator,add “P” to the model number.(example: P32BP-04GIP)esistant cannot be used with highpressure “H” option with 42 Series.For complete modular FRL assemblies refer to pages 25-29.!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&415

!"#$%&"'( ®FRLSERIESCoalescing Filter/RegulatorC14, C22, C32, C42 SeriesAir Prep Four convenient sizes Cartridge element designANSI SYMBOL Inner/outer support cores prevent element from crushingin either flow direction Four element grades availableFlexiblok: Coalescing Filter/RegulatorSpecificationsBowl 14 Series 22 series 32 Series 42 SeriesTemperature Range ºF (ºC)Max. Pressure PSIG(BAR)Weight lbs. (kg)Nominal Flow SCFM (L/M)*40-120(4-50)40-120(4-50)40-120(4-50)40-120(4-50)Poly C 150 (10) 150 (10) 150 (10) 150 (10)Metal 200 (14) 200 (14) 200 (14) 200 (14)Poly C 0.80 (0.35) 0.92 (0.42)Metal0.85(0.38)20(560)1.60(0.73)35(991)1.82(0.83)2.95(1.34)50(1416)5.05(2.29)6.15(2.76)100(2832)ABC1/8 gauge portsMOUNTING HOLESØ.200 TYP.2(Ø5.1)DEBody Material Zinc Aluminum Aluminum Aluminum*Nominal flow using a 0.3 micron element, at 100 psig (6.9 bar) inletpressure <strong>and</strong> 80 psig (5.5 bar) set pressureHow to OrderC32 C - 06 AGMDimensions: Inches (mm)Size A B C D E142232427.9(200)9.86(251)12.2(309)17.39(442)2.87(73)3.41(87)4.5(114)6.19(157)1.45(37)1.83(46.5)2.45(62)3.26(83)1.68(43)2.375(60.4)3(76)4(102)1.6(41)2.165(54.9)3(76)4(102)ModelC = Coalescer/RegulatorSeries14 = 1.5 oz Bowl22 = 3.8 oz Bowl32 = 8.5 oz Bowl42 = 8.5 oz BowlElementC = 0.7 Micron Coarse CoalescerD = 0.3 Micron Fine CoalescerE = 0.01 Micron Ultra Fine CoalescerF = Vapor AdsorberThreads- = NPTFG* =G Tap (BSPP)R = PT (BSPT)Port Size01 = 1/8 (14 series)02 = 1/4 (14 or 22 series)03 = 3/8 (22 series)04 = 1/2 (22 or 32 series)06 = 3/4 (32 or 42 series)08 = 1 (42 series)OptionsA* = Auto Drain (22, 32, <strong>and</strong> 42 series)B = Flexible DrainC = CircleVision Sight BowlD = 3 Micron, Internal Pleated FilterG = GaugeH* = 0-200 PSIG OutputI = 0-25 PSIG OutputJ = External Pulse DrainL = 0-60 PSIG OutputM = Metal Bowl (Sight Glass Available 22, 32 <strong>and</strong> 42 Series)N = Non-RelievingP = Panel Mount NutQ = Metal Manual DrainR = Manual Lever DrainS = Steel T H<strong>and</strong>le (42 Series)T = Tamper ResistantV = Shut Off Valve*‘A” <strong>and</strong> “H” options cannot be used together.Note: To order a piston style coalescing/regulatoradd “P” to the model number. (ie: C32CP-06AGQ)16*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1For complete modular FRL assemblies refer to pages 25-29.!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Lubricator!"#$%&"'( ®FRLSERIESL14L, L22L, L32L, L42L Series Four convenient sizes Lubrication to begin at 2 SCFM Can be filled under pressure (32 <strong>and</strong> 42 series) Tamper-resistant knob st<strong>and</strong>ard Optional CircleVision sight bowl Optional metal bowl (sight glass available on 22, 32, <strong>and</strong>42 series) Can be mounted as individual or modular unit Button head fill optional on all sizes Atomizing chamber develops longer life aerosolsANSI SYMBOLAir PrepSpecificationsTemperatureRange ºF (ºC)Max. PressurePSIG (BAR)Nominal Flow RateSCFM (L/M)*Weight lbs. (kg)14 Series 22 Series 32 Series 42 Series40-120(4-50)200(14)30(850)0.60(0.27)40-120(4-50)200(14)95(2690)0.69(0.31)40-120(4-50)200(14)230(6513)1.37(0.62)40-120(4-50)200(14)240(6796)4.15(2.18)Body Material Zinc Aluminum Aluminum Aluminum*Nominal flow at 80 psig (5.5 bar) inlet pressure <strong>and</strong>5 psig (0.35 bar) pressure dropABCDDimensions: Inches (mm)EMOUNTING HOLESØ.200 TYP.2(Ø5.1)Size A B C D E142232426.65(169)8.12(206)9.65(245)13.27(337)2.24(88)2.41(61)2.72(70)2.72(70)1.45(37)1.83(46.5)2.45(62)3.26(83)1.68(43)2.375(60.4)3(76)4(102)1.6(41)2.165(54.9)3(76)4(102)Flexiblok: LubricatorHow to OrderL 22 L - 02 MModelL = LubricatorSeries14 = 1.5 oz Bowl22 = 3.8 oz Bowl32 = 3.8 oz Bowl42 = 3.8 oz BowlStyleL = St<strong>and</strong>ard LubricatorsThreads- = NPTFG* = G Tap (BSPP)R = PT (BSPT)OptionsC = CircleVision Sight BowlF = Button Head FillK = Drain on BowlM = Metal Bowl (Sight Glass Available on 22, 32, <strong>and</strong> 42 Series)Port Size01 = 1/8 (14 series)02 = 1/4 (14 or 22 series)03 = 3/8 (22 series)04 = 1/2 (22 or 32 series)06 = 3/4 (32 or 42 series)08 = 1 (42 series)Note: F <strong>and</strong> K options cannot be used together.*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1For complete modular FRL assemblies refer to pages 25-29.!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&417

!"#$%&"'( ®FRLSERIESSolenoid Soft StartQuick Exhaust ValveAir PrepFlexiblok: Solenoid Soft Start/Quick ExhaustValves18S22C, S32C, S42C Series Three convenient sizes Lockout feature prevents unauthorized pressurization ofsystem High exhaust capacity for quick depletion of pressure High inlet to outlet flow capability Connects easily to !"#$%&"'( ®Modular system <strong>Incorporated</strong> metering valve controls how quicklydownstream pressure is reached, which controls theslow start featureSpecificationsExhaust Ports NPTF (GaugePorts NPTF)Wattage <strong>and</strong> Amperage110V AC230V AC24V AC24V DC1.42 watts / 0.022 amps2.00 watts / 0.016 amps2.00 watts / 0.011 amps2.00 watts / 0.080 ampsHow to OrderModelS = Solenoid Soft StartSeries223242StyleC = St<strong>and</strong>ard Solenoid Soft StartThreads- = NPTFG* = G Tap (BSPP)R = PT (BSPT)22 Series 32 Series 42 Series1/2 (1/8) 1/2 (1/4)*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1ADFE3/8: 3 exh.ports (1/4)Temperature Range ºF (ºC) 40-120 (4-50) 40-120 (4-50) 40-120 (4-50)Min. Pressure PSI (BAR) 60 (4) 60 (4) 20 (1.38)Max. Pressure PSIG (BAR) 150 (10) 150 (10) 150 (10)Weight lbs. (kg) 0.94 (0.43) 1.56 (0.71) 4.35 (1.97)Body Material Aluminum Aluminum AluminumBGCANSI SYMBOL1/8 gauge portsMOUNTING HOLESØ.200 TYP.2(Ø5.1)S 32 C - 06 B EGMJ!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4HISize A B C D F G2232Series0.51(13)0.26(6)42 N/AFor complete modular FRL assemblies refer to pages 25-29.Dimensions: Inches (mm)2.9(73)3.25(82)4.0(102)OptionsE = 110V AC 50/60 HzF = 230V AC 50/60 HzG = GaugeJ = 24V AC 50/60 Hz CoilK = 24V DC CoilL = Plug with LightM = MufflerN = No manual OverrideP = Black Plug AssemblyQ = 4 Pin Micro ConnectorX = No SlideRevision LevelBIn/Out2.1(65)3.0(76)4.0(102)Port Size02 = 1/4 (22 Series)03 = 3/8 (22 Series)04 = 1/2 (22 or 32 Series)06 = 3/4 (32 or 42 Series)08 = 1 (42 Series)Cv Flow Factor6.3(160)6.9(168)7.4(188)Out/Exhaust22 Series 1/4 2.0 1.222 Series, 3/8 2.87 1.3822 Series, 1/2 3.62 1.3832 Series, 1/2 5.24 3.0132 Series, 3/4 6.47 3.1442 Series, 1 8.0 5.02.2(58)2.7(68)2.0(51)1.8(46)2.45(62)3.26(83)

Solenoid Quick Exhaust Valve!"#$%&"'( ®FRLSERIESS14E, S22E, S32E, S42E Series Four convenient sizes Lockout feature (located in slide valve) prevents unauthorizedpressurization of system (22, 32, <strong>and</strong> 42 Series) St<strong>and</strong>ard manual override (optional without manual override) Low-wattage coil High exhaust capacity for quick depletion of pressure High inlet to outlet flow capability Connects easily to !"#$%&"'( ®Modular systemSpecificationsExhaust Ports NPTF (GaugePorts NPTF)Wattage <strong>and</strong> Amperage110V AC230V AC24V AC24V DC1.42 watts / 0.022 amps2.00 watts / 0.016 amps2.00 watts / 0.011 amps2.00 watts / 0.080 ampsMOUNTING HOLES22: Ø.200 TYP.2(Ø5.1)32: Ø.281 TYP.2(Ø7.2)ANSI SYMBOL14 Series 22 Series 32 Series 42 Series1/8 (10-32 UNF) 1/2 (1/8) 1/2 (1/4) 3/4 (1/4)Temperature Range ºF (ºC) 40-120 (4-50) 40-120 (4-50) 40-120 (4-50) 40-120 (4-50)Min. Pressure PSI (BAR) 40 (2.76) 40 (2.76) 40 (2.76) 20 (1.38)Max. Pressure PSIG (BAR) 150 (10) 150 (10) 150 (10) 150 (10)Weight lbs. (kg) 1.25 (0.57) 1.15 (0.53) 1.75 (0.79) 3.45 (1.56)Body Material Zinc Aluminum Aluminum AluminumDimensions: Inches (mm)Size A B C D E F G H I J2232.51(13).25(6)42 N/A2.9(73)3.2(82)4.0(102)2.1(65)3.0(76)4.0(102)6.3(160)6.9(168)7.4(188).32(8).5(13).49(12)Series2.2(58)2.7(68)2.47(63)1.8(46)2.4(61)3.26(83)In/OutCv Flow Factor4.4(112)4.7(121)5.4(127)Out/Exhaust14 Series 1/4 1.55 1.1022 Series, 1/4 2.0 1.222 Series, 3/8 2.87 1.3822 Series, 1/2 3.62 1.3232 Series, 1/2 5.24 3.0132 Series, 3/4 6.47 3.1442 Series, 1 8.0 5.01.9(48)2.1(55)2.0(51)1.5(40)2.0(51)3.2(81)Air PrepFlexiblok: Solenoid Quick Exhaust ValveHow to OrderS 32 E - 04 B EGMModelS = Solenoid Quick ExhaustSeries14223242StyleE = St<strong>and</strong>ard Solenoid Quick Exhaust ValveThreads- = NPTFG* = G Tap (BSPP)R = PT (BSPT)*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1OptionsE = 110V AC 50/60 HzF = 230V AC 50/60 HzG = GaugeJ = 24V AC 50/60 Hz CoilK = 24V DC CoilL = Plug with LightM = MufflerN = No manual OverrideP = St<strong>and</strong>ard Black Plug AssemblyQ = 4 Pin Micro ConnectorX = No SlideRevision LevelBPort Size01 = 1/8 (14 Series)02 = 1/4 (14 or 22 Series)03 = 3/8 (22 Series)04 = 1/2 (22 or 32 Series)06 = 3/4 (32 or 42 Series)08 = 1 (42 Series)For complete modular FRL assemblies refer to pages 25-29.!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&419

!"#$%&"'( ®FRLSERIESInternally/Externally Pilot OperatedQuick Exhaust ValvesFlexiblok: Int/Ext Pilot Operated Quick ExhaustValvesAir PrepPilot Operated “Soft Start” Quick Exhaust ValvesExternal Pilot - Style “C” – Available in three series S22, S32, S42Pilot Operated “Soft Start” Quick Exhaust ValvesInternal Pilot - Style “P” – Available in three series S22, S32, S42Pilot Operated “Quick Exhaust” ValvesExternal Pilot - Style “E” – Available in four series S14, S22, S32, S42 Lockout feature (located in yellow slide valve) preventsunauthorized system pressurization. Available in threeseries S22, S32, S42 only High flow capacity Inlet to Outlet High exhaust capacity for quick depletion of downstreampressure Connects easily to !"#$%&"'( ®Modular FRL systemsSpecificationsExhaust Ports NPTF(Gauge Ports NPTF)14 Series 22 Series 32 Series 42 Series1/4(10-32 UNF)1/2(1/8)1/2(1/4)3/4(1/4)Temperature Range ºF (ºC) 40-120 (4-50) 40-120 (4-50) 40-120 (4-50) 40-120 (4-50)Min. Pressure PSI (BAR) 40 (2.76) 40 (2.76) 40 (2.76) 40 (2.76)Max. Pressure PSIG (BAR) 150 (10) 150 (10) 150 (10) 150 (10)Weight, lbs. (kg.) 1.25 (0.57) 1.15 (0.53) 1.75 (0.79) 3.45 (1.56)Body Material Zinc Aluminum Aluminum AluminumANSI SYMBOLMeteringValveSpoolAir Piloted Soft Start Quick Exhaust ValveSeriesAir Piloted Quick Exhaust ValveIn/OutCvOut/Exhaust14 Series 1/4 1.55 1.1022 Series, 1/4 2.0 1.222 Series, 3/8 2.87 1.3822 Series, 1/2 3.62 1.3232 Series, 1/2 5.24 3.0132 Series, 3/4 6.47 3.1442 Series, 1 8.0 5.0How to OrderS 22 E - 04 B GMWModelS = Internally or Externally PilotOperated Quick Exhaust ValvesSeries14223242StyleC = Soft Start Quick Exhaust Valves(External Pilot 22, 32, 42 Series)P = Soft Start Quick Exhaust Valves(Internal Pilot 22, 32, 42 Series)E = Quick Exhaust Valves(External Pilot 14, 22, 32, 42 Series)Threads- = NPTFG* = G Tap (BSPP)R = PT (BSPT)*Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1OptionsG = GaugeM = MufflerW = External Air Pilot (Use for styles “C & E”)X = No Slide on ValveRevision LevelBPort Size01 = 1/8 (14 Series)02 = 1/4 (14 or 22 Series)03 = 3/8 (22 Series)04 = 1/2 (22 or 32 Series)06 = 3/4 (32 <strong>and</strong> 42 Series)08 = 1 (42 Series)Note: How to order examples for the three different models:"C" Externally Piloted Soft Start Quick Exhaust Valve: eg S22C-04BW"P" Internally Piloted Soft Start Quick Exhaust Valve: eg S22P-04"E" Externally Piloted Quick Exhaust Valve: eg S22E-04BW“ C & E ”externally pilot operated valves are not field convertible tosolenoid operated. Consult factory.20For complete modular FRL assemblies refer to pages 25-29.!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Internally/Externally Pilot OperatedQuick Exhaust Valves!"#$%&"'( ®FRLSERIES14 Series Internally/Externally Piloted Quick Exhaust ValveS14*-04BW (14 Series Pilot Operated Quick Exhaust Valve)Air Prep10-32 gauge ports22 <strong>and</strong> 32 Series Internally/Externally Piloted Quick Exhaust ValveABC22: 1/8 gauge ports32: 1/4 gauge portsMOUNTING HOLES22: Ø.200 TYP.2(Ø5.1)32: Ø.281 TYP.2(Ø7.2)pressure dropair flowS22*-04BW (22 Series Pilot Operated Soft Start Quick Exhaust Valve)pressure dropFlexiblok: Int/Ext Pilot Operated Quick ExhaustValvesair flowHS32*-06BW (32 Series Pilot Operated Soft Start Quick Exhaust Valve)DEFGJIpressure dropDimensions: Inches (mm)air flowA B C D E F G H I J22 Series .51 (13) 2.9 (73) 2.1 (65) 5.2 (132) .32 (8) 2.2 (58) 1.8 (46) 3.3 (84) 1.9 (48) 1.5 (38)32 Series .25 (6) 3.2 (82) 3.0 (76) 5.8 (147) .5 (13) 2.7 (68) 2.4 (61) 3.6 (93) 2.6 (55) 2.0 (51)42 Series Internally/Externally Piloted Quick Exhaust Valve6.29.634.004.001/4 gauge portsMOUNTING HOLESØ.257 TYP.2(Ø6.5)S42*-08BW (42 Series Pilot Operated Soft Start Quick Exhaust Valve)pressure dropPSIDBAR-3-2-15432160PSIG4 BAR90PSIG4 BAR100PSIG4 BAR* Muffler not included2.472.003.263.200SCFM 0 20 40 60 80 100 120 140 160 180dm /s10 20 30 40 50 60 70 80!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4air flow21

!"#$%&"'( ®FRLSERIESShut Off ValveVS14, VS22, VS32, VSL42 Series14, 22, 32 SeriesAir PrepThe !"#$%&"'( ®Shut-Off Valve is an easy <strong>and</strong> inexpensive wayto add shut off capability to an FRL. The valve includes a lockoutfeature designed for a padlock to prevent unauthorized downstreampressurization during maintenance. The shut off valve is usually mountedfirst in the assembly.Flexiblok: Shut Off Valve <strong>and</strong> Lockout-QuickExhaust ValveMax. inlet pressure: 200 PSI (13.7 bar)250 PSI (17 bar) - 42 Series Relieves downstream pressure when closed Lockout feature prevents unauthorized pressurization of systemModel #s Dimensions Flow RatesNPTF BSPP BSPT A B C D Ports SCFM L/M14VS14-01 VS14G01 VS14R01 1.63 (41) 1.6 (41) 1.6 (41) 3 (76) 1/8VS14-02 VS14G02 VS14R02 1.63 (41) 1.6 (41) 1.6 (41) 3 (76) 1/433 934VS22-02 VS22G02 VS22R02 2.0 (50) 2.16 (55) 1.86 (47) 3.1 (79) 1/422 VS22-03 VS22G03 VS22R03 2.0 (50) 2.16 (55) 1.86 (47) 3.1 (79) 3/8 67 1897VS22-04 VS22G04 VS22R04 2.0 (50) 2.16 (55) 1.86 (47) 3.1 (79) 1/232VS32-04 VS32G04 VS32R04 2.25 (57) 3.0 (76) 2.57 (65) 4.2 (107) 1/2VS32-06 VS32G06 VS32R06 2.25 (57) 3.0 (76) 2.57 (65) 4.2 (107) 3/4132 373842VSL42-06 VSL42G06 VSL42R06 3.2 (83) 4.0 (102) 4.8 (122) 9.3 (236) 3/4VSL42-08 VSL42G08 VSL42R08 3.2 (83) 4.0 (102) 4.8 (122) 9.3 (236) 1155 438942 SeriesCDABNOTE: Add “N” to end of model number for non-relieving model (i.e. VS14-01N)(Not available on 42 series models).Quick Exhaust Lockout ValveMVL42/MVT42 Series Rugged all metal design Placed last in an air preparationassembly. To be used as a systemquick exhaust valve.*Additional information can be found inthe Shut Off/Lock out valve section ofthe catalog.ANSI SYMBOLSSpecificationsTemperature Range: 40-120°F (4-50°C)Max. Pressure: 250 PSIG (17 bar)Weight: 4.95 lbs (2.25 kg)9.98(236)10.98(279)4.00(102)4.00(102)22CV RatingsModel #CvIn/OutCvOut/ExhaustMVL42-06Y 11.5 9MVL42-08Y 12.5 10MVT42-06Y 11.5 9MVT42-08Y 12.5 10How to OrderModelMVL = St<strong>and</strong>ardMVT = Slo-Start FeatureSeries42!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&43.26(83)MVL 42 – 08 _ Y3.26(83)OptionsA = Metal Muffler (ie MVT42-08AY)B = Scissor Lockout (ie MVT42-08BY)Port Size06 = 3/408 = 1Threads– = NPTFG = G Tap (BSPP)(Conforms to ISO St<strong>and</strong>ards 1179-1 <strong>and</strong> 228-1)R = PT (BSPT)

Diverter Block <strong>and</strong> End Plates!"#$%&"'( ®FRLSERIESDK14, DK22, DK32, DK42 Series - Diverter BlocksDesigned to give !"#$%&"'( ®components total versatility, the diverter blockmounts directly in line with the FRL combination. Additional componentscan then be manifold mounted in a compact manner that doesn’t causeexcessive pressure drop. There are two available tapped ports per unit.Max. inlet pressure: 200 PSI (13.7 bar) (14, 22, 32 Series)250 PSI (17 bar) (42 Series)Air PrepModel #Dimensions inches (mm)Series NPTF BSPP BSPT A B C D EPorts14 DK14-02 DK14G02 DK14R02 1.72 (44) 1.54 (39) 1.6 (41) 1/4 1/8 Tapped 1/4 NPTF In & Out with two 1/8 NPTF branches22 DK22-03 DK22G03 DK22R03 2.16 (55) 2.00 (50) 2.16 (55) 1/2 3/8 Tapped 1/2 NPTF in & out with two 3/8 NPTF branches32 DK32-04 DK32G04 DK32R04 3.00 (76) 2.70 (69) 3.00 (76) 3/4 1/2 Tapped 3/4 NPTF in & out with two 1/2 NPTF branches42 DK42-06 DK42G06 DK42R06 4.00 (102) 3.40 (87) 4.00 (102) 3/4 3/4 In & Out <strong>and</strong> branches 3/4 with two 3/4 NPTF branches42 DK42-08 DK42G08 DK42R08 4.00 (102) 3.40 (87) 4.00 (102) 1 1 In & Out <strong>and</strong> branches 1 with two 1 NPTF branchesHK14, HK22, HK32 Series - Diverter PlatesDiverter plates are designed to provide air signals in a compact space.Used individually or in combination, they can be used with gauges orswitches to determine a pressure or pressure signal.Max. inlet pressure: 200 PSI (13.7 bar)Flexiblok: Diverter Blocks & End PlatesModel #Dimensions inches (mm)Series NPTF BSPP BSPT A B C Outlet PortApplication14 HK14-01 HK14G01 HK14R01 1.54 (39) 1.50 (38) .75 (19) 1/8 Mounts between two units22 HK22-01 HK22G01 HK22R01 2.00 (51) 2.15 (55) .75 (19) 1/8 Mounts between two units32 HK32-01 HK32G01 HK32R01 3.00 (76) 3.00 (76) .75 (19) 1/8 Mounts between two unitsRear-Ported End PlatesMR32 SeriesEnd PlatesMK42 Series1.03(26).10(3).75(19)Available only in the 32 Series, the Rear-Ported End Plate allows anFRL to be mounted flush with a surface <strong>and</strong> the piping to exit the rearof the combination.Max. inlet pressure: 200 PSI (13.7 bar)How to OrderModel Number Style NPTF DescriptionMR32A A 1/2 Left rear portingMR32B B 1/2 Right side rear portingMR32AB A/B 1/2 Both rear ported plates5.55(141) 3.40(86)4.00(102)5.14(130)!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&45.17(132)3.05(77).38(10)1.25(32).63(16)1.80(46)The 42 series easy slide end plate <strong>and</strong> mounting bracket kit is aunique option allowing a full FRL assembly to be quickly added orremoved.Max. inlet pressure: 250 PSI (17 bar)How to OrderPortSizeModel #NPTF BSPP BSPT3/4 MK42AB-06 MK42ABG06 MK42ABR061 MK42AB-08 MK42ABG08 MK42ABR0823

!"#$%&"'( ®FRLSERIESBowl Drain OptionsAir PrepBowl Drain OptionsAutomatic Float Drain - ‘A’ OptionThe Auto Float Drain isinstalled into the bottomof the filter bowl. As theliquid level inside the bowlincreases, the tire-like floatlifts, allowing the liquid todrain. This drain shouldnot be used in applicationsexceeding 175 PSI.Flexible Drain - ‘B’ OptionThe Flexible Drain is aseasy to use as pushingthe stem to one side <strong>and</strong>allowing contents to expel.A popular option due to lowcost <strong>and</strong> ease of use. Thisdrain should not be usedin applications exceeding125 PSI.Flexiblok: Bowl Drain OptionsModelAKF00AKF02External Pulse Drain - ‘J’ OptionThe External Pulse Drain isdesigned for use in the 12,14 <strong>and</strong> 42 Series bowl butalso works with the 22 <strong>and</strong>32 Series. This inexpensive<strong>and</strong> reliable drain features anincorporated barbed fittingwhich fits 3/16 ID tubing foreasy drainage of liquid <strong>and</strong>contaminant.ModelJKF02IDF-01For Series22, 32, 42 SeriesAutodrain only22, 32, 42 Series(inc. drain, bushing,o-ring)For Series12,14, 22, 32, 42Series (includesbushing kit)drain onlyMetal Manual Drain - ‘Q’ OptionModelBKF02The Metal Manual Drain isa newer drain option for the!"#$%&"'( ® line. Simplyturn the drain counterclockwiseto expel bowlcontents. St<strong>and</strong>ard on 50<strong>and</strong> 70 Series.ModelQKF02For Series14, 22, 32,42 Series (inc.flexible rubberexterior <strong>and</strong> innerstem)For Series14, 22, 32, 42Series (inc. drain,retaining clip,bushing, o-ring)Manual Lever Drain - ‘R’ OptionThe Manual Lever Drainallows for convenience <strong>and</strong>ease of use. Press down onthe white lever to manuallydrain bowl contents.Available for all !"#$%&"'( ®filters.Manual Drain (St<strong>and</strong>ard):Manual Drain (St<strong>and</strong>ard): This st<strong>and</strong>ard product isequipped with an internal barb fitting (1/4" I.D.) fordrain tube connection.ModelRKF02For Series14, 22, 32, 42Series Filters (inc.drain, bushing, clip,o-ring)24!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Air Prep FRL Assemblies!"#$%&"'( ®FRLSERIES)*'+(&"'( <strong>FRLs</strong> in st<strong>and</strong>ard combinations)*'+(&"'( assemblies utilize one model number for st<strong>and</strong>ardconfigurations, complete with gauges. Each component is factoryassembled <strong>and</strong> tested.Air PrepEach of the st<strong>and</strong>ard )*'+(&"'( combinations is a completeassembly. Bowl, drain, <strong>and</strong> fill options are available where applicable.Additional options are not available <strong>and</strong>, if required, components canbe ordered as a ,'-.&"'( combination (see page 29).To order any of the )*'+(&"'( models without the Shut-Off Valve,replace the “V” in the part number with an “X” (i.e. M22-03XFCXX).See individual component pages for specifications <strong>and</strong> dimensions.Shut Off/Particulate Filter/Regulator/Lubricator (with Gauge)Model #Shut OffParticulateFilterRegulatorLubricatorM14-01VFRLX VS14-01 F14B-01 R14R-01G L14L-01M14-02VFRLX VS14-02 F14B-02 R14R-02G L14L-02M22-02VFRLX VS22-02 F22B-02 R22R-02G L22L-02M22-03VFRLX VS22-03 F22B-03 R22R-03G L22L-03M22-04VFRLX VS22-04 F22B-04 R22R-04G L22L-04M32-04VFRLX VS32-04 F32B-04 R32R-04G L32L-04M32-06VFRLX VS32-06 F32B-06 R32R-06G L32L-06M42-06VFRLX VSL42-06 F42B-06 R42R-06G L42L-06M42-08VFRLX VSL42-08 F42B-08 R42R-08G L42L-08*All )*'+(&"'( model # assemblies on the nextfew pages are called out as NPT. For BSPP modelsreplace the "-" with a "G". For BSPT models replace"-" with an "R"Dimensions: Inches (mm)14 Series:A 7.90 (200) B 5.84 (148) C 6.72 (172) D 3.1 (74)22 Series:A 10.02 (255) B 7.62 (194) C 9.32 (237) D 3.42 (87)32 Series:A 12.32 (313) B 9.12 (232) C 11.25 (286) D 4.10 (104)42 Series:A 17.4 (442) B 12.6 (320) C 16.0 (406) D 5.3 (135)Flexiblok: StockBlok* To order this )*'+(&"'( model without a shutoff valve,replace the "V" in the model number with an "X" (ie.M42-08XFRLX).A = Auto Drain (22, 32, 42 Series only)B = Flexible DrainC = CircleVision Sight BowlE = Endplates (42 Series only)J = External Pulse DrainM = Metal Bowls w/ Sight GlassF = Lubricator Quick FillQ = Metal Manual DrainR = Manual Lever DrainShut Off/Particulate Filter-Regulator/Diverter Block/Lubricator (with Gauge)Model #* To order this )*'+(&"'( model without a shutoff valve,replace the "V" in the model number with an "X" (ie.M42-08VPDLX).Shut OffParticulateFilter-RegulatorDiverterBlockLubricatorM14-01VPDLX VS14-01 P14B-01G DK14-02 L14L-01M14-02VPDLX VS14-02 P14B-02G DK14-02 L14L-02M22-02VPDLX VS22-02 P22B-02G DK22-03 L22L-02M22-03VPDLX VS22-03 P22B-03G DK22-03 L22L-03M22-04VPDLX VS22-04 P22B-04G DK22-03 L22L-04M32-04VPDLX VS32-04 P32B-04G DK32-04 L32L-04M32-06VPDLX VS32-06 P32B-06G DK32-04 L32L-06M42-06VPDLX VSL42-06 P42B-06G DK42-06 L42L-06M42-08VPDLX VSL42-08 P42B-08G DK42-08 L42L-08A = Auto Drain (22,32,42 Series only)B = Flexible DrainC = CircleVision Sight BowlE = Endplates (42 Series only)J = External Pulse DrainDimensions: Inches (mm)14 Series:A 7.90 (200) B 5.84 (148) C 6.72 (172) D 3.1 (74)22 Series:A 9.93 (252) B 7.62 (194) C 9.11 (231) D 3.41 (87)32 Series:A 12.32 (313) B 9.12 (232) C 11.25 (286) D 4.10 (104)42 Series:A 17.4 (442) B 12.6 (320) C 16.0 (406) C 5.3 (135)M = Metal Bowls w/ Sight GlassF = Lubricator Quick FillQ = Metal Manual DrainR = Manual Lever Drain!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&425

!"#$%&"'( ®FRLSERIESAir Prep FRL AssembliesAir PrepFlexiblok: StockBlokShut Off/Particulate Filter/Coalescing Filter/Regulator (with Gauge)Model #* To order this )*'+(&"'( model without a shutoffvalve, replace the "V" in the model number with an "X"(ie. M42-08XFFRX).Shut Off/Coalescing Filter-Regulator/Lubricator (with Gauge)* To order this )*'+(&"'( model without a shutoffvalve, replace the "V" in the model number with an "X"(ie. M42-08XFRLX).Shut OffParticulateFilterCoalescingFilterA = Auto Drain (22, 32, 42 Series only)B = Flexible DrainC = CircleVision Sight BowlD = 3 Micron Internal PrefilterE = Endplates (42 Series only)RegulatorM14-01VFFRX VS14-01 F14B-01 F14D-01 R14R-01GM14-02VFFRX VS14-02 F14B-02 F14D-02 R14R-02GM22-02VFFRX VS22-02 F22B-02 F22D-02 R22R-02GM22-03VFFRX VS22-03 F22B-03 F22D-03 R22R-03GM22-04VFFRX VS22-04 F22B-04 F22D-04 R22R-04GM32-04VFFRX VS32-04 F32B-04 F32D-04 R32R-04GM32-06VFFRX VS32-06 F32B-06 F32D-06 R32R-06GM42-06VFFRX VSL42-06 F42B-06 F42D-06 R42R-06GM42-08VFFRX VSL42-08 F42B-08 F42D-08 R42R-08GModel #A = Auto Drain (22,32,42 Series only)B = Flexible DrainC = CircleVision Sight BowlE = Endplates (42 Series only)Shut OffCoalescingFilter-RegulatorLubricatorM14-01VCLXX VS14-01 C14D-01G L14L-01M14-02VCLXX VS14-02 C14D-02G L14L-02M22-02VCLXX VS22-02 C22D-02G L22L-02M22-03VCLXX VS22-03 C22D-03G L22L-03M22-04VCLXX VS22-04 C22D-04G L22L-04M32-04VCLXX VS32-04 C32D-04G L32L-04M32-06VCLXX VS32-06 C32D-06G L32L-06M42-06VCLXX VSL42-06 C42D-06G L42L-06M42-08VCLXX VSL42-08 C42D-08G L42L-08Dimensions: Inches (mm)14 Series:A 7.90 (200) B 5.84 (148) C 6.72 (172) D 3.1 (79)22 Series:A 10.02 (255) B 7.62 (194) C 9.30 (237) D 3.42 (87)32 Series:A 12.32 (313) B 9.12 (232) C 11.25 (286) D 4.10 (104)42 Series:A 17.4 (442) B 12.6 (320) C 16.0 (406) D 5.3 (135)J = External Pulse DrainM = Metal Bowls w/ Sight GlassQ = Metal Manual DrainR = Manual Lever DrainDimensions: Inches (mm)14 Series:A 7.90 (200) B 5.84 (148) C 5.04 (129) D 3.1 (79)22 Series:A 7.93 (252) B 7.62 (194) C 6.95 (177) D 3.42 (87)32 Series:A 12.32 (313) B 9.12 (232) C 8.25 (210) D 4.10 (103)42 Series:A 17.4 (442) B 12.6 (320) C 12.0 (305) D 3.5 (135)J = External Pulse DrainM = Metal Bowls w/ Sight GlassF = Lubricator Quick FillQ = Metal Manual DrainR = Manual Lever DrainShut Off/Particulate Filter/Regulator/Diverter Block/Lubricator (with Gauge)26Model #* To order this )*'+(&"'( model without a shutoff valve,replace the "V" in the model number with an "X" (ie.M42-08XFRLX).Shut OffParticulateFilterRegulatorDiverterBlockA = Auto Drain (22, 32, 42 Series only)B = Flexible DrainC = CircleVision Sight BowlD = 3 Micron Internal PrefilterE = Endplates (42 Series only)LubricatorM14-01VFRDL VS14-01 F14B-01 R14R-01G DK14-02 L14L-01M14-02VFRDL VS14-02 F14B-02 R14R-02G DK14-02 L14L-02M22-02VFRDL VS22-02 F22B-02 R22R-02G DK22-03 L22L-02M22-03VFRDL VS22-03 F22B-03 R22R-03G DK22-03 L22L-03M22-04VFRDL VS22-04 F22B-04 R22R-04G DK22-03 L22L-04M32-04VFRDL VS32-04 F32B-04 R32R-04G DK32-04 L32L-04M32-06VFRDL VS32-06 F32B-06 R32R-06G DK32-04 L32L-06M42-06VFRDL VSL42-06 F42B-06 R42R-06G DK42-06 L42L-06M42-08VFRDL VSL42-08 F42B-08 R42R-08G DK42-08 L42L-08Dimensions: Inches (mm)14 Series:A 7.90 (200) B 5.84 (148) C 8.4 (215) D 3.1 (79)22 Series:A 10.02 (255) B 7.62 (193) C 11.50 (292) D 3.42 (87)32 SeriesA 12.32 (313) B 9.12 (232) C 14.25 (362) D 4.10 (103)42 Series:A 17.4 (442) B 12.6 (320) C 20.0 (508) D 3.5 (135)J = External Pulse DrainM = Metal Bowls w/ Sight GlassF = Lubricator Quick FillQ = Metal Manual DrainR = Manual Lever Drain!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Air Prep FRL Assemblies!"#$%&"'( ®FRLSERIESShut Off/Particulate Filter/Diverter Block/Coalescing Filter-Regulator (with Gauge)Model #* To order this )*'+(&"'( model without a shutoffvalve, replace the "V" in the model number with an "X"(ie. M42-08XFDCX).Shut OffParticulateFilterDiverterBlockA = Auto Drain (22,32,42 Series only)B = Flexible DrainC = CircleVision Sight BowlE = Endplates (42 Series only)F = Lubricator Quick Fill (42 Series only)CoalescingFilter-RegulatorM14-01VFDCX VS14-01 F14B-01 DK14-02 C14D-01GM14-02VFDCX VS14-02 F14B-02 DK14-02 C14D-02GM22-02VFDCX VS22-02 F22B-02 DK22-03 C22D-02GM22-03VFDCX VS22-03 F22B-03 DK22-03 C22D-03GM22-04VFDCX VS22-04 F22B-04 DK22-03 C22D-04GM32-04VFDCX VS32-04 F32B-04 DK32-04 C32D-04GM32-06VFDCX VS32-06 F32B-06 DK32-04 C32D-06GM42-06VFDCX VSL42-06 F42B-06 DK42-06 C42D-06GM42-08VFDCX VSL42-08 F42B-08 DK42-08 C42D-08GShut Off/Particulate Filter-Regulator/Lubricator (with Gauge)Model #Shut OffParticulateFilter-RegulatorLubricatorM14-01VPLXX VS14-01 P14B-01G L14L-01M14-02VPLXX VS14-02 P14B-02G L14L-02M22-02VPLXX VS22-02 P22B-02G L22L-02M22-03VPLXX VS22-03 P22B-03G L22L-03M22-04VPLXX VS22-04 P22B-04G L22L-04M32-04VPLXX VS32-04 P32B-04G L32L-04M32-06VPLXX VS32-06 P32B-06G L32L-06M42-06VPLXX VSL42-06 P42B-06G L42L-06M42-08VPLXX VSL42-08 P42B-08G L42L-08Dimensions: Inches (mm)14 Series:A 7.90 (200) B 5.84 (148) C 6.72 (172) D 3.1 (79)22 Series:A 9.93 (252) B 7.61 (193) C 9.11 (231) D 3.42 (87)32 Series:A 12.32 (313) B 9.12 (232) C 11.25 (286) D 4.10 (104)42 Series:A 17.4 (442) B 12.6 (320) C 6.3 (135) D 16.0 (406)J = External Pulse DrainM = Metal Bowls w/ Sight GlassQ = Metal Manual DrainR = Manual Lever DrainDimensions: Inches (mm)14 Series:A 7.90 (200) B 5.84 (148) C 5.04 (129) D 3.1 (79)22 Series:A 7.93 (252) B 7.62 (194) C 6.95 (177) D 3.42 (87)32 Series:A 12.32 (313) B 9.12 (232) C 8.25 (210) D 4.10 (103)42 Series:A 17.4 (442) B 12.6 (320) C 5.3 (135) D 12.0 (305)Air PrepFlexiblok: StockBlok* To order this )*'+(&"'( model without a shutoffvalve, replace the "V" in the model number with an "X"(ie. M42-08XPLXX).A = Auto Drain (22, 32, 42 Series only)B = Flexible DrainC = CircleVision Sight BowlE = Endplates (42 Series only)J = External Pulse DrainM = Metal Bowls w/ Sight GlasF = Lubricator Quick FillQ = Metal Manual DrainR = Manual Lever DrainShut Off/Particulate Filter/Diverter Block/Regulator/Lubricator (with Gauge)Model #Shut OffParticulateFilterDiverterBlockRegulatorLubricatorM14-01VFDRL VS14-01 F14B-01 DK14-02 R14R-01G L14L-01M14-02VFDRL VS14-02 F14B-02 DK14-02 R14R-02G L14L-02M22-02VFDRL VS22-02 F22B-02 DK22-03 R22R-02G L22L-02M22-03VFDRL VS22-03 F22B-03 DK22-03 R22R-03G L22L-03M22-04VFDRL VS22-04 F22B-04 DK22-03 R22R-04G L22L-04M32-04VFDRL VS32-04 F32B-04 DK32-04 R32R-04G L32L-04M32-06VFDRL VS32-06 F32B-06 DK32-04 R32R-06G L32L-06M42-06VFDRL VSL42-06 F42B-06 DK42-06 R42R-06G L42L-06M42-08VFDRL VSL42-08 F42B-08 DK42-08 R42R-08G L42L-08Dimensions: Inches (mm)14 Series:A 7.90 (200) B 5.84 (148) C 8.4 (215) D 3.1 (79)22 Series:A 10.02 (255) B 7.62 (194) C 11.50 (292) D 3.42 (87)32 Series:A 12.32 (313) B 9.12 (232) C 14.25 (362) D 4.10 (104)42 Series:A 17.4 (442) B 12.6 (320) C 5.3 (135) D 20.0 (508)* To order this )*'+(&"'( model without a shutoffvalve, replace the "V" in the model number with an "X"(ie. M42-08XFDRL).A = Auto Drain (22, 32, 42 Series only)B = Flexible DrainC = CircleVision Sight BowlE = Endplates (42 Series only)J = External Pulse DrainM = Metal Bowls w/ Sight GlasF = Lubricator Quick FillQ = Metal Manual DrainR = Manual Lever Drain!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&427

!"#$%&"'( ®FRLSERIESAir Prep FRL AssembliesAir PrepFlexiblok: StockBlokShut Off/Particulate Filter/Coalescing Filter-Regulator (with Gauge)Model #* To order this )*'+(&"'( model without a shutoffvalve, replace the "V" in the model number with an "X"(ie. M42-08XFCXX).Shut OffParticulateFilterCoalescing/RegulatorM14-01VFCXX VS14-01 F14B-01 C14D-01GM14-02VFCXX VS14-02 F14B-02 C14D-02GM22-02VFCXX VS22-02 F22B-02 C22D-02GM22-03VFCXX VS22-03 F22B-03 C22D-03GM22-04VFCXX VS22-04 F22B-04 C22D-04GM32-04VFCXX VS32-04 F32B-04 C32D-04GM32-06VFCXX VS32-06 F32B-06 C32D-06GM42-06VFCXX VSL42-06 F42B-06 C42D-06GM42-08VFCXX VSL42-08 F42B-08 C42D-08GA = Auto Drain (22,32,42 Series only)B = Flexible DrainC = CircleVision Sight BowlE = Endplates (42 Series only)Dimensions: Inches (mm)14 Series:A 7.90 (200) B 5.84 (148) C 5.04 (129) D 3.1 (79)22 Series:A 9.93 (252) B 7.62 (193) C 6.95 (177) D 3.42 (87)32 Series:A 12.32 (313) B 9.12 (232) C 8.25 (210) D 4.10 (104)42 Series:17.4 (442) B 12.6 (320) C 5.3 (135) D 12.0 (305)J = External Pulse DrainM = Metal Bowls w/ Sight GlassQ = Metal Manual DrainR = Manual Lever Drain28!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Air Prep FRL Assemblies!"#$%&"'( ®FRLSERIES,'-.&"'( /Combination modelsMOD22-08Station Position Description Model Number1 Shut-Off Valve VS22-032 Particulate Filter F22B-033 Coalescer w/ metal bowl <strong>and</strong> pulse drain F22D-03JM4 Diverter Block DK22-034T Regulator R22R-034B Pressure Switch PS180CAN025 Regulator w/ gauge R22R-03G6 Lubricator L22L-03NEED MORE PARTS AND INFORMATION? See page 24 for more information on available drain options.About ,'-.&"'( AssembliesThe !"#$%&"'( ® modular system is designed to connectindividual components into a complete assembly. Sometimes it isnecessary to order an assembly using additional or non-st<strong>and</strong>ardcomponents or combinations. The ,'-.&"'( system makesit easy to order non-st<strong>and</strong>ard combinations.As with all other components <strong>and</strong> combinations, all modularassemblies come factory tested <strong>and</strong> approved <strong>and</strong> assembledcomplete. For more information on flow, dimensions, options, <strong>and</strong>accessories, see individual component pages.Because of the many possible combinations when utilizingmodular systems, it is recommended that complex stationsinclude a schematic drawing. When ordering, specify allcomponents at each station, based on the example to the left.How to label diverter blocksWhen using a diverter block, indicate all units at that stationbefore continuing. If additional units are mounted above thediverter block, use the letter ‘T’ (for ‘top’) as well as a lettersequence (TA, TB, TC, etc.) starting from the diverter block, <strong>and</strong>continuing out. If units are placed below the diverter block, beginthe two letter alphabetic sequence with the letter ‘B’ (for bottom)as well as a letter sequence (BA, BB, BC, etc.) starting with thediverter block <strong>and</strong> continuing outward. Continue in this patternuntil all units are placed correctly.Reducing BushingsReducing bushings may be required to connect somecomponents (i.e. pressure switches, etc.).SeriesSize22 3/8 to 1/4 or 3/8 to 1/832 1/2 to 1/4 or 1/2 to 1/842 Not necessary as diverter block has 1/4 indicator ports.Air PrepFlexiblok: ModuBlok - L1 <strong>and</strong> L2 AdaptersL1 AND L2 Series Air Prep to Valve AdapterHow to OrderModel NumberL1A22L2A22L1A32L2A32DescriptionApplicationThe <strong>Numatics</strong> L1 <strong>and</strong> L2 Series Valve Adapters, whenused with a coalescing regulator (‘piggyback’) equippedwith a pleated prefilter coalescing element <strong>and</strong> thespecified valve, provides a low-cost, complete controlpackage. This design eliminates fittings <strong>and</strong> potential airleaks - thus reducing cost, space, <strong>and</strong> installation time.Features Modular adaptable to 22 or 32 Series !"#$%&"'( ®products. Easy installation <strong>and</strong> service.L1 Series valve adapter for use with 22 Series air preparation productsL2 Series valve adapter for use with 22 Series air preparation productsL1 Series valve adapter for use with 32 Series air preparation productsL2 Series valve adapter for use with 32 Series air preparation productsDimensions: Inches (mm)Series A B C D E!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4L1A22L2A22L1A32L2A322.5(64)3(76)3(76)3(76)1.25(32)1.5(38)1.5(38)1.5(38)2(51)2(51)3(76)3(76)1(25)1(52)1.5(38)1.5(38).75(19).75(19).75(19).75(19)29

!"#$%&"'( ®FRLSERIESNotesAir PrepFor replacement elements <strong>and</strong> other spare parts please refer to page 145.Flexiblok: ModuBlok30

12 SeriesMiniature <strong>FRLs</strong>Air Prep12 Series: Miniature <strong>FRLs</strong>Table of ContentsFeatures <strong>and</strong> Benefits 32Particulate Filter 33Coalescing Filter 34Regulator 35Particulate Filter/Regulator 36Coalescing Filter/Regulator 37Lubricator 38Shut-Off Valve 39Diverter Block 39Reference Additional Information 40

12SERIESMiniature FRL Series12 Series: Miniature <strong>FRLs</strong>Air Prep Low Cost Lightweight Low Profile OEM Modification Available 1/8 or 1/4 NPT, G, or R Threads Diverter Block Available Compact Size Black Anodized Aluminum Heads Can Be Installed as Modular or Individual Variety of Bowls <strong>and</strong> Drains Shut-Off Available32!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&4

Miniature Particulate Filter12SERIESF12B SeriesPrimary air filters are designed to separate liquid, water, rust, pipe scale, <strong>and</strong> debrisfrom air lines. They should be installed upstream of the regulator <strong>and</strong>/or lubricator toprevent contamination from reaching other components.ANSI SYMBOLAir PrepWater is removed mechanically by the deflector which causes the air to move in aswirling motion. The condensed water droplets are then centrifugally impoundedupon the ID of the bowl then fall down past the quiet zone baffle to the water sump.Dry air passes through the sintered element utilizing depth filtration <strong>and</strong> removesdebris down to specified micron size.Features 5 micron sintered elements st<strong>and</strong>ard Can be installed as modular or individual unit Includes screws <strong>and</strong> o-rings for modular connection Polycarbonate bowl st<strong>and</strong>ardSpecificationsBowlPolycarbonateBowlMetal BowlTemperature Range ºF (ºC) 40-120 (4-50) 40-120 (4-50)Dimensions: Inches (mm)F12B-02 pictured12 Series: Particulate FilterMax. Pressure PSIG (BAR) 150 (10) 200 (14)Weight lbs. (kg) 0.22 (0.10) 0.25 (0.11)Flow Ratespressure dropair flow (SCFM)How to OrderF 12 B - 01 JM_ _ModelF = FilterSeries12 = 1.5 oz BowlElementB = 5 Micron ElementThreads- = NPTFG = G Tap (BSPP)R = PT (BSPT)OptionsB = Flexible DrainJ = External Pulse DrainM = Metal BowlQ = Metal Manual DrainR = Manual Lever DrainPort Size01 = 1/802 = 1/4!"#$%&'()$"*+,-./0(*($*01'"2/*3)(1$,(*"$()0/4*5$%*$%6/%)"2*)"#$%&'()$"*$%*%/2'%6)"2*7$,%*8$0'8*+'8/+*$##)0/*9)+)(*3334",&'()0+40$&433