TRANSDEV CATALOGUE 2018 MARCH.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

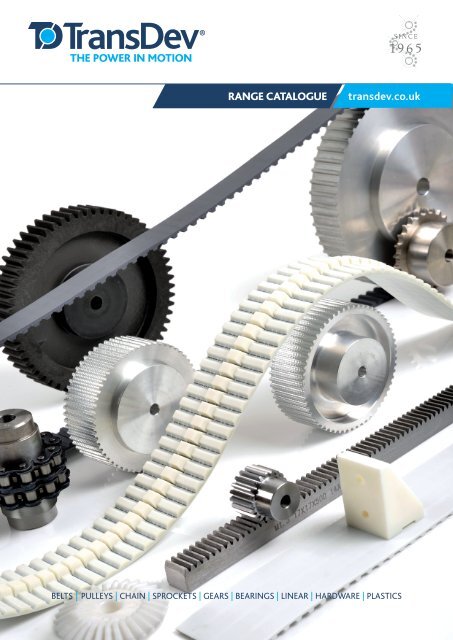

RANGE <strong>CATALOGUE</strong><br />

transdev.co.uk<br />

BELTS | PULLEYS | CHAIN | SPROCKETS | GEARS | BEARINGS | LINEAR | HARDWARE | PLASTICS

Dear Customer<br />

RANGE <strong>CATALOGUE</strong><br />

Ever since Transmission Developments started life over fifty years ago as a specialist manufacturer of<br />

timing pulleys, we have strived to set the highest of standards in power transmission. In the early days<br />

the company’s founder Mr. Stuart Osborne introduced the, then all new, polyurethane metric pitch<br />

“SYNCHROFLEX® Timing Belt” to a British industry that still worked in imperial measurements!<br />

The complete drive concept was the foundation of a company that has grown into the largest<br />

independent, family owned, manufacturer and supplier of transmission belting and related<br />

products in the UK. Continuing the work of Mr. Osborne, Mrs. Jean Osborne drove new investment<br />

and oversaw a restructuring of the company. Her vision enabled new product areas such as<br />

plastics and chain and the development of the company as a major distribution hub.<br />

Today, thanks to the determination of our founders and a solid financial base, we remain focused<br />

on quality, service and our thousands of global customers. I welcome your feedback and<br />

thank you for your business.<br />

Chris Cowler<br />

Managing Director<br />

Belts<br />

Pulleys<br />

Gears<br />

Plastics<br />

Chain<br />

Sprockets<br />

Hardware<br />

Using this catalogue<br />

Every part of this catalogue has been designed to enable easy navigation to the required<br />

product(s). For more information on the icons, terminology and code building see our guide.<br />

7<br />

2

Belts (PU/Rubber/Other) 11<br />

POLYURETHANE<br />

Introduction...................................... 12<br />

Design Program & Measurement Tools...... 22<br />

AT Series........................................... 25<br />

T Series............................................ 45<br />

BRECObasic®..................................... 62<br />

BRECOprotect®.................................. 68<br />

BRECOFLEXmove®.............................. 73<br />

Imperial Series.................................... 75<br />

CONTI® SYNCHRODRIVE &<br />

SYNCHROCHAIN............................... 88<br />

BRECO® Self Tracking..........................100<br />

BRECO® ATN Series............................131<br />

Extra Wide Series...............................141<br />

BRECO® & BRECOFLEX® Flat Belts.........145<br />

Profiled, Special &<br />

Mechanically Reworked Belts................154<br />

Special Belt Backings...........................162<br />

TransDev Drawdown Belts....................169<br />

RUBBER<br />

Introduction.................................... 174<br />

HTD Rubber Series............................ 175<br />

CONTI® CXP & CXA Series.................. 190<br />

Imperial Rubber Series........................ 195<br />

CONTI® SilentSync........................... 212<br />

Vee Belts........................................ 215<br />

Lawn & Garden Belts......................... 231<br />

Poly Vee Drive Belts........................... 239<br />

Rubber Flat Belts.............................. 245<br />

OTHER<br />

Volta Series Friction Belts.................... 250<br />

FERROPAN® Friction Belts................... 262<br />

Esband Belting................................. 266<br />

Pulleys 273<br />

Introduction.....................................274<br />

AT Series Timing Pulleys ......................278<br />

T Series Timing Pulleys ........................292<br />

HTD Timing Pulleys - Pilot Bore..............306<br />

HTD Timing Pulleys - Taper Bore.............324<br />

CONTI® SYNCHROCHAIN & POLYCHAIN<br />

Series Timing Pulleys...........................337<br />

Imperial Series Timing Pulleys -<br />

Pilot Bore and Bar Stock.......................350<br />

Imperial Series Timing Pulleys -<br />

Taper Bore........................................372<br />

Clamp and Tension Plates.....................383<br />

Vee Pulleys.......................................389<br />

Poly Vee Pulleys.................................436<br />

Contents<br />

Chains 443<br />

Introduction.....................................444<br />

Wippermann....................................446<br />

TYC................................................494<br />

Witra..............................................538<br />

D.I.D...............................................561<br />

Sprockets 567<br />

British Standard Sprockets....................570<br />

American Standard Sprockets................596<br />

British Standard Platewheels.................603<br />

Chain Torque Limiters..........................617<br />

Weld on Hubs...................................618<br />

Gears 619<br />

Introduction.....................................620<br />

Metric Spur Gears..............................621<br />

Imperial Spur Gears............................668<br />

Metric and Imperial Racks.....................677<br />

Helical Racks and Pinions.....................689<br />

Metric and Imperial Mitre Gears.............691<br />

Imperial and Metric Bevel Gears.............704<br />

Worm and Wormwheels......................715<br />

Hardware 721<br />

Introduction.....................................722<br />

Bushes............................................723<br />

Couplings ........................................743<br />

Shaft Collars.....................................754<br />

Bearing Housings...............................759<br />

Universal Joints.................................766<br />

Trapezoidal Screws.............................776<br />

RESATEC® .......................................791<br />

Plastics 823<br />

Introduction.....................................824<br />

Plastic Guide Rails..............................825<br />

Semi Finished Engineering Plastics..........841<br />

Display Plastics..................................847<br />

Plastics Overview...............................855<br />

Reference and Index 877<br />

Terms & Conditions of Sale 882<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk transdev.co.uk 3

Power Transmission, Conveying<br />

and Plastics Solutions since 1965<br />

Founded over 50 years ago, TransDev are major manufacturers<br />

and stockists of major timing and conveyor belt and chain<br />

brands; with in-house customisation available.<br />

We are the UK’s largest manufacturer of Pulleys, Gears and Sprockets.<br />

Large gear, pulley and sprocket stocks for rapid rework and<br />

made-to-order are our speciality. We are also a ‘one stop shop’<br />

for Plastic materials, machining, routing and injection moulding.<br />

FIRST<br />

UK Manufacturer of<br />

Special Timing Pulleys<br />

FIRST<br />

Jointed Timing Belts in UK<br />

FIRST<br />

to introduce Polyurethane<br />

Timing Belts to the UK<br />

Committed to innovation<br />

Apart from developing the largest<br />

range of standard and special<br />

transmission, indexing and positioning<br />

belting products, Transmission<br />

Developments has successfully<br />

incorporated an extensive range of<br />

gears, chains and plastics products.<br />

We believe that the off the shelf<br />

availability of all standard products,<br />

backed by our manufacturing of<br />

BRITISH<br />

based in Poole, Dorset<br />

1000+ trade &<br />

distribution customers<br />

£<br />

8M+<br />

turnover<br />

specials, coupled with highly-trained<br />

competent staff is the key to customer<br />

loyalty. Notwithstanding of course, the<br />

importance of representing some of the<br />

most vital brands in the industry, such as<br />

SYNCHROFLEX®, BRECO®, BRECOFLEX®,<br />

CONTITECH®, VOLTA®, WIPPERMANN®,<br />

TYC®, PERSPEX® and more.<br />

50 YEARS<br />

of expertise<br />

3000+<br />

global customers<br />

55,000 SQ FT<br />

production/warehouse space<br />

Quality & Commitment<br />

At TransDev we realise that Quality runs through the entire business, not just our products.<br />

We have continually invested in the right people to provide superior market knowledge<br />

and customer service. Our supply chain partners, from manufacturers to logistics and<br />

information technology are carefully chosen to fit our commitment to Quality.<br />

Quality key facts<br />

In-process and full final inspection<br />

•<br />

Automated Kardex machines deliver<br />

99% picking accuracy levels<br />

• 99.9% of Special Belt orders<br />

completed to specification<br />

•<br />

99.7% of Special Manufacturing<br />

orders completed to specification<br />

TransDev has made quality products since 1965.<br />

This is now backed up by our ISO 9001: 2008 certification.<br />

Certificates of Conformity are also available on request.<br />

For further information please contact our<br />

Quality Assurance Team on +44 (0)1202 675 555<br />

or email quality@transdev.co.uk<br />

4

Trusted Brands<br />

TransDev is a member of Mulco and the UK distributor of the market leading BRECO®,<br />

BRECOFLEX®, CONTI® SYNCHROFLEX® and SYNCHROCHAIN® belting brands.<br />

BRECO®, BRECOFLEX®, CONTI® SYNCHROFLEX® and SYNCHROCHAIN® polyurethane timing<br />

belts are high performance brand products of excellent quality and have a long operating life.<br />

The range offers an extensive selection of profile types, belt widths and lengths.<br />

These are joined by our carefully chosen brands across belting, chain, gears, hardware and<br />

plastics; which include Volta, Wippermann, TYC, Resatec and Perspex to name a few!<br />

Other Belts<br />

THE POWER OF A WELL-MESHED GROUP<br />

Mulco Group<br />

Established as an international Working<br />

Group in 1951, Mulco-Europe EWIV has<br />

evolved today into the leading European<br />

group of manufacturers and sales<br />

companies in the field<br />

of polyurethane timing<br />

belt technology.<br />

Traceability<br />

Goods Labelling<br />

Packaging<br />

Many products are batch traceable and can<br />

be supplied in accordance with REACH, RoHs<br />

and WEEE. Full material certification is also<br />

available on many items upon request.<br />

Goods can be clearly labelled with<br />

customer part and order numbers.<br />

Please ask your TransDev sales<br />

contact for information and costs.<br />

We have an excellent reputation for<br />

the quality of our packaging and the<br />

accurate fulfilment of kitted products.<br />

5

ange catalogue<br />

transdev.co.uk<br />

BELTS | PULLEYS | CHAIN | SPROCKETS | GEARS | HARDWARE | PLASTICS<br />

How to Order<br />

TransDev has one of the largest selections of power transmission<br />

products in the UK. You can currently browse our website<br />

and catalogues and order via the phone, fax or email.<br />

For Special Belts and Manufactured products we<br />

can produce drawings and help you with your<br />

specification, before confirming final costs.<br />

• Stock orders taken before<br />

4.30pm despatched<br />

the same day<br />

•<br />

Integrated MRP system<br />

enables seamless<br />

and fast ordering<br />

•<br />

•<br />

96% of all calls answered<br />

within 20 seconds<br />

98% in-stock ratio<br />

•<br />

Specialist Departments:<br />

TransDev Chain Sales<br />

T +44(0)1202 644 808 F +44(0)1202 644 819<br />

TransDev Plastics<br />

Special Belts & Manufacturing<br />

Over 70% of stock held<br />

in automatic storage<br />

and retrieval machines<br />

• 1600m2 of static racking<br />

• Over 29,000 separate<br />

products held in stock<br />

• Over £3m of stock held<br />

TransDev<br />

T +44(0)1202 670 567 F +44(0)1202 667 768<br />

T +44(0)1202 644 800 F +44(0)1202 644 809<br />

Order now on<br />

0845 0 675 555<br />

Lines open Mon-Fri 9am-5pm,<br />

excluding UK Public Holidays.<br />

Alternatively order via phone, fax or email:<br />

T +44(0)1202 675 555 (non-UK)<br />

F +44(0)1202 677 466<br />

E sales@transdev.co.uk<br />

Delivery<br />

(UK only)<br />

Next Day Express Delivery is available on all standard lines.<br />

Order in stock, standard components before 4.30pm for next<br />

day delivery to UK mainland locations (wherever possible).<br />

Special Belts also enjoy excellent on-time delivery performance:<br />

• Next day delivery possible<br />

on jointed belts ordered<br />

as late as 4:30pm<br />

• Profiled, Wide and Backed<br />

belts normal lead-time<br />

from 1-2 weeks<br />

•<br />

•<br />

•<br />

Backed belts typical lead<br />

time from 5-7 days<br />

Breakdown express cell<br />

delivery from 24 hours<br />

Rework of standard<br />

products from 3-5 days<br />

TAB CUT AREA<br />

To order more copies<br />

of our catalogue or for<br />

general enquiries:<br />

Call +44(0)1202 675 555<br />

or visit transdev.co.uk<br />

Returns<br />

Returns for parts no longer<br />

required will only be accepted<br />

by prior agreement and in<br />

a saleable condition. Please<br />

contact your internal Sales<br />

contact before returning items.<br />

For returns of such parts the<br />

following handling charge applies:<br />

Stock Items<br />

Stock items will be subject<br />

to a 20% handling charge.<br />

Non Stock Items<br />

Non stock items and special<br />

orders are non-returnable and are<br />

unable to be accepted for credit.<br />

For Trade and Distributors<br />

www.transdevdirect.co.uk<br />

Direct is your first port of call for<br />

standard products, including plastics.<br />

Browse our website or contact us direct to enquire<br />

on products, pricing and to place orders.<br />

6

Catalogue Guide<br />

The unique product codes that are used in this catalogue can be used in lieu of a product description when ordering.<br />

If you are not confident you have the correct product code then please liaise with our expert internal Sales contacts,<br />

who will be happy to help. Within the catalogue categories there are pages that explain the codes and how they are built.<br />

Product Codes<br />

SYNCHROCHAIN®<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

CONTI® SYNCHROCHAIN Order Examples<br />

Page Guide<br />

SYNCHROCHAIN®<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

CONTI® SYNCHROCHAIN CARBON<br />

94 344<br />

Product group<br />

Product type<br />

Other Belts<br />

CONTI® SYNCHROCHAIN CTD belt code.<br />

1280 C8M 36<br />

Length in mm<br />

Toothform & pitch<br />

Overall width mm<br />

SYNCHROCHAIN® CARBON Designed for high dynamic stressing up to 40 m/s.<br />

Standard<br />

The CONTI® SYNCHROCHAIN CARBON<br />

delivers up to 30% higher power output<br />

than its predecessor, It therefore opens<br />

up entirely new options to both designers<br />

and users. Its strength can be used in every<br />

mechanical and plant engineering field.<br />

This applies equally to original equipment<br />

14.0<br />

for drives and the aftermarket.<br />

CTD C14M<br />

6.1<br />

10.0<br />

Product icons<br />

Product name<br />

CONTI® SYNCHROCHAIN Carbon CTD belt code.<br />

2100 C14M 90 Carbon<br />

Length in mm<br />

Toothform & pitch<br />

Overall width mm<br />

Resistance to external influences<br />

Highly resistant to various chemicals and oils<br />

Resistant against UV and ozone<br />

• Tropicalized<br />

Temperature resistant from -40°C to 80°C<br />

CTD<br />

C14M<br />

Length & designation<br />

No. teeth<br />

Brand<br />

Cord option<br />

Width<br />

Toothforms<br />

Cord options<br />

See table on next page relating to standard widths.<br />

Available 8M,14M<br />

Aramid<br />

Carbon<br />

Standard widths<br />

20mm<br />

37mm<br />

68mm<br />

90mm<br />

125mm<br />

Permissible peripheral force for<br />

dynamic applications<br />

SYNCHROCHAIN® CARBON<br />

CTD 14M<br />

Width<br />

Fu zul<br />

(mm)<br />

(N)<br />

37 9750<br />

68 18100<br />

90 24500<br />

125 33600<br />

Permissible peripheral force<br />

for quasi-static** applications<br />

where n < 100rpm<br />

SYNCHROCHAIN® CARBON<br />

CTD 14M<br />

Width<br />

Fu zul<br />

(mm)<br />

(N)<br />

37 13200<br />

68 21950<br />

90 31750<br />

125 44000<br />

** A quasi-static application is defined as one where the drive speed is less than 100rpm. The belt<br />

load can possibly be up to 30% higher. In such cases, please contact our technical staff.<br />

994 - C14M 71<br />

1120 - C14M 80<br />

1190 - C14M 85<br />

1260 - C14M 90<br />

1400 - C14M 100<br />

1568 - C14M 112<br />

1610 - C14M 115<br />

1750 - C14M 125<br />

1890 - C14M 135<br />

1960 - C14M 140<br />

2100 - C14M 150<br />

2240 - C14M 160<br />

2310 - C14M 165<br />

2380 - C14M 170<br />

2450 - C14M 175<br />

2520 - C14M 180<br />

2590 - C14M 185<br />

2660 - C14M 190<br />

2800 - C14M 200<br />

3136 - C14M 224<br />

3304 - C14M 236<br />

3360 - C14M 240<br />

3500 - C14M 250<br />

3850 - C14M 275<br />

3920 - C14M 280<br />

4326 - C14M 309<br />

4410 - C14M 315<br />

Essential info,<br />

toothforms<br />

and/or types<br />

Sizing &<br />

availability<br />

94<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

99<br />

Guide to Icons<br />

Every part of this catalogue has been designed<br />

to enable easy navigation to the required<br />

product(s). The Product Category tabs, Main<br />

Contents Index and Category contents listings<br />

are just one way to navigate.<br />

We have also inserted adverts and a set<br />

of icons that indicate compatible products<br />

e.g. Pulleys for Belts, breakdown support and<br />

Customisable Parts.<br />

SYNCHROCHAIN®<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

SYNCHROCHAIN® CARBON Designed for high dynamic stressing up to 40 m/s<br />

Standard<br />

14,0<br />

6,1<br />

10,0<br />

CONTI SYNCHROCHAIN® CARBON<br />

The CONTI SYNCHROCHAIN® CARBON delivers up to 30%<br />

higher power output than its predecessor, It therefore opens<br />

up entirely new options to both designers and users. Its<br />

strength can be used in every mechanical and plant engineering<br />

field. This applies equally to original equipment for<br />

drives and the aftermarket.<br />

CTD C14M<br />

Category icons<br />

Categories are divided by colour and by icon<br />

- these colours also relate to the tabbing<br />

system and any product highlights.<br />

Belts<br />

Pulleys<br />

Chain<br />

Sprockets<br />

Gears<br />

Hardware<br />

Plastics<br />

Resistance to external influences<br />

• Highly resistant to various chemicals and oils<br />

• Resistant against UV and ozon<br />

• Tropicalized<br />

• Temperature resistant from -40C to 80C<br />

Standard widths<br />

20 mm<br />

37 mm<br />

68 mm<br />

90 mm<br />

125 mm<br />

Permissiable peripheral force<br />

for dynamic applications<br />

SYNCHROCHAIN CARBON<br />

CTD 14M<br />

Width Fu zul<br />

[mm]<br />

[N]<br />

37 9750<br />

68 18100<br />

90 24500<br />

125 33600<br />

** A quasi-static application is defined as one where the drive speed is less than 100 rpm. The belt load can possibly be up to 30% higher. In such<br />

cases, please contact our technical staff.<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

299<br />

Permissiable peripheral force<br />

for quasi-static**<br />

applications where n < 100 rpm<br />

SYNCHROCHAIN CARBON<br />

CTD 14M<br />

Width Fu zul<br />

[mm]<br />

[N]<br />

37 13200<br />

68 21950<br />

90 31750<br />

125 44000<br />

CTD C14M<br />

Product icons<br />

Length & Designation Number of teeth<br />

994 - C14M 71<br />

1120 - C14M 80<br />

1190 - C14M 85<br />

1260 - C14M 90<br />

1400 - C14M 100<br />

1568 - C14M 112<br />

1610 - C14M 115<br />

1750 - C14M 125<br />

1890 - C14M 135<br />

1960 - C14M 140<br />

2100 - C14M 150<br />

2240 - C14M 160<br />

2310 - C14M 165<br />

2380 - C14M 170<br />

2450 - C14M 175<br />

2520 - C14M 180<br />

2590 - C14M 185<br />

2660 - C14M 190<br />

2800 - C14M 200<br />

3136 - C14M 224<br />

3304 - C14M 236<br />

3360 - C14M 240<br />

3500 - C14M 250<br />

3850 - C14M 275<br />

3920 - C14M 280<br />

4326 - C14M 309<br />

4410 - C14M 315<br />

Our product icons helps you quickly find details<br />

and complementary products.<br />

106<br />

24hr Breakdown available<br />

Customisable product<br />

Product code builder<br />

transdev.co.uk<br />

Compatible product<br />

e.g. Matching pulley (page no)<br />

76<br />

7

State of the art equipment has<br />

enabled TransDev to manufacture<br />

some of the most complex<br />

belts ever made, many within<br />

microns of pitch accuracy.<br />

Special Belts<br />

TransDev has a dedicated sales team with exceptional product knowledge<br />

across Standard and Special Belts. Fast quotations are provided for<br />

Standard and Special Belts (jointed, open, backed etc.), including over the<br />

phone. Most Special Belts are quoted within 1 hour and our competitive<br />

pricing reflects our status as a manufacturer as well as supplier.<br />

TransDev have the largest Special Belt machining capabilities in the UK.<br />

We utilise CNC machinery to grind, slit, punch and slot belts and can<br />

also manufacture, fit and grind standard or specially made profiles of any<br />

shape up to 800mm in width. Our specialist machines can weld tooth belts<br />

up to 460mm in width and are among the fastest in our industry.<br />

• We have the capacity to produce over<br />

2,500 Jointed Belts each month<br />

35,000 metres of belting in stock<br />

Jointed Belts available from stock<br />

• FDA and JFS food quality materials<br />

One of the largest stock profiles in Europe<br />

Wide Belts available up to 460mm in width<br />

Transback<br />

TransDev typically<br />

produces over 600 backed<br />

belts each month, with 26<br />

different backing materials<br />

available, all from stock.<br />

• Special backings are<br />

available to suit all<br />

applications<br />

• Vulcanized backings (no joint)<br />

available on belts up to 3 metres<br />

in length<br />

• CNC grinding, grooving and slitting<br />

of belts up to 120 metres in length<br />

• Bonded materials are available to<br />

suit many applications<br />

High friction, low friction, soft, hard or compressible backings<br />

• Experts in Haul-off belts for the packaging,<br />

plastic and cable industries<br />

• All belt backings can be specially machined/ground to drawing<br />

Autoclaved Belts<br />

TransDev continuously backed timing belts<br />

ensure that there is no join to fail. If you need a<br />

backed belt that can run in either direction, with<br />

a backing that is an integral part of the belt, then<br />

you need a TransDev Autoclaved Timing Belt.<br />

10 special types of rubber held in stock<br />

• New materials can be developed to<br />

suit your special requirements<br />

•<br />

All the popular Haul-down belts and<br />

Sausage Belts are available from stock<br />

Kitting<br />

TransDev’s parts kitting service is used to<br />

supply complex, multi-level kits of parts to<br />

our customers. Computer controlled systems<br />

ensure all components and assemblies involved<br />

in a kit are purchased and kitted together.<br />

Our service ensures the kits are produced correctly<br />

and in accordance with the customer’s specification<br />

at every stage of the process, which is quality<br />

controlled to ensure 100% conformance.<br />

8

Special Manufacturing<br />

TransDev is the UK’s largest timing pulley manufacturer<br />

with a capacity from 4mm to 1 metre in diameter.<br />

We utilise manual and CNC machining, operating<br />

two manned and one unmanned shift per day.<br />

• 17,000 pulleys, gears and<br />

sprockets manufactured<br />

per month (average)<br />

• Dedicated manufacturing<br />

sales team with<br />

exceptional product<br />

knowledge<br />

• Fast quotations, with<br />

most items to drawing<br />

quoted within 1 hour<br />

• World Class MRP system,<br />

with barcode tracking<br />

that enables us instant<br />

access to the live<br />

status of your order<br />

• Live work queues<br />

enable us to make<br />

real time changes to<br />

assist your delivery<br />

requirements on existing<br />

orders in production<br />

The<br />

• Over £300,000 of<br />

tooling covering all<br />

SYNCHOFLEX®; BRECO®;<br />

SYNCHROCHAIN®;<br />

HTD®, Imperial;<br />

Polychain®; Eagle®;<br />

Clamp Plates; Gears<br />

& Sprockets pitches<br />

• Competitive pricing<br />

Plastics<br />

TransDev Plastics is the dedicated Plastics Division<br />

of Transmission Developments Co (GB) Ltd.<br />

Our plastics division was created approximately<br />

25 years ago to machine components from sheet<br />

UHMWPe and is now a major supplier nationwide of<br />

such items as chain and belt guides, bespoke machined<br />

parts as well as engineering and display plastics.<br />

With our experience of plastics stocking, distribution<br />

and our reputation for good service, you can depend on<br />

TransDev Plastics. Our expert telephone sales staff are able<br />

to give assistance on materials machining and handling.<br />

TransDev also have a specialist engineering section<br />

for milling and routing anything from one offs to large<br />

batches. Should you require a finished product, please<br />

enquire for a competitive quotation and service. We also<br />

offer an injection moulding service, Transmould.<br />

TransDev Plastics Division has four areas of operation:<br />

• Transplas machined stock shapes, covering primarily<br />

Polyethylene Wear Strip materials and a vast range of<br />

extruded profiles<br />

• Engineering plastic stock range, covering<br />

semi-finished rod and sheet materials<br />

Display plastic stock range, including Perspex acrylic sheets<br />

• Transmould injection moulding service<br />

Other Belts<br />

Technical Support<br />

Need Help? TransDev has a team of technical experts<br />

in all aspects of drive design technology waiting to<br />

help. TransDev can also run training sessions to help our<br />

customer’s design engineers and to educate on the latest<br />

power transmission practices and new developments.<br />

T +44(0)1202 675 555<br />

F +44(0)1202 677 466<br />

E technical@transdev.co.uk<br />

Breakdowns<br />

TransDev can offer a 24 hour service on stock products and<br />

can immediately manufacture and dispatch made-to-order<br />

products in a machine breakdown situation.<br />

To use this premium service, please contact the<br />

duty manager (English only spoken) on:<br />

T 44 (0)7850 548 351<br />

We regret this number cannot be used for progressing<br />

orders out of hours. (UK and Europe only)<br />

24/7<br />

365<br />

For downloads and information visit:<br />

transdev.co.uk/knowledgebase<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

9

THE KING OF POWER<br />

AND PERFORMANCE<br />

BRECO® is the leader in polyurethane timing belt solutions.<br />

BRECO® are the most innovative producer in the field of polyurethane<br />

timing belt technology worldwide. Their high-quality and reliable<br />

products feature wear resistant polyurethane for the belt body and<br />

high tensile steel cord tension members.<br />

The BRECO® and BRECOFLEX® timing belts, the pulleys and other<br />

matching components reflect the experience gathered over decades of<br />

successful and reliable usage.<br />

• Innovation<br />

• Strength<br />

• Performance<br />

• Trust<br />

BRECO® Keeps You Moving<br />

For BRECO see page 15<br />

10

SEARCH<br />

BACK TO MAIN CONTENTS<br />

Polyurethane Belts<br />

Introduction. .....................................12<br />

CONTI® Synchroflex. ............................................ 13<br />

BRECO® and BRECOFLEX®. .................................. 15<br />

Design Program & Measurement Tools. .............................. 22<br />

AT Series. .........................................25<br />

AT3. ......................................................... 28<br />

AT5. ......................................................... 30<br />

AT10, ATL10. ................................................... 33<br />

ATP10, ATP15, ATS15. ............................................ 36<br />

AT20, ATL20. ................................................... 41<br />

T Series. ..........................................45<br />

K1.5, T2, T2.5. .................................................. 48<br />

T5 . .......................................................... 52<br />

T10. ......................................................... 55<br />

T20. ......................................................... 58<br />

BRECObasic®. .....................................62<br />

BRECOprotect®. ..................................68<br />

BRECOFLEXmove®. ................................73<br />

Imperial Series. ...................................75<br />

MXL. ......................................................... 78<br />

T1/5” (XL). .................................................... 79<br />

T3/8” (L). ..................................................... 81<br />

T1/2” (H). ..................................................... 83<br />

T7/8” (XH). .................................................... 85<br />

CONTI® SYNCHRODRIVE & SYNCHROCHAIN. .......88<br />

SYNCHRODRIVE. ............................................... 89<br />

SYNCHROCHAIN. ............................................... 93<br />

SYNCROCHAIN CARBON. ........................................ 97<br />

BRECO® Self Tracking. ........................... 100<br />

ATK5, ATK10, ATK20. ........................................... 105<br />

TK5, TK10, TK1/2”. ............................................. 111<br />

BAT10, BATK10, BAT15, BATK15. ................................. 118<br />

SFAT10, SFAT15, SFAT20. ....................................... 126<br />

BRECO® ATN Series. ............................. 131<br />

Extra Wide Series. ............................... 141<br />

BRECO® & BRECOFLEX® Flat Belts. ............... 145<br />

Profiled, Special & Mechanically Reworked Belts. ... 154<br />

Welded-on Profiles. ............................................ 155<br />

Belt Connecting Systems. ........................................ 160<br />

Special Belt Backings. ........................... 162<br />

TransDev Drawdown Belts. ...................... 169<br />

Other Belts<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

11

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

Polyurethane Belts<br />

The manufacturing process used for TransDev<br />

timing belts produces close tolerance timing<br />

belts, which ensure the even distribution of load<br />

during use and will allow the transmission of high<br />

torques. Due to the high accuracy of these drives,<br />

they are also suitable for indexing, positioning<br />

and conveying drives.<br />

Synchronous running and low elongation, coupled<br />

with maintenance-free operation makes the<br />

TransDev timing belt range the ideal means of<br />

power transmission.<br />

Timing pulleys can be supplied in conjunction<br />

with TransDev timing belts as complete drives.<br />

As well as a popular stock range, TransDev can<br />

manufacture special pulleys to drawing in all pitches<br />

and profiles. Standard material for timing pulleys is<br />

free-machining aluminium alloy (6082-T6). Other<br />

materials such as Steel, Stainless Steel, Cast Iron<br />

and various plastics are also available.<br />

Application areas<br />

TransDev timing belts are suitable for use in all<br />

industries where the synchronous transmission<br />

of angular motion is required. They are therefore<br />

suitable for all types of power transmission,<br />

indexing, positioning and conveying, eg:<br />

Office machinery<br />

Data processing machinery<br />

Food processing machinery<br />

Textile machinery<br />

Woodworking machinery<br />

• Machine tools<br />

TransDev offers five types of polyurethane timing belt:<br />

Properties<br />

Reduced noise<br />

Extremely wear resistant<br />

Efficiencies up to 98%<br />

Maintenance-free<br />

Belt speed up to 80 m/sec<br />

• Chemically stable<br />

Resistant to fats and petrol<br />

Extremely oil resistant<br />

Hydrolysis resistant<br />

Large power range<br />

Low initial tension<br />

•<br />

Slipless, synchronous operation<br />

Constant length, no post elongation<br />

Temperature ranges available from -25°C to<br />

+110°C (dependent on special PU's)<br />

Chemically resistant to ozone and sunlight<br />

Conditionally resistant to acids and alkalis<br />

High positional and angular accuracy<br />

Can be welded to other thermoplastics<br />

Low mass, suitable for positioning and stepper motor drives<br />

SYNCHROFLEX ®<br />

GEN III ®<br />

BRECOFLEX ®<br />

BRECO ® M<br />

BRECO ® V<br />

12

SEARCH<br />

BACK TO MAIN CONTENTS<br />

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

SYNCHROFLEX® Products and Performance<br />

K1.5/MP/T2/T2.5<br />

T2.5 dimensions<br />

shown<br />

Profile Types<br />

Power range<br />

RPM Speed<br />

0-0.5 kW<br />

0-20000rpm<br />

0-80 m/s<br />

Camera drives<br />

Control drives<br />

Precision drives<br />

Other Belts<br />

T5<br />

0-5 kW<br />

0-10000rpm<br />

0-80 m/s<br />

Office equipment<br />

Kitchen equipment<br />

Tacho drives<br />

Machine tools<br />

T10<br />

0-30 kW<br />

0-10000rpm<br />

0-60 m/s<br />

Printing machinery<br />

Primary and auxiliary drives<br />

Machine tools<br />

T20<br />

0-100 kW<br />

0-6500rpm<br />

0-40 m/s<br />

Heavy construction drives<br />

Compressors<br />

Paper machinery<br />

AT3<br />

0-5 kW<br />

0-20000rpm<br />

0-80 m/s<br />

Office equipment<br />

Handling equipment<br />

Computer equipment<br />

AT5<br />

0-15kW<br />

0-10000rpm<br />

0-80 m/s<br />

Machine tools<br />

Pumps<br />

Textile machinery<br />

AT10<br />

2,5<br />

0-70 kW<br />

0-10000rpm<br />

0-60 m/s<br />

Textile machinery<br />

Paper machinery<br />

Roll table drives<br />

ATP10<br />

2,5<br />

0-100 kW<br />

0-10000rpm<br />

0-60 m/s<br />

Construction machinery<br />

Pumps<br />

Compressors<br />

ATP15<br />

15<br />

3.75<br />

2.85<br />

0-250 kW<br />

0-10000rpm<br />

0-50 m/s<br />

Construction machinery<br />

Pumps<br />

Compressors<br />

AT20<br />

4<br />

0-250 kW<br />

0-6500rpm<br />

0-40 m/s<br />

Heavy textile machinery<br />

Printing plant<br />

Machine tools<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

13

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

Brand Introduction<br />

ContiTech<br />

ContiTech is a leading specialist for rubber and plastics<br />

technology. They develop and produce functional parts,<br />

components and systems for the automotive and other<br />

important industries.<br />

Their guiding principle is 'Engineering Next Level'.<br />

As a driver and inspiration for new, cutting-edge technologies<br />

and an expert in materials and processes, ContiTech remain<br />

circumspect and considered as they take things to the Next<br />

Level – in every respect.<br />

They keep a close eye on changes and trends in society and<br />

technology so that they can adapt appropriately to provide<br />

market-focused solutions for the benefit of their customers<br />

and of people around the world. They are an innovation<br />

leader in natural rubber and plastic products and have a<br />

wealth of expertise in materials and processes, which they<br />

have gathered over the decades. They are quick to offer<br />

markets the solutions they need – whilst always aiming for<br />

the top in quality.<br />

SYNCHROFLEX® Timing Belts<br />

The SYNCHROFLEX® range of belts consists of only two components; a wear<br />

resistant Contilan carcass and high grade endless steel wire tension members.<br />

The excellent bond between the two results in a high flank load capacity,<br />

combined with low elastic elongation, making them unsurpassed for quality<br />

and accuracy. The manufacturing process produces close tolerance timing<br />

belts, to ensure optimum mesh in all power ranges. SYNCHROFLEX® belts<br />

comply with DIN 7721 and have proved themselves in operation for more<br />

than 50 years.<br />

SYNCHROFLEX® timing belts are manufactured in a mould in pre-defined<br />

lengths. TransDev hold a large stock of all sizes of SYNCHROFLEX ® timing<br />

belts, ready for immediate despatch.<br />

SYNCHROFLEX® GEN III Timing Belts<br />

Each generation is different. GEN III is better! The combination of high<br />

tensile steel cord tension members and wear resistant polyurethane forms<br />

the basis for dimensionally stable and extremely durable high performance<br />

timing belts.<br />

GEN III further develops the power drives of the AT and ATP range CONTI®<br />

SYNCHROFLEX polyurethane timing belts. The new GEN III generation excels<br />

with a 25% increase in power transmission compared with the AT/ATP standard.<br />

In addition it delivers added value for money, with all CONTI® SYNCHROFLEX<br />

GEN III polyurethane timing belts supporting the use of standard AT/ATP<br />

pulleys. A bifilar tension member arrangement and a higher packing density<br />

enables this high-performance polyurethane belt to yield greatly improved<br />

benchmark results compared with the standard AT and ATP range. The increased<br />

strength allows line engineers to utilise a larger number of load-carrying teeth.<br />

14<br />

24hr Breakdown available Customisable product XX Product code builder XX Compatible product

SEARCH<br />

BACK TO MAIN CONTENTS<br />

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

Brand Introduction<br />

Driven by innovation is the principle that marks out BRECO® Antriebstechnik Breher GmbH & Co., manufacturer of BRECO® and<br />

BRECOFLEX® timing belts. They are the most innovative producer in the field of polyurethane timing belt technology worldwide.<br />

The basis for a high-quality and reliable product is provided by wear resistant polyurethane for the belt body and high tensile steel<br />

cord tension members.<br />

The name BRECO® has become the synonym for polyurethane timing belts, as a result of years of experience in the field of<br />

thermoplastic polyurethane, the development of BRECO® and BRECOFLEX® manufacturing processes and their further development.<br />

The BRECO® and BRECOFLEX® timing belts, the pulleys designed to match them perfectly and other components supplied by<br />

BRECO® reflect the breadth of experience gathered over decades by countless people who have used the products.<br />

Other Belts<br />

BRECOFLEX ®<br />

Endless polyurethane belts are ideal for all power transmission<br />

applications where non-standard belt lengths are required. Pairs<br />

of helically wound, continuous Steel tension members mean<br />

that BRECOFLEX® timing belts do not feature a join of any kind.<br />

BRECOFLEX® timing belts use an innovative production technique<br />

allowing the extruded belt to be manufactured to almost any truly<br />

endless belt size. Although there is a standard range of BRECOFLEX®<br />

belts, their true strength is in their ability to be manufactured to<br />

a specific required length and to special order. Small minimum<br />

quantities may apply depending on the length and width required,<br />

without detriment to delivery time.<br />

BRECO ® M<br />

Open ended polyurethane timing belts are used extensively for linear drives,<br />

replacing more expensive mechanical alternatives.<br />

The extruded lengths comprise a wear resistant polyurethane toothform encasing<br />

parallel high strength steel tension cords. The reels are extruded in lengths of<br />

50m or 100m, although special lengths and matched pairs can be made to<br />

order. Shorter lengths can be cut to order from these reels, although<br />

minimum quantities may apply depending on the length and<br />

width required.<br />

BRECO ® V<br />

Joined timing belts are the ultimate in timing belt versatility. These<br />

joined belts are manufactured from lengths of BRECO® M and can<br />

be used for conveying and indexing applications where long centre<br />

distances or non-standard lengths are required on a fast delivery<br />

schedule. A wide range of welded profiles and belt backings can be<br />

applied to BRECO® V belts to transform them into highly specialised<br />

products. BRECO® M are cropped with interlocking fingers at each<br />

end, then joined in a heat welder to provide any length of timing belt,<br />

subject to minimum length required to wrap the belt around a heat<br />

welding jig. Minimum quantities may apply depending on the length<br />

and width required.<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

15

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

BRECO® Products and Performance<br />

AT3<br />

ATS15<br />

Power transmission<br />

≤ 5 kW<br />

Power transmission<br />

≤ 160 kW<br />

Rotational speed Approx. 20.000 min -1<br />

Peripheral speed Approx. 80 ms -1<br />

Synchronous pulley From z=15<br />

Rotational speed Approx. 8.000 min -1<br />

Peripheral speed Approx. 48 ms -1<br />

Synchronous pulley From z=25<br />

Application examples<br />

Small power drives,<br />

Handling technology<br />

Application examples<br />

Power drives, paper-making machines,<br />

high-bay storage, lifting equipment<br />

AT5<br />

BAT15, BATK15<br />

Power transmission<br />

≤ 15 kW<br />

Power transmission<br />

≤ 140 kW<br />

Rotational speed Approx. 10.000 min -1<br />

Peripheral speed Approx. 80 ms -1<br />

Synchronous pulley From z=15<br />

Rotational speed Approx. 8.000 min -1<br />

Peripheral speed Approx. 48 ms -1<br />

Synchronous pulley From z=20<br />

Application examples<br />

Machine tools, pumps,<br />

textile machinery<br />

Application examples<br />

Power drives, pumps,<br />

grinding machine<br />

AT10, BAT10, BATK10, SFAT10, ATK10K6<br />

ATP10<br />

Power transmission<br />

≤ 70 kW<br />

Power transmission<br />

≤ 100 kW<br />

Rotational speed Approx. 10.000 min -1<br />

Peripheral speed Approx. 60 ms -1<br />

Synchronous pulley From z=15<br />

Rotational speed Approx. 10.000 min -1<br />

Peripheral speed Approx. 60 ms -1<br />

Synchronous pulley From z=15<br />

Application examples<br />

Construction machines, pumps,<br />

paper-making machines, compressors,<br />

textile machines, roller-table drives<br />

Application examples<br />

Sanding machinery, power<br />

drives, machine tools<br />

16

SEARCH<br />

BACK TO MAIN CONTENTS<br />

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

BRECO® Products and Performance<br />

SFAT15<br />

Power transmission<br />

≤ 135 kW<br />

Rotational speed Approx. 8.000 min -1<br />

Peripheral speed Approx. 48 ms -1<br />

Synchronous pulley From z=20<br />

ATP15<br />

Power transmission<br />

Possible beyond 200 kW<br />

Rotational speed Approx. 10.000 min -1<br />

Peripheral speed Approx. 50 ms -1<br />

Synchronous pulley From z=20<br />

Other Belts<br />

Application examples<br />

Construction machines, pumps,<br />

paper-making machines, compressors<br />

Application examples<br />

Power drives, machine tools<br />

AT20, SFAT20<br />

T10, L, H<br />

Power transmission<br />

Possible beyond 200 kW<br />

Power transmission<br />

≤ 30 kW<br />

Rotational speed Approx. 6.500 min -1<br />

Peripheral speed Approx. 40 ms -1<br />

Synchronous pulley From z=18<br />

Rotational speed Approx. 10.000 min -1<br />

Peripheral speed Approx. 60 ms -1<br />

Synchronous pulley From z=12<br />

Application examples<br />

Heavy-duty drives, textile machinery,<br />

printing machinery, machine tools<br />

Application examples<br />

Machine tools, main and<br />

subsidiary drives, textile<br />

machines, printing machinery<br />

T5, XL<br />

T20, XH<br />

Power transmission<br />

≤ 5 kW<br />

Power transmission<br />

Up to approx. 100 kW<br />

Rotational speed Approx. 10.000 min -1<br />

Peripheral speed Approx. 80 ms -1<br />

Synchronous pulley From z=10<br />

Rotational speed Approx. 6.500 min -1<br />

Peripheral speed Approx. 40 ms -1<br />

Synchronous pulley From z=15<br />

Application examples<br />

Office machinery,<br />

do-It-yourself units, positioning<br />

and regulating drives<br />

Application examples<br />

Heavy construction machinery,<br />

paper machinery, pumps,<br />

compressors, textile machinery<br />

Note: Special timing belt designs allow the RPM and peripheral speed parameters to be increased.<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

17

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

BRECO® Available Versions<br />

Standard Version, single-sided<br />

Standard Version, double-sided<br />

Standard Version<br />

The standard version of the BRECO® and BRECOFLEX®<br />

timing belt is a combined construction of two<br />

materials: wear resistant polyurethane and high tensile<br />

steel cord tension members. The Standard Version is<br />

universally applicable for all tasks in drive and<br />

conveying technology.<br />

• Ordering code not required<br />

Version DL<br />

The Standard Version of the double-sided BRECO® and<br />

BRECOFLEX® timing belts is a combined construction<br />

of two materials: wear resistant polyurethane and high<br />

tensile steel cord tension members. Full loadability on<br />

both tooth sides. The Standard Version of the DL timing<br />

belts are universally applicable for all tasks in drive and<br />

conveying technology.<br />

• Ordering code: DL<br />

Standard version with reinforced belt back<br />

Standard version with transport coating<br />

Version DR<br />

The DR version is the same as the Standard Version<br />

The<br />

however with a thicker belt back.<br />

• Ordering code: version DR<br />

Version T<br />

T version is the same as the Standard Version<br />

with the exception of a transport coating thickness of<br />

1.5mm (T5) and 2mm (T10, T20, AT10 AT20, Imperial<br />

timing belts), which is extruded on the belt back. The<br />

timing belt in T version is universally applicable for all<br />

tasks in conveying technology.<br />

• Ordering code: version T<br />

18

SEARCH<br />

BACK TO MAIN CONTENTS<br />

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

BRECO® Available Versions<br />

Nylon tooth facing<br />

Nylon facing on the back of the belt<br />

Other Belts<br />

Version PAZ<br />

Version PAR<br />

The belt base corresponds to the Standard Version.<br />

The<br />

An additional nylon tooth facing causes a lower friction<br />

coefficient, lightens the tooth mesh in the pulley and<br />

reduces noise. Transport belts on bed plates run easier<br />

and are wear resistant.<br />

• Ordering code: PAZ<br />

belt base corresponds to the Standard Version.<br />

An additional nylon tooth facing causes a lower<br />

friction coefficient. Application area in the conveying<br />

technology: e.g. for accumulation conveyor (back of<br />

the belt runs easier and is wear resistant).<br />

Ordering code: PAR<br />

• Ordering code: PAZ-PAR (both sides coated)<br />

Nylon facing on double-sided belts<br />

Version DL-PAZ<br />

The belt base corresponds to the double-sided<br />

Standard Version. An additional nylon tooth facing<br />

causes a lower friction coefficient, lightens the tooth<br />

mesh in the pulley and reduces noise. Transport belts<br />

on bed plates run easier and are wear resistant.<br />

•<br />

Ordering code: DL-PAZ<br />

(coating only possible on inner side)<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

19

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

BRECO® Available Materials<br />

Materials for standard application areas<br />

Material Selectable tension member Timing belt types Colour Hardness Temperature range<br />

TPUST1<br />

Steel cord<br />

Stainless Steel cord<br />

All standard types, not for<br />

BRECOFLEX® belts up to 720mm<br />

White 92 Shore A 0°C up to +80°C<br />

TPUST2<br />

Steel cord<br />

Stainless Steel cord<br />

All standard types, not for<br />

BRECOFLEX® belts up to 720mm<br />

Transparent 85 Shore A +5°C up to +50°C<br />

TPUST3<br />

Steel cord<br />

Stainless Steel cord<br />

BRECOFLEX® belts up to 720mm Transparent 92 Shore A 0°C up to +80°C<br />

Approved materials for contact with food<br />

Material Selectable tension member Timing belt types Colour Hardness Temperature range<br />

TPUFD1 Stainless Steel cord All standard types Transparent 92 Shore A 0°C up to +80°C<br />

Materials for use in areas with a low aggressive environment<br />

Material Selectable tension member Timing belt types Colour Hardness Temperature range<br />

TPUAU1<br />

Stainless Steel cord<br />

All standard types, not for<br />

BRECOFLEX® belts up to 720mm<br />

Transparent 92 Shore A 0°C up to +50°C<br />

Materials for use in areas with high ambient temperature<br />

Material Selectable tension member Timing belt types Colour Hardness Temperature range<br />

TPUWB1<br />

Steel cord<br />

Stainless Steel cord<br />

All standard types, not for<br />

BRECOFLEX® belts up to 720mm<br />

White<br />

94 Shore A<br />

+20°C up to<br />

+110°C<br />

Materials for use in areas with low ambient temperature<br />

Material Selectable tension member Timing belt types Colour Hardness Temperature range<br />

TPUKF1<br />

Steel cord<br />

Stainless Steel cord<br />

All standard types, not for<br />

BRECOFLEX® belts up to 720mm<br />

Transparent 85 Shore A -25°C up to +5°C<br />

Materials with electrical discharge properties<br />

Material Selectable tension member Timing belt types Colour Hardness Temperature range<br />

TPUAS1<br />

Steel cord<br />

Stainless Steel cord<br />

All standard types, not for<br />

BRECOFLEX® belts up to 720mm<br />

Grey-transparent 92 Shore A 0°C up to +80°C<br />

For further information about the resistance of polyurethane timing belts and available belt materials<br />

as well as alternative tension member materials please contact our sales department.<br />

20

SEARCH<br />

BACK TO MAIN CONTENTS<br />

POLYURETHANE BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

The E Steel cord tension member<br />

Highly flexible tension inserts - the E Steel cord tension member<br />

Other Belts<br />

The thinner the single wire, the more flexible the<br />

overall tension member! This interrelation led BRECO®<br />

to develop BRECO® and BRECOFLEX® timing belts with<br />

E tension members.<br />

In the E tension member the cord cross-section is<br />

distributed to a greater number of thinner individual<br />

wires and, therefore, the bending fatigues are markedly<br />

lower. The major advantage of the E tension members is<br />

higher flexibility.<br />

This is especially important, when smaller mounting<br />

dimensions for pulleys and tension rollers are required.<br />

The minimum number of teeth and/or minimum<br />

diameter of the pulleys can be up to 30% less,<br />

compared with standard tension members.<br />

Timing belts with E tension members are recommended<br />

for multi-shaft drives with frequent bends.<br />

Application information: For intended application under extreme<br />

conditions please contact our Technical Department for advice.<br />

Steel cord tension members (Example):<br />

Standard<br />

tension member<br />

'E' tension<br />

member<br />

The thinner the individual wire the more flexible the whole<br />

timing belt.<br />

Summary<br />

•<br />

Thinner individual wires in the Steel cord<br />

Higher dynamic capabilities<br />

Extremely high bonding and bending fatigue strength<br />

Smaller pulley and tension roller diameter<br />

No correction of the synchronising<br />

pulleys are necessary<br />

Available versions<br />

•<br />

For the pitches AT3 (as standard),<br />

AT5, AT10, ATP10, T5, T10, T20 (option)<br />

Type Drive Value T5 T10 T20 AT3 AT5 AT10 ATP10<br />

Z min<br />

(smooth)<br />

d min<br />

Z min<br />

d min<br />

Pulley zmin<br />

Idler dmin<br />

(mm)<br />

Pulley zmin<br />

Idler dmin<br />

(mm)<br />

10 12 15 15 12 12 12<br />

18 50 80 20 18 50 50<br />

15 15 20 20 20 20 20<br />

18 50 120 20 50 80 80<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

21

DESIGN PROGRAM<br />

For Polyurethane Belt Drives<br />

Mulco Belt Pilot<br />

Mulco Belt Pilot is an interactive online application that<br />

helps you quickly and accurately design and specify<br />

your belting solution. You can determine the number of<br />

teeth, plan the width of belts or calculate the diameter<br />

of timing pulleys.<br />

The calculation results achieved with the Mulco Belt<br />

Pilot are valid for BRECO®, BRECOFLEX® and CONTI®<br />

SYNCHROFLEX, including GEN III, polyurethane timing<br />

belts. Both Rotary and Linear power drive designs are<br />

covered.<br />

Rotary power drive design features<br />

• Provides shaft centre positions when choosing<br />

pulley sizes and preferred belt lengths<br />

• Enables design of two pulley or multi-pulley<br />

'serpentine' drives<br />

•<br />

Provides power and torque capacity of<br />

the chosen belt, at the given RPM<br />

General features<br />

• •<br />

Details safety factors for tensile strength and tooth<br />

shear strength<br />

Provides precise figures for correct belt pretension<br />

Delivers printed results, including graphics of<br />

the data and chosen components<br />

Linear power drive design features<br />

• Provides moving carriage linear slide design,<br />

for reciprocating movement<br />

• Enables design of open and closed vertical linear<br />

drives, with or without counterweights<br />

•<br />

Design for linear trolleys, utilising 'Omega' drive geometry<br />

Gives the linear force capacity of the chosen<br />

belt, at the given linear velocity<br />

Mulco Belt Pilot is available via our web site www.transdev.co.uk and you will need to register the first time you use it.<br />

22

SEARCH<br />

BACK TO MAIN CONTENTS<br />

MEASUREMENT TOOLS<br />

Tension Meter<br />

TSM5 and TSM5-F tension meter<br />

The TSM5 is a pocket size belt tension meter which<br />

measures the static tension of all common toothed, Vee,<br />

flat and multi-rib belts.<br />

Other Belts<br />

Setting the correct static tension (pretension Fpt) influences<br />

the working life, bearing loads, noise levels and positioning<br />

accuracy of the belt.<br />

Specification<br />

•<br />

• CE marked<br />

Frequency range: from 7Hz to 400Hz Accuracy: +/-5%<br />

Supplied with long-life 9V alkaline battery, protective<br />

leatherette case and transport case with instructions<br />

TSM 5<br />

The value Fpt can be determined by calculation where the peripheral force<br />

is known, or empirically where the torque value is unknown. Generally the<br />

ideal pretension level is that which gives least vibration of the unloaded<br />

belt span when in operation.<br />

The tension meter is designed to measure the static tension of a belt, by<br />

determining the natural frequency of vibration of the belt under tension.<br />

Operating instructions<br />

•<br />

• •<br />

On a static drive, gently tap the belt between two<br />

fixed points using a finger or a small screwdriver<br />

Simultaneously hold the sensor head a few millimetres<br />

from the belt and press the red button<br />

The display will show the frequency of vibration in Hertz (H )<br />

To repeat the reading, release the button and repeat the process<br />

It is recommended that several readings are taken to<br />

obtain an average value in order to eliminate possible<br />

errors due to harmonic interference frequencies<br />

TSM 5F<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

23

MEASUREMENT TOOLS<br />

Antistatic Conductivity Meter<br />

Antistatic Conductivity Meter<br />

Polyurethane timing belts can generate substantial static charges<br />

during normal use, which can be dissipated by means of a TransDev<br />

antistatic coating and tested by means of a TransDev Antistatic<br />

Conductivity Meter.<br />

Dielectric materials are by definition poor conductors of electricity.<br />

When such materials are separated after contact with either a<br />

conducting material or another insulating material, a static electric<br />

charge can be produced by the capacitance effect, which can<br />

lead to sparking or crackling. This effect can also occur with belts<br />

which are insulating when they run on metal pulleys. The electric<br />

discharges which result can cause the following problems:<br />

Interference with electronic equipment<br />

Risk of ignition or explosion of flammable materials<br />

•<br />

Risk of shocks to the operator from the high<br />

voltages which can be generated<br />

The British Standard BS2050 (1978) and DIN 22104 are<br />

the recognised specifications which cover the test<br />

procedures and accepted levels for rubber and polyurethane<br />

timing belts relating to antistatic properties. The maximum<br />

surface resistance for BS2050 5x10 x 1 (8*b) Ohms and<br />

for DIN EN 3 x 10 Ohms.<br />

Antistatic Meter details<br />

TransDev is able to supply you with an Antistatic<br />

Conductivity Meter. This pocket sized conductivity meter<br />

measures the conductivity on an antistatic coated belt.<br />

The meter uses correctly spaced contact probes to ‘A.S.T.M.’<br />

standard D-257 for sensing its measurements, with an<br />

accuracy of half decade. It is operated by a 9 volt battery,<br />

providing 40 hours of testing time.<br />

The meter measures surface conductivity by simply placing<br />

the instrument on the surface of the coated belt to be<br />

checked and pressing the green test button. The appropriate<br />

L.E.D. will illuminate from 10 10 Ohms per square. To<br />

measure surface conductivity over an unspecified distance<br />

insert the earth lead into the earth socket. This isolates<br />

the test probe on the right side of the monitor. Attach<br />

the crocodile clip to the antistatic coated belt and place<br />

the monitor on the belt surface at the required position,<br />

press and hold the test button. The L.E.D. that illuminates<br />

constantly indicates the decade measured.<br />

Antistatic coatings<br />

TransDev has developed a post manufacturing<br />

electrically conductive black coating which<br />

complies with the above specifications and<br />

is available on all neoprene rubber timing<br />

belts and 3 different polyurethane substrates<br />

(Breco Desmopan 590, Desmopan 385 and<br />

SYNCHROFLEX®).<br />

Certification is available for all belt types.<br />

The antistatic timing belt is, therefore, a specific<br />

and new solution for all those who operate in<br />

hazardous industrial fields where static build-up<br />

would present potentially disastrous<br />

circumstances (eg chemicals, mining, oil and<br />

electronics). It is obvious that during the working<br />

life of the drive the eventual reduction of<br />

conductivity means that the testing of the belt’s<br />

resistance in a planned maintenance schedule<br />

is important.<br />

24

SEARCH<br />

BACK TO MAIN CONTENTS<br />

AT Series Timing Belts<br />

Other Belts<br />

HIGHER BELT LIFE<br />

OPTIMISED TRACKING<br />

REDUCED NOISE<br />

TEMPERATURE RANGE<br />

INCREASED TO 100°C<br />

RUNS ON STANDARD<br />

AT/ATP TIMING PULLEYS<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

25

AT SERIES TIMING BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

AT Series Timing Belt Order Examples<br />

Four standard types<br />

SYNCHROFLEX® AT truly endless power drive belting from stock.<br />

Width (mm)<br />

Toothform<br />

Tooth pitch (mm)<br />

Belt length (mm)<br />

Abbreviation<br />

(High performance version)<br />

25 AT 10 / 840 SYN (GEN III)<br />

BRECOFLEX® AT truly endless power drive belting made to order.<br />

Width (mm)<br />

Toothform<br />

Tooth pitch (mm)<br />

Belt length (mm)<br />

Abbreviation<br />

32 AT 10 / 2240 BFX + options<br />

BRECO® M AT open length linear drive belting from stock.<br />

Width (mm)<br />

Toothform<br />

Tooth pitch (mm)<br />

Belt length (mm)<br />

Abbreviation<br />

Note:- ATL is a higher strength version using the same pulleys<br />

50 AT 10 / 5.5 BRECO® M + options<br />

BRECO® V AT joined conveyor belting from stock.<br />

100 AT 10 / 12,320 BRECO® V + options<br />

Width (mm)<br />

Toothform<br />

Tooth pitch (mm)<br />

Belt length (mm)<br />

Abbreviation<br />

For other options, double sided, backings, cord types, flighted belts, self tracking, etc.<br />

contact sales@transdev.co.uk<br />

26

SEARCH<br />

BACK TO MAIN CONTENTS<br />

AT SERIES TIMING BELTS<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

Additional Belt Options<br />

Available options in SYNCHROFLEX® truly endless belts<br />

DL<br />

Double sided belt, (for serpentine drives)<br />

E<br />

Flexible steel tension cords, (Smaller pulleys or serpentine drives)<br />

KEV<br />

Aramid tension cords, (Non-magnetic or food use)<br />

GEN III<br />

Higher performance AT Profile belts<br />

Other Belts<br />

9080 Low operating temperature PU -35°C to 80°C (not in all sizes)<br />

Available options in BRECOFLEX® truly endless, BRECO® M Open<br />

length & BRECO® V joined belts.<br />

DL<br />

PAZ<br />

PAR<br />

KEV<br />

ST ST<br />

E<br />

DR<br />

FD1<br />

KF1<br />

Double sided belt, (for serpentine drives)<br />

Low friction green fabric tooth covering, (Quiet running)<br />

Low friction green fabric back covering, (Accumulating conveyor)<br />

Aramid tension cords, (Non-magnetic or food use)<br />

Stainless Steel tension cords, (Food or under water use)<br />

Flexible steel tension cords, (smaller pulleys or serpentine drives)<br />

Thicker Polyurethane (PU) backing, 92 shore A (Wear resistant conveying)<br />

Food or medical grade PU (Use Aramid or Stainless Steel cords)<br />

Low operating temperature PU -25°C to+5°C<br />

WB1 High operating temperature PU +20°C TO 110°C<br />

AS1<br />

UV<br />

T<br />

Antistatic PU<br />

Higher resistance to Ultra Violet (UV) light PU<br />

2mm thick 85 Shore A, PU backing<br />

Other options may be available on request<br />

Some options can be combined; please ask<br />

• Minimum order quantities may apply<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk<br />

27

CONTI SYNCHROFLEX® - AT SERIES<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

AT3 Standard & GEN III SYNCHROFLEX®<br />

26 280<br />

Polyurethane, steel reinforced, cast truly endless - High Power AT Profile in metric pitch with trapezoidal toothform.<br />

Standard<br />

GEN III<br />

AT3<br />

AT3<br />

CONTI SYNCHROFLEX® timing belt AT3<br />

CONTI<br />

Available version:<br />

Single-sided<br />

With E tension member for greater flexibility<br />

With Reinforced design<br />

With Aramid tension member upon request<br />

Polyurethane special materials upon request<br />

• Antistatic, coloured, mechanical reworked<br />

Standard stock lengths (mm)/Number of teeth<br />

SYNCHROFLEX® timing belt AT3 GEN III<br />

Standard version:<br />

Single-sided<br />

High performance polyurethane in red colour<br />

Steel cord tension members with high density<br />

• Steel cord tension members in two filament,<br />

highly flexible construction<br />

• 25% more power than standard AT<br />

Length No. teeth Std. GEN III<br />

150 50 <br />

201 67 <br />

252 84 <br />

267 89 <br />

270 90 <br />

300 100 <br />

351 117 <br />

Length No. teeth Std. GEN III<br />

399 133 <br />

417 139 <br />

450 150 <br />

501 167 <br />

549 183 <br />

600 200 <br />

639 213 <br />

Length No. teeth Std. GEN III<br />

648 216 <br />

714 238 <br />

816 272 <br />

900 300 <br />

1011 337 <br />

Preferred belt width in mm: 6, 10, 16, 25, 32 – Other dimensions on request<br />

Technical Specification<br />

Standard<br />

(belt widths)<br />

Tension member<br />

loadings<br />

b (mm) 6 10 16 25 32<br />

(N) 190 380 646 1102 1406<br />

Belt weight kg/m 0.014 0.023 0.037 0.058 0.074<br />

Drive Type A<br />

Type A AT3 GEN III<br />

Z min 15 15<br />

d min 20 20<br />

Drive Type B<br />

Type B AT3 GEN III<br />

Z min 20 20<br />

d min 20 20<br />

GEN III<br />

(belt widths)<br />

Tension member<br />

loadings<br />

b (mm) 6 10 16 25 32<br />

(N) 330 599 1002 1608 2079<br />

Belt weight kg/m 0.016 0.026 0.042 0.065 0.083<br />

Z min Z min<br />

d min<br />

d min<br />

Z min<br />

= Minimum number of teeth. d min<br />

= Minimum diameter (mm)<br />

28 24hr Breakdown available Customisable product 106 XX<br />

Product code builder 299 XX<br />

Compatible product

SEARCH<br />

BACK TO MAIN CONTENTS<br />

BRECO® - AT SERIES<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

AT3 BRECOFLEX® & BRECO® (M) & (V)<br />

26 280<br />

20%<br />

EXTRA POWER<br />

Polyurethane, steel reinforced - High Power AT Profile in metric pitch with trapezoidal toothform.<br />

Standard<br />

Standard<br />

AT3 BFX<br />

AT3<br />

AT3 BRECOFLEX®<br />

Available versions for AT3:<br />

•<br />

AT3: standard single sided<br />

Special polyurethane upon request<br />

Antistatic, coloured, machined,<br />

ground and punched belts<br />

• Backings<br />

BRECO® Open length (M) & joined (V)<br />

AT3 (M/V)<br />

Available lengths & versions<br />

Standard delivery lengths (M) Rolls of 50 or 100m<br />

Cut to length/lengths > 100m<br />

On request<br />

Minimum length joined (v)<br />

480mm<br />

Standard material TPUST1 1)<br />

Standard tension member -<br />

Belt widths (mm) – Intermediate belt widths on request<br />

6 10 16 25 32<br />

E tension member (standard)<br />

Stainless Steel tension member<br />

x<br />

o<br />

AT 3 – Allowable tensile load<br />

Belt width b (mm) 6 10 16 25 32<br />

Tension<br />

member loadings<br />

F adm (N)<br />

AT 3 - BRECOFLEX® Preferred Lengths (mm)<br />

720 819 918 1017 1116<br />

1215 1314 1413 1512 1611<br />

1710<br />

AT3 BFX<br />

Available lengths & versions<br />

Preferred lengths 720 up to 1710<br />

Minimum purchase amount<br />

Any number of teeth<br />

available from<br />

E tension member (standard)<br />

Stainless Steel tension<br />

PAZ<br />

1 sleeve, 100mm wide<br />

720mm up to 1,710mm<br />

BFX/M 190 380 645 1100 1400<br />

V 90 180 285 500 632<br />

Belt weight kg/m 0.014 0.023 0.037 0.058 0.074<br />

x<br />

o<br />

x<br />

PAZ<br />

DL/DL-PAZ -<br />

T/T-PAZ -<br />

T/T-PAZ -<br />

x Available, minimum purchase amounts may apply<br />

o Minimum purchase amount on request<br />

- Not available<br />

1) Further materials on request<br />

Drive Type A<br />

Type A AT3 (BFX) AT3 (M/V)<br />

Z min 15 15<br />

d min 20 30 (20)<br />

Drive Type B<br />

Type B<br />

AT3 (BFX) AT3 (M/V)<br />

Z min 20 25 (20)<br />

d min 20 30 (20)<br />

Z min<br />

Z min<br />

= Minimum number of teeth. d min<br />

= Minimum diameter (mm)<br />

Values in brackets apply to joined timing belts.<br />

x<br />

d min<br />

d min<br />

Z min<br />

29<br />

T +44 (0)1202 675 555 F +44 (0)1202 677 466 E sales@transdev.co.uk<br />

transdev.co.uk

CONTI SYNCHROFLEX® - AT SERIES<br />

Polyurethane Timing, Conveying and Indexing Belts<br />

AT5 Standard & GEN III SYNCHROFLEX®<br />

26 281<br />

Polyurethane, steel reinforced, cast truly endless - High Power AT Profile in metric pitch with trapezoidal tooth form.<br />

Standard<br />

GEN III<br />

AT5<br />

AT5<br />

CONTI SYNCHROFLEX® timing belt AT5<br />

Available versions:<br />

Single-sided<br />

With E tension member for better flexibility<br />

With reinforced design upon request<br />

With Aramid tension member upon request<br />

Polyurethane special materials upon request<br />

• Antistatic, coloured, mechanical reworked<br />

Length No. teeth Std. GEN III<br />

225 45 <br />

255 51 <br />