Hello and welcome to our very rst issue of Fruit & Vine magazine. It’s with great excitement that we are now able to produce a bespoke magazine for this booming industry, supporting British growers and producers of the nest fruits, juices and wines.

Some of you may know us already, as we produce Farmers Guide, a national monthly farming magazine that’s sent free and direct to 30,000 farmers in the UK. Like most farms, it’s a family business, with the magazine being run by us, Julie and Greg – daughter and grandson of Doug Potts, who started the magazine in 1979.

Just like Farmers Guide, Fruit & Vine is packed full of expert arable, machinery and industry editorial, relevant advertising from our clients and our famous classi ed section. In these pages, our readers can advertise their surplus machinery and equipment for free, printed alongside adverts from the biggest names in the industry.

If you would like to receive this magazine FREE six times a year, then sign up online at www.fruitandvine.co.uk or email us via hello@fruitandvine.co.uk – if you prefer, you can also call the team on 01473 794440.

We love to hear from our readers, so get in touch if you’d like to be featured in a future issue, want to advertise in the pages or have some feedback!

Julie and Greg794440

People & property: The latest industry movers and shakers

Products, research and events you need to know about

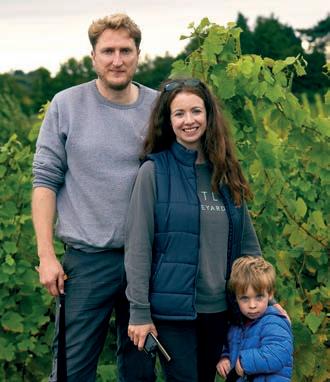

Grower pro le: Su olk vineyard is a small force of nature

Improved grape quality justi es harvester investment

Proven design, new application

Focus on quality and pro tability will follow

Agronomy: Vine Winter vineyard priorities

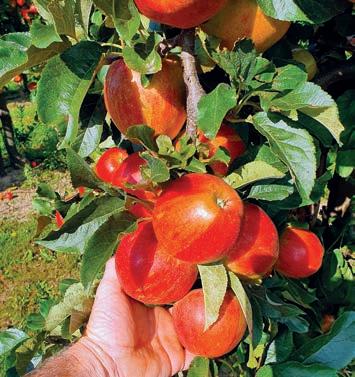

Agronomy: Fruit Extending fruit yields, quality and shelf life

Choose varieties to suit your site and your bank balance, as well as the palate

Variety spotlight: Strawberries Variety choice is crucial

Technical advice: Vineyard trellis is key to success

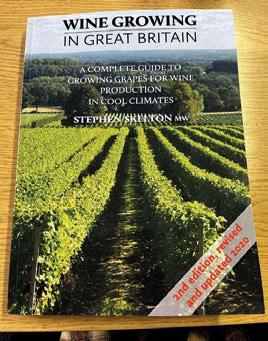

Thinking about investing in a vineyard? ‘Wine’ not?!

Advice from those who have been there and done it

Printed by William Gibbons & Sons LtdFruit & Vine magazine is published by Early Bird Fruit Publications Ltd from its o ce at Parkside, London Road, Ipswich, Suffolk IP2 0SS. Tel: 01473 794440. Full contact details for staff can be found at www.fruitandvine.co.uk.

Original articles and advertisements created by Fruit & Vine are copyright and are not to be reproduced in any form without the written permission of the Editor. No responsibility can be accepted by Fruit & Vine for the opinions expressed by its contributors.

ISSN: 2753-474X

Managing director

Goulding

Goulding greg@fruitandvine.co.uk

Rachel Hicks

Kidby hello@fruitandvine.co.uk

Machinery editor

Williams hello@fruitandvine.co.uk

Staff writer

Szathmary hello@fruitandvine.co.uk

Hors eld chloe@fruitandvine.co.uk

Senior sales executive

Blower hello@fruitandvine.co.uk

Senior sales executive

Moyes hello@fruitandvine.co.uk

Sales executive

Fox hello@fruitandvine.co.uk

Sales executive

Smith hello@fruitandvine.co.uk

executive

Sweet hello@fruitandvine.co.uk

Sales executive

Taylor hello@fruitandvine.co.uk

Classi ed sales manager

Procter hello@fruitandvine.co.uk

Classi ed sales executive

Wilson hello@fruitandvine.co.uk

Assistant studio manager

Smith hello@fruitandvine.co.uk

Being sold by Che ns in Cambridge, the property is situated in Linton, just eight miles south-east of the University City of Cambridge. The sale forms part of the assets of Chilford Hundred Limited to include the 22-acre vineyard, the winery, winemaking equipment and approximately 45,000 bottles of wine produced on the estate.

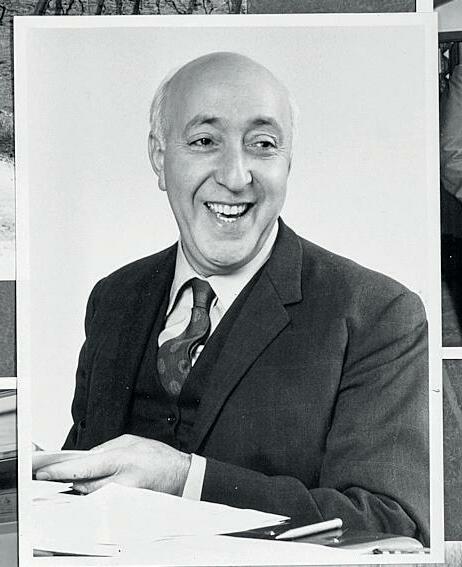

The award-winning vineyard was established in 1972 by the late entrepreneur, Sam Alper OBE (pictured), and now includes nine di erent grape varieties, producing over 18,000 bottles per year of red, white, rosé and sparkling wines. Across the 18-acres of established vines are varieties including Müller-Thurgau, Schönburger, Otega, Reichensteiner, Pinot Noir, Rondo, Regent, Dornfelder and Siegerrebe. Chilford Hall wines have won many awards and accolades for the quality from the United Kingdom Vineyards Association, which is now known as WineGB. The remaining four acres provide scope for further planting or development of the vineyard.

The winery buildings are set around a central grassed courtyard and include a period timberframed building, converted Dutch barn and a bonded cellar which includes white marble pillars from the Long Bar at Waterloo Station. The site extends to approximately six acres and

includes just over two acres of undeveloped land, providing opportunities for further expansion.

Head wine maker, Mark Barnes, who studied viticulture and oenology at Plumpton College, has been with the company for 16 years and consistently produces award-winning wines. Due to increasing demands for the expertise held by Mark and the rising number of growers in East Anglia, Chilford Hundred Limited has invested in all the latest equipment for making quality still and sparkling wines, and undertakes contract wine-making for eight other growers in the region – with three more coming on-stream in the next three or four years. It also provides viticulture consultancy and vine planting services.

Popular vineyard tours and tasting Chilford Hall Vineyard is a popular destination for vineyard tours and tastings, which form an important part of the business. These, at present, take place in a marquee and bistro on land which the seller is retaining, but would be happy to lease to a new owner.

Sam Alper OBE was the designer of the Sprite Caravan and the founder of the Little Chef chain of restaurants. He was also the founder of the East Anglian Wine Growers Association (now WineGB East) and a board member of the United Kingdom Vineyards Association (now WineGB). He was a

shareholder and on the board of the International Wine and Spirit Competition. A great promoter of English wine, he took part in the 1983 Great English Wine Rally, driving samples of his wine to the George V Hotel in Paris in his 1930 vintage Rolls-Royce.

Sam’s widow, Fiona Alper, who is selling the vineyard and winery, says it has been an exciting journey being involved in English wine. “I have met so many interesting people and have wined and dined in the most incredible places, from Napa Valley to Hungary. I now want to retire and feel it is the right time for someone with passion and energy to take the vineyard and winery to the next level.”

Simon Gooderham, joint managing partner at Che ns, which is handling the sale commented:

“This is an exceptional opportunity for a buyer to purchase one of the oldest vineyards in England and to take this already well-regarded business yet further. The inty soils overlying chalk at Chilford Hall are ideal for the production of English sparkling wine, which has been an expanding area of success for the business.

“The English wine market is evolving at pace, and we have seen a growth in interest in this emerging sector within the rural market. Whilst there are now believed to be over 700 vineyards in England and Wales, few of these are as well as established as Chilford Hall, and with its freedraining soil, it has conditions similar to those found in the Champagne region of France, making it perfect for sparkling wine production.”

Chilford Hall vineyard and winery, one of England’s oldest established commercial vineyards, recently hit the open market with a guide price of £2 million

Kingscote Wine Estate is a well-positioned commercial vineyard in the heart of the Sussex Weald, situated between the historic Bluebell Railway and Weir Wood Reservoir

Savills has been instructed to market the Kingscote Estate Vineyard, which can be sold whole or in two lots.

Lot one comprises 60 acres of vines, a fully equipped winery, traditional barn for visitors and events, two-bedroomed holiday cottage, ‘substantial’ additional farm buildings, shing lakes, pasture and woodlands.

All-in-all, it totals around 151 acres, and has a guide price of £4.95M.

Lot two is Mill Place Farmhouse, which has a guide price of £1.8M. This imposing, ve-bedroomed Grade II listed farmhouse with 1.16 acres of gardens and grounds, sits in a prominent position enjoying views across the Kingscote Vineyard.

According to Savills, who are marketing the property, the current owners have worked hard to create a destination and brand that are vital to the success of a modern wine business.

At the heart of the 16-acre site is a visitor centre, completely refurbished in a contemporary style, and associated vineyard buildings. The visitor centre is designed as

popular tourist attraction with retail outlet, tasting bar and bistro, and is an excellent venue for private or corporate events.

Sustainable features include a ground source heat pump, a Bio-Bubble wastewater treatment plant and rainwater harvesting.

Whilst there isn’t currently an

Across the estate about 60 acres of vines have been planted, with varieties including Pinot Meunier, Pinot Noir, Chardonnay, Bacchus, Pinot Blanc and Regent.

The initial vines were planted in 2010, 2011, 2013 and more lately extensive planting in 2018, which will be bearing signi cant fruit from 2021 onwards. The vineyards have been planted on southerly slopes and have been established to produce more than 100,000 bottles of still and sparkling wine per annum.

There is also a two-acre apple orchard which lies to the east of the farmstead and was planted in 2011, the fruit from which has been used in the past and present to produce original method Cyder.

The winery contains all the latest technology for producing premium sparkling and still wine using stainless steel and temperature control. All the stages of wine production from vine to the shop can be undertaken on site.

equipped winery (the wine is made o -site), the open-plan room to the rear of the building is fully set-up with services to accommodate wine making equipment. There are two clay amphoras, popular for the fermentation or ageing of the wine.

Sedlescombe is the oldest organic and biodynamic vineyard in the UK, having been established in 1979. There are currently approaching seven acres under vine – Regent, Solaris, Monarch and Pinot Noir (2.5 acres) planted in 2018. The southernmost eld, around 4.4 acres, is unplanted at present.

Situated beyond the visitor area

Timber-framed under a tiled roof, this magni cently restored barn originates from the 15th century and occupies a prominent position with a courtyard to the front and garden behind with views over the vineyard and towards the Bluebell Railway.

Inside, the barn is open-plan and full of character, with a wealth of exposed original timbers and o ers potential for a variety of uses. The ground oor is home to an impressive kitchen and bar area, with utility room beyond. At one end, a mezzanine gallery overlooks the main entertainment space, which has been used in the past as a smaller meeting area and as a stage for the band at functions. There are ladies, gents and disabled WCs.

The current owners have created a highly popular venue for buyers of wine (and many of the other products on o er), vineyard tourists and locals.

is a south-facing timber framed and timber clad chalet bungalow (subject to an Agricultural Occupancy Condition) constructed in 1987 to low energy use speci cation. It enjoys views over the vineyards and countryside beyond from a timber deck at the rear. The accommodation brie y comprises two reception rooms, a spacious kitchen/dining room, three bedrooms, two bathrooms and two cloakrooms.

The vineyard is also home to 45 ‘dragon’s teeth’, large concrete anti-tank obstacles that were placed on the site at the start of World War II.

Sedlescombe Organic Vineyard in East Sussex is a well-established wine estate with potential for further expansion

David joins Stocks with almost 30 years of experience in the agricultural machinery industry. A native of Northern Ireland, David grew up on a dairy farm and started out as a graduate engineer at the old Massey Ferguson tractor factory in Coventry.

Following AGCO’s acquisition, David worked for the multinational in many areas of the agricultural business – from sales, support and after-market as well as in distribution development across the world, spending ve years at the Massey Ferguson Asia Paci c o ce in Singapore and six years in AGCO’s regional o ce in Melbourne Australia. Most recently David worked for the Fella and former Lely Welger factories as export business development manager.

“David brings a wealth of experience to Stocks,” said managing director James Woolway. “I am con dent he will lead the sales team here in the UK, as well as develop our export business – we are lucky to have him.”

Commenting, David said: “I have come across Stocks Ag products in many parts of the world, from dual wheels in peat applications in Indonesia, to seeders in the far north of Japan, making this an irresistible opportunity. Stocks is well-positioned to build on an excellent reputation and I am excited to be part of the new growth phase both in the UK and the rest of the world.”

Stocks has been manufacturing slug pelleters, applicators and seeders as well as dual, xed and adjustable centre wheels for over 40 years. Alongside a healthy UK market in the agricultural and horticultural sectors, Stocks also supplies OEMs and export customers.

Vinescapes Ltd has announced the appointment of Emma Rice as consultant winemaker. Emma is one of the UK’s most respected winemakers, the company says, with over 16 years of experience and 21 vintages in the UK, California, Tasmania, and New Zealand

In her role as consultant winemaker, Emma will be advising clients on their wine styles and strategy, production planning and equipment sourcing, winery design and winemaking consultancy. Emma’s expertise will drive the company forward as it expands to provide the most comprehensive support for its clients from their early business conceptions, creating and managing their vineyards and wineries through to celebrating their winemaking successes.

In her previous position as head winemaker at Hattingley Valley Wines, Hampshire, Emma was central to the development of the winery as an internationally award-winning wine producer, both for their own brand and their very numerous contract clients. She has a strong background in wine chemistry and analysis, and created the winemaking laboratory Custom Crush at Hattingley Valley Wines – supporting the whole industry with

wine analytical services.

Emma graduated from Plumpton College, East Sussex, in 2006 with a BSc degree in Viticulture & Oenology. In 2014 and 2016 she was awarded UK Winemaker of the Year, achieving the highest points for her wines in the national competition. She has the Wine & Spirit Education Trust diploma, is a liveryman of the Worshipful Company of Vintners, co-author of The UK Wine Growers Handbook, with Dr Belinda Kemp, former editor of Hugh Johnson’s Pocket Wine Book, former WineGB chair of the Winemaking Working Group as well as a renowned international speaker. Emma has an impressive list of prestigious national and international awards for her still and sparkling wines and is considered instrumental in raising the standard and reputation of English Sparkling Wine over the past 15 years.

Emma’s appointment will expand the services o ered by Vinescapes enabling clients to bene t

from a complete 'Ground to Grape to Glass' provision with top quality consultancy, including: • Wine production business consultancy: de ning wine style and winemaking strategy market

• Wine production planning: support with strategic and operational planning and decision making

Advice on winery equipment, utility requirements and other winery infrastructure Winemaking consultancy; from trouble shooting oenological challenges to directing production process.

Following two years of either fully virtual or hybrid events, wine2wine is back for its 9th year. The theme for 2022 is ‘Wine Communication’.

According to the organisers, this encompasses communication/ marketing of wine in all its forms, from traditional – such as PR and press – to the use of social and digital mediums; from developments in education and training to the application of the most innovative new communicative tools. The wine2wine business forum 2022 sessions aim to provide an overview of the main trends and developments in this context, inviting speakers and the public to re ect together on what works and what doesn’t in communicating wine today, within the global viticulture market. Some of the topics and presentations include:

• Strategy – can a wine brand sold in grocery stores ever be a luxury product? Selling wine at major retailers is great for pro t margins, but if you’re sold in the grocery store, can your wines also be sold on the wine lists of top restaurants?

• Market trends – readers don't care about sustainability This talk will explore the topics and trends surrounding wine and beverage that American readers are most interested in right now. The session will concentrate on three main points:

1. Readers are looking for stories that connect them more closely to the beverages they enjoy.

2. Current trends include a focus on stories about underrepresented communities and wines they may be unfamiliar with.

3. Do not assume the only thing readers want to know about though are obscure regions and

wines. There is still great interest in the well known wines and wine regions of the world.

• Marketing – #winetok Why the clock is ticking on one of the world’s greatest marketing tools and how you can cash in.

• Communications – what is wine communication in 2022? In 2002, like wine producers, book publishers and authors largely relied heavily on traditional critics and reviewers.

Today, they also have TikTok, Instagram and peer reviews on Goodreads and Amazon. The #Booktok tag has been used over 39,000,000,000 times. TikTok in uencers are now becoming more important to book publishing than most classic reviewers.

When it comes to social media marketing, wine in China has adopted this shift more rapidly than in the west. Wang Shenghan, aka Lady Penguin, a 33-year-old leading wine in uencer, has built an e-commerce platform with revenues of over $35m. But it is not just in uencers; a Vivino marketing campaign can be more coste ective today than promoting a Wine Spectator score.

Many in the industry are uncomfortable with these trends, but ignoring them may be a mistake. Former award-winning author and critic and now industry analyst, Robert Joseph, also takes a level-headed look at the rapid way wine communication is changing, reveals the ndings from new research, and suggests the ways many producers may need to adapt.

For more information or to book tickets, visit https:// wine2wine.net/

“Over the last six months, since DEFRA con rmed the scrapping of the horticulture and potato levies and a zero-rated levy for 2022, as predicted we have seen the industry begin to take ownership for its own research and development activity, setting its own priorities and ensuring that those who want the research are able to bene t from it,” says Lincolnshire vegetable grower, Peter Thorold.

In the horticultural sector, a number of crop associations have announced plans to either introduce their own crop-speci c research levies or to work together where there are areas of common interest. In the potato sector, growers have come together to create new growerled organisations for the ware and seed sectors, and these initiatives are eligible for tax relief where appropriate.

The industry has also continued to be eligible for targeted R&D funding, such as DEFRA’s Farming Innovation Programme, which has provided funding for projects in fruit production and vegetable harvesting, among others. In the private sector, organisations including Fera Science and NIAB

have also begun to manage collaborative projects on key issues, bringing together stakeholders from numerous backgrounds to work on a common goal.

Lincolnshire potato and vegetable grower John Bratley comments: “We are pleased to see the crop associations taking the initiative with their members to get targeted R&D done without the monolithic approach that was the AHDB. Now, with the extra pressure from increasing input costs that growers face, it is more important than ever that the statutory levies have been removed and growers can now decide what areas of focus are best for their businesses.”

Protected flower grower Simon Redden adds: “Those of us growing niche products, or who don’t use crop protection chemicals, received very little or no benefit from AHDB. The removal of the statutory levy means we are no longer funding our competitors and in the uncertain times ahead we can decide where we need to invest in our companies to get the maximum benefit.

The AHDB petitioners have welcomed the emergence of a new self-regulating R&D environment following the formal lifting of compulsory levies on the potato and horticulture sectors

One UK biostimulant brand has enjoyed a record-breaking rst half of the year, reporting a 33% increase in year-on-year sales in the rst six months of 2022

MJP Supplies, which distributes Algifol in the UK, sold more than 3,000 litres of the seaweed-based biostimulant between 1st January and 1st July.

“The rising cost of fertilisers, the hot weather and extremely low rainfall have all contributed to an uplift in sales as growers seek ways to help establish and then protect their

crops,” says Marcus Palmer, owner of MJP Supplies. “We’ve also bene ted from lots of repeat orders from growers who have seen the positive e ect of Algifol in previous years.”

MJP Supplies has been selling Algifol in the UK since 2007, with average sales of 2,000–3,000 litres per year.

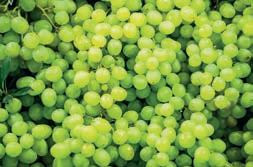

Most of Marcus’ customers apply Algifol to potatoes, sugar beet, cereals and peas, but in recent months he has received enquiries from people growing strawberries and grapes.

Field trials conducted by Neomed Pharma, the company producing Algifol, have shown the biostimulant to be equally e ective on fruit and vine crops as on arable crops.

In tests, grapes treated with Algifol showed higher total soluble solids and less acidity, with the biostimulant increasing the sugar content

and improving the overall quality of the grapes.

The trials also indicated that foliar application of Algifol positively a ected growth, quality and avour.

“Neomed Pharma’s work shows that Algifol can be e ective in the production of table grapes, as retailers can charge a premium price for sweeter and better-looking grapes,” observes Marcus.

Positive e ects of applying Algifol have also been seen on strawberries. A trial in 2019, with Algifol being applied three times – one day after transplantation, when the plants were blossoming and after the fruit set – resulted in stronger and healthier plants, no mildew on the leaves, stinger rooting and an average of 24 strawberries per plant compared to 14 on the control crop. The control crop received mineral fertiliser and three applications of leaf fertiliser.

The e ects of biostimulants, such as Algifol, have been well documented, from helping establish root structures to improving resistance to disease and extreme hot and cold weather.

It is not just Neomed Pharma’s research that has proven the bene ts of using biostimulants. A study by Colla and Rouphael in 2015 found biostimulants had a positive impact on crop growth and yield, their

nutritional quality, and abiotic and biotic stress tolerance.

Halpern et al., 2015 proved that biostimulants like Algifol enhance soil structure by simulating microbial activities and improving plant nitrogen uptake by altering plant morphological and physiological characteristics.

Made from brown algae, gathered from the ocean, dried and re ned through special processes, Algifol boasts a wealth of trace elements, vitamins, enzymes, amino acids, carbohydrates, polyuronides and growth-regulating plant hormones.

Algifol’s manufacturer – Neomed Pharma – says it is a natural nitrogen source due to the high presence of amino acids and peptides. This makes Algifol ideal for combined use with reduced amounts of N fertiliser. When used with a reduced amount of fertiliser, Algifol naturally improves the nitrogen use e ciency of the crop, producing a better crop and reducing the use of costly fertilisers.

Algifol is available in 1-litre and 10-litre cans via www.mjpsupplies. co.uk. Discounts are available for larger quantities which can be supplied to both growers and agrochemical companies for inclusion in their own fertiliser and biostimulant blends.

This year's blackcurrant season has come to an end, but the British growers' association, The Blackcurrant Foundation, reports on a challenging harvest due to record-breaking UK temperatures

The UK blackcurrant harvest started on 3rd July in Somerset, where hopes were high for favourable weather conditions for the next six weeks. However, growers were not prepared to be faced with the unexpected dry and hot conditions which were to follow. For the rst time on record and during the peak of harvest, UK temperatures exceeded 40ºC. In addition, growers harvested through the driest July since 1911, resulting in a signi cant lack of moisture in the ground.

Harriet Prosser, agronomist at Suntory Beverage and Food GB&I, said: “It has been another challenging UK blackcurrant harvest, but for very di erent reasons; last year we had frosts at owering and a very wet harvest, this year we had a good spring but an incredibly hot dry summer. We have such a small window of opportunity to pick these juicy berries, and this year our growers experienced some of the highest temperatures ever recorded in the UK right in the middle of the harvest. They have gone above and beyond toiling away, with several opting for night harvesting with lights to get the crop in quicker and make sure the blackcurrants didn't spoil in the heat.”

The impact of these extreme conditions has been felt far worse in the south-east and East Anglian regions, while for other growers across the UK, harvest has been

relatively normal. Ribena, which takes 90% of the UK blackcurrant crop, is believed to have received over 10,000 tonnes of fruit this summer.

Jo Hilditch, chair and spokesperson for the Blackcurrant Foundation, commented: “A main concern was that berries were not able to cling on to the bushes and just fell to the ground before the harvesters came through. Our harvest still requires some manual labour, despite being a largely automated process thanks to machinery, and the heat made it much more di cult for pickers who started at 4.30am some mornings. Towards the end of the season, some varieties su ered due to lack of winter chill which made for some unevenly ripened fruit in some of the later loads that went to be pressed.”

Looking forward, thanks to funding from Lucozade Ribena Suntory, the Blackcurrant Foundation’s growers have been trialling new varieties of climateresilient blackcurrants that aim to combat factors such as these prolonged dry spells, warm winters and extreme heat during summer. Nearly £11M of investment has so far aided research and development into new varieties, with some harvested this year which have been 20 years in the making. Hopefully, this will safeguard the future of the crop and help secure the livelihoods of UK blackcurrant growers.

Located in an area of outstanding natural beauty overlooking both the Orwell and Stour estuaries, Shotley Vineyard is a well-hidden treasure on the east coast of Suffolk

Charlotte Davitt-Mills and her husband Craig purchased four acres of land on the Shotley peninsula in 2017, after falling in love with the beautiful setting and views and believing it would be the perfect site to begin a glamping venture. However, this idea was temporarily put on the backburner when Charlotte realised the true potential of the 24-year-old vines on the land.

The original vines hadn’t been properly looked after for a long time, hence the couple’s initial reticence to continue the vineyard. However, after being told the vines were remarkably healthy, Charlotte begain researching viticulture to see if it was something worth pursuing. Since she was on maternity leave at the time, an initial “bit of

research” turned into many hours learning about vineyard management, and Charlotte realised how much of an opportunity it could be. In fact, she became so passionate about the vines, that she decided not to return to her previous job at the end of her maternity leave, and instead focus on the vines full-time. The couple then took on the management of other local land under vine, and Shotley Vineyard was born – covering a total of 16 acres, including the rented parcel.

The last two years have seen a harvest of around 29.5t per annum – a signi cant increase from the initial yield of 5t when Charlotte rst

took over the vines ve years ago. The second harvest yielded a little more, but as they’d had to hard-prune the vines, it limited the overall gure quite a bit. In 2020, yield was around 29t and earlier in 2022, Charlotte was hopeful that this year would see a yield of over 30t. Unfortunately, due to the record-breaking temperatures over the summer, nal yield came in at 22t – but Charlotte says while it was lower than hoped, the quality of the grapes was exceptional, and this was con rmed by the winery.

Charlotte believes the maximum tonnage the vines (as they currently are) could yield is around 35t, so all-in-all they’re doing well.

Charlotte puts this success down to the high level of care and attention given over the last ve years – particularly the fact that they use the gentle pruning method in order to look after the vines properly and prevent trunk disease.

“Last year, it took from December through to the end of February to complete the pruning. I feel you really have to get the pruning right, as it sets the tone for the rest of your season,” she explains.

“We advocate hygienic practices around the vineyard – for example, ensuring secateurs are cleaned properly, and when we rst took over the vineyard, we removed all cuttings and burned them to keep it all as clean as possible. However, now we are on top of disease through

management and a good spray programme, we have started mulching the cuttings instead to improve the soils further.”

Long term, some areas of vine are in decline slightly, and Charlotte has in her mind that she never wants to drop below a certain tonnage in order for the business to remain viable. There may be some in ll planting in the near future, likely with the same varieties, and Charlotte has been having ongoing discussions with her vineyard consultant about potentially planting up another eld as well.

She may consider replacing a little of the Rondo and a little of the Reichensteiner that are currently mixed within a eld of Bacchus with yet more Bacchus to complete the eld.

For Charlotte, Bacchus is what she considers “the gateway grape” – in that for those making their rst foray into drinking English wine, Bacchus has quite a similar pro le to Sauvignon Blanc so appeals to this audience. Shotley Vineyard produces its own Bacchus, and nds it’s one of its most popular bottles.

As well as Bacchus, Shotley Vineyard produces still red Pinot Noir, and a Charmatmethod sparkling wine which uses a blend of Chardonnay, Auxerrois, Seyval Blanc and Reichensteiner. It’s a eld blend, with all being picked on the same day, meaning there is a mix of ripe and not-so-ripe, allowing Charlotte to

Total vineyard size: 16 acres including managed land, with just over 15,000 vines.

Soil type: Clay cloam, plus a few sand pockets.

Aspect: Most is south-facing, although some is north.

Varieties: Rondo, Bacchus, Pinot Noir, Chardonnay, Auxerrois, Seyval Blanc, Ortega, and a tiny bit of Reichensteiner. The Bacchus is split across three di erent blocks, due to the ages of the vines – planting stated in the late 90s, then the last of the Chardonnay went in in 2010. The rest of the varieties are pretty much located all together.

Covering 16 acres, with a stunning view of both the Stour and Orwell estuaries the award-winning Shotley Vineyard is holding its own against the 'big boys'

retain the perfect level of acidity for the Shotley sparkling wine.

Bud burst for the Rondo this year was around mid-April, with the other varieties around a week later. Veraison was earlier than usual, at the start of August and harvest was due to be completed by mid-October.

The Rondo is harvested based on its acidity rather than sugar content as it’s picked for sparkling wine, so Charlotte watches the acids and picks slightly early compared to harvest for still wines.

Predominant disease pressure is caused by the mildews, with botrytis rearing its head as the season goes on.

This year, disease pressure across the whole country has been low; especially compared to last year, where downy mildew was widespread across the south of the country, due to the wet conditions – leading to some vineyards losing up to 90% of their crop. However, moving into Su olk and Norfolk, it was the powdery mildew that hit these more northerly growing areas hard. Fingers crossed, this year the fruit has remained pretty much disease-free, thanks to both the weather

and careful disease management.

Shotley Vineyard uses conventional farming methods to control diseases and maintain vine health, and tend to follow the Agrii spray programme as needed depending on the pressures – although they are keen to stress they try to only use what is needed for the season, rather than going full pelt. Bio-stimulants have also been used more recently to reduce the ag-chems used, as well as foliar feed.

While not a member of Sustainable WineGB yet, the vineyard is mindful of what they do, ensuring they use as little diesel as they can, extending spray windows when pressure allows and so on.

They use an Airblast sprayer, which was purchased last year, and all sta have been trained on it, allowing them to bring this in-house rather than using a contractor. The site had been fully managed at rst, but now Charlotte manages it herself with advice from a consultant as needed.

Pest-wise, wasps have been a problem in the past, especially in the drier years – so the wasp traps came out earlier this year given the hot, dry summer. Charlotte was keen to avoid the awful wasp issues of 2020, where pest damage was signi cant.

Starlings cause some problems, although a local red kite has been keeping these at bay recently. Badgers, however, appear to enjoy a grape or two in the evening, so these require some managing –particularly as they became used to having the run of the vineyard before Charlotte took it over, when they could frequently be seen shooting out from the overgrown vines in all directions.

Charlotte purchased a second-hand New Holland T40N tractor from Double Days in Lincolnshire within the last year. She is looking to build up the vineyard’s machinery collection, but comments that used vineyard machinery is like gold-dust right now, with any that comes up for sale being snapped up by European vineyards and shipped out of the country. This, Charlotte says, is one of the big issues for vineyard managers – as there’s also up to an 18-month waiting list for many new vineyard tractors, primarily as a result of steel shortages for the primary Italian manufacturers. On top of this, there’s been a global shortage of glass, as well as the wire

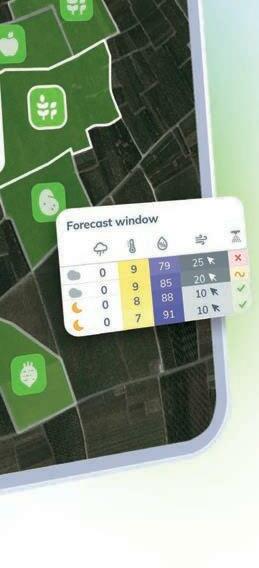

Shotley Vineyard uses a Sencrop weather station to give vital real-time weather updates, assisting them in keeping on top of issues like disease, frost and rain

Charlotte purchased a second-hand New Holland T40-N tractor from DoubleDays in Lincolnshire, which is used for various tasks around the vineyard. The availability of machinery is a particular problem for vineyards like Shotley, Charlotte says

for wine bottle cages, which is predominantly sourced from Mariupol; so long lead times mean that the focus on dry goods – which are usually not thought about until after harvest – are having to be dealt with much earlier, she commented.

As a result of the pandemic impacting on the availability of experienced pickers from Eastern Europe, who would usually work with all the local vineyards at harvest time, this will be the third year in which harvest is done using local help.

To nd pickers, Charlotte advertises on the local social media groups, and over the last couple of years she has managed to build up a reliable roster of locals who are now quite experienced in grape harvesting.

During the pandemic, training new pickers was tricky due to the need for social distancing, as well as constant sanitisation of equipment – although fortunately, this year things have gone almost back to ‘normal’.

Last year, it took from December through to the end of February to complete the pruning. I feel you really have to get the pruning right, as it sets the tone for the rest of your season.

Charlotte Davitt-Mills, Shotley Vineyard owner

According to Charlotte: “A lot has to come together in order to choose the pick day; the logistics are tricky – you need to get the ripeness and acidity levels of the grapes right, have a team ready to pick it, a lorry available to take it, and the winery having the room and the labour to take it. It’s a delicate balance and requires meticulous planning and the ability to react quickly.”

Charlotte manages both the viticulture side and the hospitality part of the business, along with the back-o ce duties. She has a full-time apprentice working with her, and also employs local lady Mary, who Charlotte describes as being “like a machine”.

Mary has lived locally since before the vineyard was rst planted, and is the longeststanding member of sta as she’d worked with the previous owners. Charlotte has found this particularly helpful, as there was no handover following the purchase of the land, so Mary is

able to provide insight into the practices that were previously carried out on the vines. She carries out various vineyard jobs, including canopy management, bud rubbing and walking the vineyard most evenings.

One area Charlotte is keen to improve is the trellising. It had been very neglected when she rst purchased the vineyard, and she has since added further top wires now that the health and vigour of the vines are improving.

Canopy management is a critical part of the vineyard’s disease management strategy. They start by tucking in, then lifting wires as needed. Following owering, they carry out leaf stripping – both to enable good air ow and also to ensure good ripening.

A front-mounted mechanical leaf stripper is used initially, then experienced labour is called in to neaten it up and take certain areas back a bit more as needed. This is particularly important near the hedge windbreaks, where leaf stripping needed to be more intensive to ensure good air ow within the vines.

Following the leaf stripping, the spraying takes place to ensure it provides the best possible coverage and avoids wastage.

Grass between the vine rows is kept under control using a trailed mower and a strimmer.

Before the vines were planted, the land had been left mostly fallow for a number of years, due to the slopes making arable planting di cult. The land was graded A/B at the time of purchase, so the soil hadn’t been hugely depleted, but Charlotte has had some soil analysis done to evaluate what micro- and macro-nutrients are lacking.

Cover crops are being used to improve the soil health as a move towards more regenerative practices, with a mix of crimson red clover, phacelia, radish, birdsfoot trefoil and two types of grass being used – the main aim being some deep rooting options for soil structure, along with nitrogen- xing species for obvious reasons.

With such early success, Charlotte and Craig have already invested heavily into the business; commissioning a purpose-built barn which acts as the hub for wine-tasting as well as providing an area to serve refreshments including co ee and cake. More recently, the duo have branched into specialist events, including foraging expeditions, supper clubs, sparkling cocktail nights, yoga in the vines, tours and tastings, and even hosting weddings.

The rst Shotley Vineyard vintage was launched in 2020, and their wine has since won awards; including a gold medal for their 2021 Bacchus and silver for their 2021 Pinot Noir at the WineGB East awards in August 2022 – the vineyard’s third year vintages. The company also o ers a second vintage English sparkling wine. The vineyard keeps around 7t for its own wines, and sells the remaining grapes to a number of other wineries across the country.

Shotley’s wine is currently produced at Bolney Wine Estate in Haywards Heath, who also purchases some of the vineyard’s grapes. This relationship carried over from the company who were managing the vineyard when Charlotte and Craig rst took it on, and Charlotte has been happy with the relationship with Bolney as well as the quality of the wine produced, so it made sense for them continue working together.

Much of Shotley’s marketing is done in-house via social media, particularly Facebook and Instagram, as well as via online wholesaler The English Vine.

Closer to home, it is stocked in the local award-winning local food hub, Su olk Food Hall, where Shotley Vineyard’s Bacchus has been the shop’s best-selling wine for the last two years’ running. In the past, Shotley Vineyard have also sold via smaller urban wineries.

Looking to the future, Charlotte is hoping to expand Shotley’s wine range and introduce a rosé (possibly a eld blend of Pinot noir and Ortega) as well as perhaps a traditional method sparkling wine.

The market for rosé is strong, with it being seen as a premium wine. Having bought some in for previous events which proved really popular, to Charlotte it makes sense to add a unique rosé to Shotley’s o ering – so watch this space.

A long-established Essex vineyard which produces high quality wines made from grapes grown on site has invested in a brand new self-propelled grape harvester.

David Williams reports

An Essex-based producer of ne quality wines has invested in a New Holland Braud 9090X grape harvester to ensure the crop can be picked in optimum condition and delivered promptly to the onsite winery

Owned by the Greenwood Partnership, New Hall Wine Estate in Purleigh in the Crouch Valley is one of England’s oldest commercial vineyards. Winemaking started there in 1969, and it remains in the same family’s ownership, managed by the third generation. There are currently 31 plantations and 50ha of land under vines, and further expansion is planned. The vineyard produces 16 varieties of grape, including Bacchus grown on some of the rst Bacchus vines established in the UK more than 40 years ago.

Until a few years ago, some fruit was sold for wine production elsewhere, but increased demand for New Hall wines and recent investment in a state-of-the-art onsite winery has led to increased production and sales. Now all the fruit is pressed, crushed, fermented and bottled at New Hall, and the range of wines includes winners of signi cant awards.

“Our primary objective is always to grow the very best fruit and harvest it in optimum condition for our winemakers to produce excellent wines,” explained vineyard manager Andy Hares. “For a single site UK wine producer our enterprise is quite large, and we don’t have the advantages of many more modern vineyards where all the vines are laid out and spaced perfectly on commercially produced trellises, and with lots of space between rows and at the ends for modern machines to turn around. Many of our vineyards were laid out when all the work was done by hand, so we continue to rely on traditional practices and manual labour.”

Employing teams of up to 40 pickers for the short harvest period meant that grapes were picked continuously, to keep the team of seasonal workers busy and ensure that all the plantations were picked in the time available. Disadvantages included an uneven supply of fruit to the winery, and that some grapes were harvested before reaching optimum condition.

“We believed that investing in a self-propelled harvester would give us extra exibility,” said Andy. “Higher work rates would allow us to ll the grape bins quickly and deliver them to the winery for processing in the shortest possible time – reducing any loss of quality through oxidation. Knowing we have the capacity to harvest them at the optimum time would also mean we could leave grapes hanging on the vines for longer while the sugars develop, and that would result in more versatile fruit and allow our winemakers to do more with them.”

Andy has managed the New Hall vineyards for seven years, and before that he worked for 10 years on vineyards in France. “Mechanical harvesters are widely used in mainland Europe, and I had seen the gains in harvested grape quality and improved working e ciency they provide. Although many of our plantations are not ideal for machine working, our more recently planted areas are suitable, and then we also have plantations which could be adapted in time.”

The New Holland Braud grape harvester was the preferred brand for its reputation in Europe, as

well as its gentle crop handling and build quality. “We already had an excellent relationship with the Ernest Doe Ulting depot team, and operate New Holland tractors,” explained Andy. “A new grape harvester represents a signi cant investment, so we had to be sure that back-up will be available if problems occur.

“We were very pleased by the reaction of the dealer as well as the team at New Holland UK, so we ordered New Holland’s 9090X agship model which arrived in early September.”

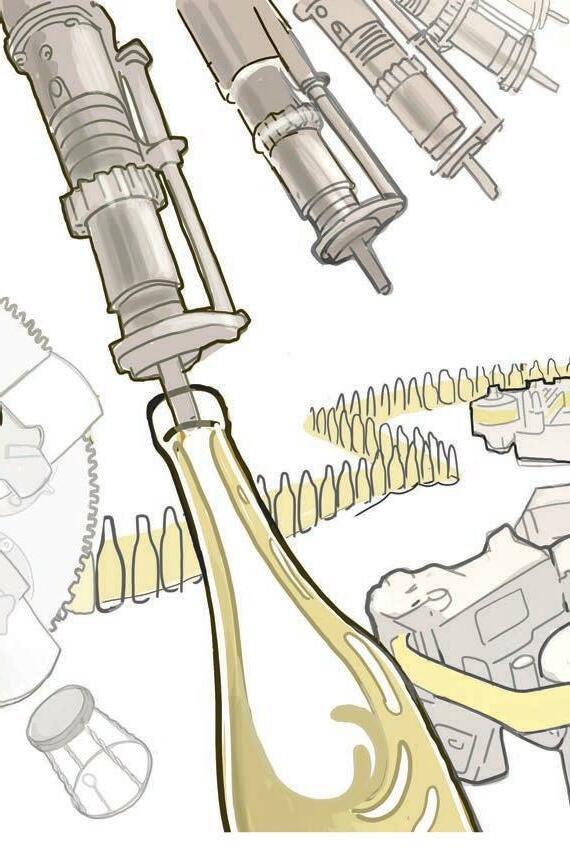

The New Holland Braud 9090X removes grapes from the vines using 24 horizontal exible bars – 12 on each side – which shake the vines vigorously at a frequency of 470–480 movements per minute, and without causing damage. New Holland’s Shaking Dynamic Control allows the operator to nely tune the shaking action to suit the crop and conditions. Falling grapes are caught by the Noria bucket system – a chain of close linked polyurethane buckets below the shaker bars on each side, which move at ground speed. The exible buckets seal around each plant stem close to ground level along the full 2.5m length of the shaker bars. They catch the grapes and juice and carry them up to the cleaning system.

The harvesting module or header containing the shaker bars and buckets moves independently of the main chassis, and automatically maintains a

The harvesting unit or header is mounted beneath the machine and moves independently of the main chassis to accurately follow the vine rows

vertical working position to follow the vine angle rather than the ground, on side-slopes up to 30%.

Grape stems are removed by a mesh conveyor and spider wheels, without damaging the grapes. The stems are discharged at the rear, then the grapes travel through air ow from four adjustable fans which gently clean the crop and remove remaining loose stems and leaves.

Clean grapes are delivered into stainless steel hoppers on each side with a combined 4,000-litre capacity, and leaves and other light materials are blown through two exhaust chutes and discharged at the rear.

The two grape hoppers are hinged at the rear, and tip for unloading. Tipping is activated from inside the cab, or from outside by a Bluetooth-linked remote control.

The main functions are controlled by an armrestmounted joystick, and the New Holland IntelliView 4 touchscreen terminal provides performance information and is used to set up and adjust the machine. Settings can be saved as pro les for di erent plantations and varieties, and conveniently selected again in future years.

The 24 horizontal bars shake the vines. New Holland’s Shaking Dynamic Control allows the intensity to be adjusted for the variety and conditions. The exclusive Noria collection system consists of a chain of polyurethane buckets which effectively clamp the vine stems and create a seal so that grapes and juice end up in the buckets rather than on the ground. The bucket movement matches the ground speed and when they reach the rear of the machine, they travel upwards carrying the crop to the destemming conveyor, cleaning system and stainless-steel hoppers

Most importantly, our winemakers are impressed by what we are delivering into the winery. Andy Hares, New Hall Wine Estate vineyard manager

A network of cameras allows the operator to monitor the crop’s progress through the machine as well as the quality of grapes in the hoppers.

The harvester is powered by an FPT engine developing 182hp, and hydrostatic transmission allows in nitely variable speed control. Drive is automatically distributed to the wheels with most traction to reduce wheel slip, and to compensate for sideslip on cross slopes. For transport only, the front wheels drive and maximum speed is 30kph.

Andy quickly got used to the machine. “The rst opportunity I had to try it was when the grapes were ready for harvesting and, although I knew the basics, I struggled to achieve good results.

New Holland’s grape harvester specialist, Philippe Boisseau, travelled to England and helped me set up the machine. There is a lot of technique involved, and as soon as he demonstrated the correct procedure for setting up the machine, operating it became much easier. Very small changes to the settings make a big di erence.”

There is a very good view from the cab during harvesting and on the road

Powerful fans create air ow to remove lighter materials such as leaves and loose stems which are then discharged through a pair of outlets at the rear

“We were all amazed by the quality of the harvested fruit, and particularly the clean sample and lack of damage. Experienced pickers each achieve 400–450kg per day, but the New Holland picks more than 7,000kg in 3.5 hours, and achieves this operating at a modest 2.0–2.5kph although the recommended speed is 3.0–4.5kph, and it will work at 7.0kph when conditions are ideal.

In theory, it could complete our whole harvest in only 70 working hours, and knowing we had that sort of capacity available contributed to a more relaxing harvest. We were able to deliver just as much fruit as was required by the winery team, then wash the machine down and do something

else until more grapes were needed. In hot weather we harvested early in the mornings and in the late afternoons – avoiding the mid-day period when temperatures were higher and the quality of harvested fruit declines most quickly.”

Wastage has also been reduced, continued Andy. “Varieties such as Bacchus are di cult to pick by hand as the bunches are well hidden by leaves, so we usually nd a lot left on the vines which were missed during manual harvesting. The New Holland gets almost all of them, and there are very few lost through the cleaning system either. It’s very e cient.”

Asked whether the older plantations have caused problems for the machine, Andy said there have been fewer than expected. “Where we have sleepers or concrete posts which are wider than the gap between the shaker arms and the two rows of buckets there was no point trying as the machine would have been damaged, but even where the narrow concrete end posts were at an angle, the machine coped well. We have been able to use it in some areas where we thought we would have to pick by hand, and the experience gained this season means we know what additional pruning and trellis modi cations are needed for next year.

“The vines themselves have su ered very little damage during harvesting. Obviously, they were planted and pruned with manual picking in mind in the past, but the exible shaker rods followed the rows well. The New Holland Braud design is very e ective.”

Andy said that although some members of the vineyard team were concerned when mechanical harvesting was rst suggested, it didn’t take long for everyone to become convinced of the bene ts once the machine started work.

“Most importantly, our winemakers are very impressed by the sample we are delivering into the winery,” he stressed. “The harvester simply improves the quality of what we already have here, and it allows us to pick at the point which is best for the fruit – not just when we have labour available. We made the investment to maximise our grape and wine quality, but an additional bene t is that we can operate with a smaller team of just 10–12 manual pickers, so management has been easier, too.”

“Demand for small tractors and specialised machines for vineyard use has increased considerably in recent years,” explained Ernest Doe area sales manager, Derek Peck. “We are very pleased to have supplied New Hall Wine Estate with the rst New Holland Braud grape harvester sold new in the UK and believe it will provide major bene ts for this long-established business.

“We are working closely with New Holland to ensure that we can provide back-up for the grape harvester whenever it is needed and have already invested in product training for several of our engineers so that they understand its design and operation.”

The New Hall grape harvester is the rst New Holland Braud 9090X sold new in the UK. The Ernest Doe and New Holland UK teams received training at the dealer’s Ulting headquarters before the machine was delivered to the customer. Pictured (l-r) are Arron Heaps, David Smith, Steve Cronin, Nathan Keeble, Dieter Goderis, Ian Roberts, Jo Matthews, Derek Peck and Harry Underwood

The New Holland Braud header width is adjustable, and the machine copes well with mis-shaped and angled posts

A pair of stainless-steel hoppers hold up to 4,000 litres of grapes, but the machine’s high work rate meant there was little time pressure, and the hoppers were emptied frequently to reduce damage and minimise the time between picking and delivery to the winery

Pictured (l-r) Ernest Doe area sales representative, Derek Peck; New Hall Wine Estate vineyard manager Andy Hares; and New Hall Wine Estate general manager, Becki Trembath

A Kent-based contractor who specialises in vineyard establishment and maintenance has invested in one of the rst new Weaving Vineyard drills to establish cover crops and herbal mixes for his customers this year.

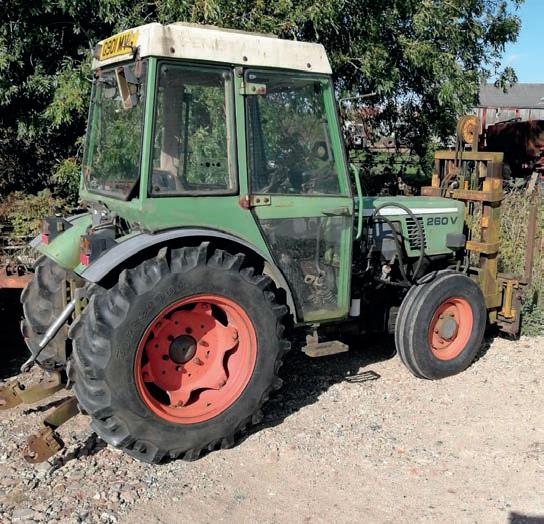

Sam Barnes grew up on his family’s vineyard, which was planted in 1969, and continues to assist with the management, working with his brother and parents. He started his own business in 2017, trading as SJ Barnes Ltd, and operates from a base at Biddenden providing a specialist contracting service for vineyards throughout the UK. Vines are imported from France and Germany, and his fourman team has planted more than half a million vines for grape producers in 15 counties this year.

As well as supplying the vines, Sam helps plan and layout the vineyards, and supplies and erects fencing, as well as post and wire trellises. His eet of specialist machinery includes two

trailed grape harvesters – the rst bought in 2019, and the second one last year because of rapidly increasing demand. Four Fendt narrow vineyard tractors are operated, as well as a John Deere used for spreading compost in vineyards and orchards, and a JCB Fastrac does the vine planting.

“We operate specialist machinery that most vineyards couldn’t justify owning, so it makes sense to use our services and have access to the best equipment available,” explained Sam.

“Much of our maintenance work is establishing, maintaining and repairing grass and cover crop strips between the vine rows, and we built our

own combination power harrow drill with a mounted air seeder several years ago especially for the task,” explained Sam. “It works well, but in recent years increased use of complex seed mixes highlighted limitations of its air seed delivery system, as seeds of different sizes and densities became separated in the air flow, and very light seeds just bobbled around.”

To improve compatibility with a wider range of seed mixtures, Sam purchased a Weaving Magnum last autumn to replace his current seeding unit. However, he quickly realised that a better solution would be to invest in a complete drill which was purpose designed for the job.

“Fitting the Weaving seeder to our existing power harrow drill base would have worked, but I discussed with Weaving Machinery sales director Simon Weaving whether there was anything more suitable that he could offer. He was keen to help, and the solution he proposed was a bespoke narrow version of the Weaving Mounted GD Drill – which was basically the standard drill cut in half with nine coulters and a 1.5m seeding width.”

Sam’s Weaving drill proved successful and, in response to growing demand for specialist vineyard machinery, Weaving has put the drill into production, and it is now available to order.

The new Weaving Vineyard Mini GD Drill is described by the manufacturer as the ‘little brother to the Mounted GD Drill’, and the seeding coulter design is identical. There are two versions – in 1.5m and 2.0m working widths, both with 166mm row spacing and adjustable coulter pressure up to 200kg to ensure e ective penetration even into dry, hard ground.

ap is released onto the seed, and a following press wheel closes the ap and seals the slot – retaining moisture and ensuring e ective seed to soil contact. The versatile design allows direct drilling into existing grass and cover crops, or it will perform just as well establishing crops into pre-cultivated ground. Each pair of discs is mounted around a central pivot pin, allowing the coulters to pivot to avoid obstructions and to follow the direction of travel.

Sam’s drill has been used for seeding in a wide range of situations, including short grass where the lack of surface movement and e ective press wheel action means it is di cult to see where it has been.

Sam has been using his Weaving drill for almost a year, and its exible design which allows drilling direct into existing vegetation or into pre-cultivated ground has proved a big advantage. “Since investing in the new drill, there have been many situations where we have been able to drill straight into the existing vegetation, avoiding the need for pre-cultivation.

Weaving’s new Vineyard Mini GD Drill is available in 1.5 and 2.0m working widths and is capable of direct, low-disturbance-drilling into existing cover crops or grass, or planting into pre-cultivated soils

The proven GD double-disc coulters achieve minimum surface disturbance. A large diameter angled outer leading disc cuts an opening, and a slightly smaller inner disc lifts a flap of soil and holds it while the seeds are dropped below. As the machine moves forward, the

“We have kept the power harrow drill as there are situations where that gives us an advantage. Vineyards are naturally a controlled tra c environment in which the wheelings remain in the same place year after year,” he said. “In time ruts develop, and we use the power harrow to redistribute soil and create a level surface, then we plant the grass or cover crops into the loose soil using the new Weaving drill.”

Will Barnes (left) is the drill’s main operator, and he is pictured with Sam Barnes

On the day Fruit & Vine visited the drill, it was establishing a complex mix of 27 varieties of seed between the vine rows at a mid-Kent plantation

Since investing in the new drill, there have been many situations where we have been able to drill straight into the existing vegetation.

Sam Barnes, SJ Barnes Ltd

On the day of Fruit & Vine magazine’s visit, the drill was establishing a wild ower and herbage seed mix containing 27 varieties of seed between the vine rows of a large plantation in mid-Kent which had been planted by Sam’s team earlier this year. The vines were planted 1.0m apart, in rows spaced at 2.2m and up to 280m long. Accurate RTK guidance had been used during planting to ensure rows were perfectly straight – creating ideal conditions for the Weaving drill to achieve high work rates.

“In this sort of environment we can easily drill 8–10ha per day,” continued Sam. “Work rates are considerably higher than we could have achieved using the power harrow drill, and our fuel consumption is lower too. The Weaving drill is well made and heavy which helps ensure e ective penetration, but it’s very easy to pull.”

Other advantages of the Weaving drill over the power harrow-based seeder include lower wear rates when operating in stony ground. “Many of the vineyards we look after are on inty soils and the Weaving drill’s disc coulters su er less wear and pivot to work around obstructions which reduces the risk of breakages,” added Sam.

The new drill has worked with a wide range of seed mixes during its rst year’s use. Each mix requires a new calibration but the main user, Will Barnes, said the process is quick and easy. The speed of the hydraulic-driven fan has a wide range of adjustment to suit seeds of all sizes and densities, and a rubber exhaust boot at the top of each coulter allows excess air ow to be discharged while the seed free falls directly into the slot created by the discs.

The 300-litre hopper holds enough grass seed to plant 3–4ha, and an Artemis Lite metering system with RDS control and automatic rate management by GPS speed monitoring, ensure the correct rate is used. Extra high seed rates are available by altering the gearing, but the standard setting has been suitable for every situation so far.

Will Barnes is the drill’s main operator, and he commented that he likes the simple, reliable design and excellent build quality. “If anything, it is over made, and we like that as it means it will last well and put up with intensive use. It’s easy to set up and look after, and the folding rear steps provide safe access to the hopper for checking and lling.

“We’ve used it in a variety of conditions including hard and soft soils, and we have never had a coulter blockage. The coulters themselves are no trouble – they pivot around obstructions, and because they move independently their contour following capability and depth control is superb. Additional weights can be added, but we haven’t needed them so far.”

“To give crops the best start and achieve optimal establishment, seeds must be placed at the ideal depth, and they need e ective seed-to-soil contact. The new Weaving drill achieves this in a wide variety of working

conditions,” concluded Sam. “We are achieving significant time and cost savings, but these aren’t only due to the higher working speed. Previously relying on the power harrow drill –we usually had to carry out additional operations including spraying o the existing vegetation, then cultivating, drilling and rolling, whereas the Weaving drill requires only a single pass in most situations to achieve successful plant establishment.

“One of the most impressive features of the Weaving drill is its ability to improve grass areas. Where vineyards have been maintained in good condition, we have been able to retain the existing surface structure and just stitch the grass in. The technique works well and the results are impressive.”

Sam said that he is very pleased with his choice of drill. “The Weaving Vineyard Mini GD Drill works well and achieves excellent results in a wide variety of conditions. Reduced soil disturbance helps reduce moisture loss, and seeds are placed into an ideal environment to establish successfully.

“For most situations the Weaving is the best option, but retaining our existing power harrow drill gives us added exibility and means we can o er whichever solution is best for our customers.”

The double-disc coulters are the same as used on the full-size GD Drill. The discs have a slight stagger, and the leading disc cuts an opening, and the second disc lifts a ap of soil and holds it while the seed is placed beneath. A press wheel at the rear controls the seeding depth and closes the ap while ensuring effective seed to soil contact

The 300-litre hopper is easily accessed for lling

Pictured (l-r) are tractor sales manager, Steven Haynes; Fruit &Vine sales executive, William Taylor; marketing and communications manager, Gillian Haverson; workshop technician/assembly So a Grimes; and assembly trainee, Brandon Moore

One top tip of the vineyard trade is simple – use the right equipment. One reason commercial vineyards tend to get a better crop load of clean fruit at harvest is because they use commercial grade equipment with very speci c productivity characteristics. Steven Haynes from Farmtrac distributor Reesink Agriculture explains more

Commercial equipment makes the world of di erence for customers with a vineyard larger than an acre, and top of the wish list for most is undoubtedly a tractor. So, what makes a good purchase in this category?

First up is a low-pro le design and narrow width. The next, features and bene ts at an attractive price point. An example of a tractor which meets these requirements is Farmtrac’s FT6075EN.

Farmtrac is a relative newcomer to the tractor arena in the UK, but not to the global tractor market – the brand actually comes from one of the world’s top tractor manufacturers, which means customers can be guaranteed of a cuttingedge, cost-e ective and innovative machine.

The tractors incorporate world class components including transmissions designed and produced by Carraro and hydraulic systems from MITA, to deliver a superior performance whether working the land, towing trailers or hauling equipment.

From the range, the FT6075EN is a very attractive proposition for vineyard owners. Starting at

under £35K, it delivers a powerful combination of technology and fuel economy, while also being narrow enough to work between the vines.

The engine is designed to meet the relevant emission standards with an eco-friendly, Stage 5 engine which still brings the same amount of power from the 3,680cc CRDI diesel engine but with far fewer emissions. It not only o ers bestin-class torque to carry out heavy operations but also delivers 75hp at 2,000rpm.

It meets global agricultural and commercial needs with its 12x12 speed transmission or optional 24x24 creeper transmission options and heavy-duty lifting capacity of up to 2,500kg, in a slimline and nifty package. Plus, the Smart Life feature means quick lifting and lowering of implements during headland turns.

It brings the latest technology for quieter operation and faster movement in both forward and reverse from its synchromesh gear box technology. Rear axles with epicyclic reduction means less wear and tear and longer life for the components and less maintenance. A durable and heavy-duty mechanical front wheel drive axle

gives more traction in tough conditions.

It has multiple speed availability for di erent applications as per di erent soil conditions, selectable 4wd, independent dual-speed rear PTO, position and draft control, rear hydraulic spool valves and trailer brakes and a heavy-duty three-point linkage system.

A at and integrated platform gives more leg space for the operator and ergonomic features o ered such as side-shift gear levers and deluxe seat make for improved productivity.

The narrow series tractors are perfectly suited to work in both the vineyard and soft fruit applications and that’s due to its compact dimensions. Customers can look to have the tractor with a neat folding mid ROPS version or a low-pro le air-conditioned cabin. Whatever option you choose the FT6075EN is sure to deliver on performance in the eld.

All-in-all and taking into account the warranty of up to three years, supported by Reesink Agriculture as the UK distributor, this tractor is a good value, good choice option for the price point.

Power: 75hp

Lift capacity: 2,500kg

Transmission: 12x12 manual

Rear linkage: Cat 2 PTO: 540 and 540E

Spool valves: 2 DA

With labour shortages being a constant battle with UK growers, Kirkland UK says it has researched and sourced the ideal machinery solutions for this seemingly perpetual problem

Tecnofruit harvesters are the ideal machine for commercial orchard use, supplier Kirkland UK says. Available in two models, with various options including self-levelling and a semi-automatic bin trailer, the two Tecnofruit machines come with the following bene ts:

• No binning out – Load and unload your harvester from the rear using either a rough terrain forklift or the unique Z4 bin carrier. This means the harvester is the rst machine to pass down the row, therefore not driving in ruts – especially in a wet season.

• 24/7 after-sales support – Harvest is a hectic time for every grower, so Kirkland says it is proud to support UK fruit growers with its 24/7 aftersales support during harvest, alongside a huge supply of parts available for any breakdown.

• Cost-e ective – The harvesting labour cost can be reduced by up to a half, with estimated savings of about €15,000 for 10ha (data recorded in CCA) thanks to a smaller number of operators with a higher yield per person compared to traditional harvesting systems and waste reduction.

• Future-proof – Tecnofruit manufacturer

Darwin Harvest Group and Tevel Aerobotics Technologies have joined forces to create the world’s rst fully automated harvester. Providing real time information on quantity,

quality, size, weight, and colour of the fruit picked, it is also available as a 'bolt-on' solution meaning you can upgrade your current Tecnofruit fruit-picking harvesting system.

Hadlow College is one of Kirkland’s customers, and the college’s STEM lead, engagement and nance, Zoe Smith, says it is excited to be part of the future of harvesting. “Hadlow College is delighted to be working with Kirkland UK on our new orchard and vineyard project. We chose the Tecnofruit harvester as it perfectly matches our needs, and allows our students to be hands-on with some of the latest automation available to the industry.

“It was available in di erent sizes, which meant we could pick the one suitable for us, and will also have a camera system retro tted later this year. This camera system will allow us to scan all the picked fruit, and our sta and students will then link these data with information gathered throughout the growing season from environmental sensors and drone footage, giving us a complete picture of fruit production.

“We’re excited to be part of the future of fruit growing. Kirkland have been very supportive, explaining and demonstrating all the options available and helping us to select the most appropriate equipment. We’re delighted to have such partners in the industry.”

Prime Produce is another of Kirkland’s impressed customers. “Prime Produce already operates 12 Tecnofruit machines across two farms,” says the company’s head of farming operations, John Clark. “The machines help us work faster, smarter and in a less expensive way than a traditional hand picking, laying out bin system.

“No laying out of bins in the orchard is required; all bins arrive on one trailer to the eld and leave on the same trailer having been lled and back to the farm, with the trailer on a constant loop picking up and delivering bins.

“This means the bin team have shorter days, and each picker is pulled along to the speed of the machine, meaning no one person can slack without being noticed within the team.

Teamwork is built just by using the machines – one team leader per machine helps keep the machine working at maximum e ciency throughout the 8–9 hours of the shift.

“This all leads to less overtime due to the better use of all the pickers’ time, all pickers working at the same speed and generally improved team e ciency.

“Quality control is essential in this business, and with one QC working across six machines, being able to see the picking, apples travelling to the bin, bin lling and being able to look over the bins as they drop o the back of the machines is a real positive. As the QC is moving between machines, they are able to assess what fruit is left on the trees plus any fruit that is on the oor.

“Being able to have all 12 machines working at full capacity, and having the option to use the machines for two eight-hour shifts per day without having to pay overtime if we need to bring harvest end date forward is a massive plus for our business.”

“Gala is a good option for us because it is the most popular UK apple; plus, because it is frosttolerant, it all but guarantees you a crop.”

Founded by their grandfather just after the war in in 1921, who started by growing 16ha (40 acres) of fruit, the family business soon expanded to 101ha (250 acres). The farm was subsequently inherited by David and William’s mother and aunt, who eventually split it and sold most of it o ; leaving 16ha, which their mother continued to farm. The brothers, who took over in 1998, have succeeded in rebuilding it back up to 90ha in this time.

Just over 70ha is dedicated to apple trees, and well-known apple varieties Gala and Braeburn are their mainstays. Yields are upwards of 50t/ha for established Gala, and average 70–80t/ha for Braeburn.

They also grow 3.2ha Cameo, and 6.5ha of new trademarked variety Magic Star.

David comments: “This new variety is becoming popular, because not only does it taste good but it also stores very well – it can be stored

for more than 12 months, opening the possibility of year-round supply.”

The average age of the apple trees is between 9–10 years, with none older than 17 years, and his strategy is to plant an average of 3ha/year with new trees. Most orchards are now on the post and wire system – 3.5m alleyways, 1m apart within the rows, and 3m high.

“Between 60–70% of the apples we grow are Gala, which are grown as clones. The newer clones with desirable traits such as better skin colour, early ripening or apples which are simply easier have become available,” he explains, noting that older clones can have stripy green variations in colour. “Once we nd a particular clone has been outclassed, we change it.”

Some of the Gala clones are Gala One, Royal

However, it has a tendency to overset, so needs thinning by hand to achieve the right size pro le for the market – which is 55–80mm.

“The most useful size is 62–68mm, so we aim to get as many as possible to that size range,” David shares.

This is because apples are paid for by the kilo with a linked expectation of count, but there is a minimum number of apples per pack, he explains.

“If you put eight larger apples in a pack, you are giving away kilos.”

Braeburn are more sensitive to frost, more variable in yield, and hence may become more overset every other year. “Anything that grows over 80mm is left in the eld, as it is has no economic market,” he notes.

In total, between 10% and 15% of the crop can be left in the eld, which hits pro tability.

The primary focus is on good quality top-fruit farming for Kent-based brothers and apple, pear and cherry growers David and William Riccini, of W&D RicciniDavid Riccini has recently begun experimenting with planting wild meadow mix as a cover crop in every fourth alleyway in newly planted orchards instead of plain grass. The aim is to encourage pollinators, improve soil health and suppress problem weeds

On the topic of weed control, David comments: “There are ongoing discussions about best practice, but we recently made the decision to continue to apply a herbicide in a strip under the trees because the soil is not cultivated there, and cultivation is known to release carbon dioxide.

“Firstly, we don’t want trees competing for water and nutrients, but also if you leave weeds such as cleavers and thistles, they can grow quite tall, and go through the branches. Then there is a risk that they may scratch and dis gure the fruit.”

Asparagus, as a weed, is common in the area and David has found it to be insensitive to the normal range of herbicides, so he has to resort to having it dug out.

Being based in a drier corner of the country means

that scab (Venturia inaequalis) incidence is slightly less prevalent as in other areas of the country.

The fungus survives the winter on fallen leaves and unripe fruits, forming ascospores. When the temperature warms up, these ascospores mature and are subsequently released when they become wet. The pathogen then spreads by airborne spores.

Once infected, plants produce cork as a defence against further growth of the fungus.

“Some of the new varieties are more scab resistant, but wet springs can still play havoc with the blossom, leaves, petioles and the developing fruit,” he says.

Discussing post-harvesting, David reveals that they do not have any grading or storage facilities

on the farm.

“This would need a great deal of capital to set up e ciently, so we prefer to use professionals who are specialist in this area and possess the sophisticated equipment to realise the necessary economies of scale.

“We aim to concentrate on growing the best crop possible, to invest in orchards and the associated equipment, and not being distracted by extra administration tasks and onerous volumes of paperwork that the running of a pack house involves,” he emphasises.

Once harvested, the apples and pears are sent to AC Goatham & Son, where they are stored, graded and packed before being supplied to Sainsbury’s. The cherries go to AR Neaves for packing, marketing through Berry Gardens, and then are subsequently sold in Marks & Spencer,

“One of the problems with cherries is the poor net return farmers receive when they are sold in packs of 200g,” laments David.

The packaging process costs the farmer around £2.25/kg, he says, adding that there is also an environmental footprint of putting them in a plastic punnet which is heat sealed in with polythene.

“While we understand the supermarket is probably trying to keep the pack below a certain price to achieve a price point of acceptability, it really does not work for the growers.”

The minimum size in the US is equivalent to 454g, and this, he points out, is a much more e cient and sustainable size.