“Graham Johnston’s father helped during the early stages of building this special Mini but, alas, did not live to see the car completed — hence its special registration plate, TO DAD”

Graham has always been something of a Mini lover, his first example being a white and black British-built Cooper that he owned for a few years until he was 21. Driven as an everyday car, the Mini was used by Graham to travel from his parent’s house in Howick to his place of work, at that time NZ Steel in Waiuku, a 100-kilometre round trip. As well, the Mini was pressed into service for skiing trips to Mt Ruapehu, and once to Mt Hutt.

With that first Cooper sold, Graham wouldn’t return to Mini motoring until he was 27 — now residing in Wellington, he acquired an orange and black car.

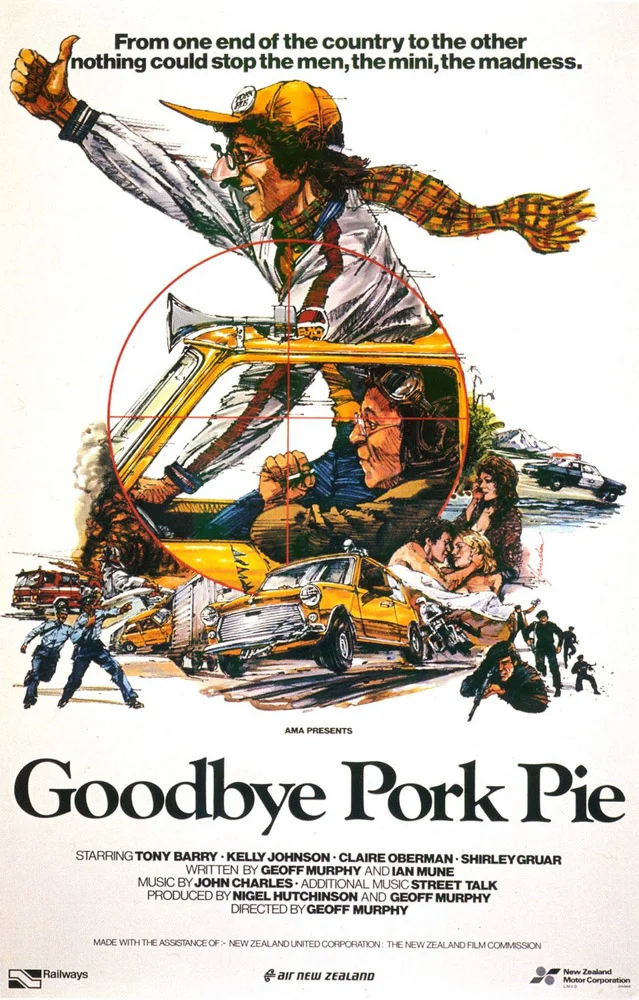

This one was a bit special, in that it had been worked on by Peter Zivkovic. If that name seems familiar, just ask any Mini enthusiast — they’ll all know Peter as the man who did most of the stunt driving for that iconic Kiwi road movie, Goodbye Pork Pie.

At the time, this Australian-assembled Leyland Mini was running a 1310cc motor, and sucked petrol from its twin fuel tanks through a Weber downdraught carburettor. After purchasing the car, Graham returned it to Zivkovic’s Johnsonville workshop for further alterations — including the addition of racing seats and a fibreglass bonnet and boot lid. Additionally, the downdraught Weber was swapped for a 40 DCOE carburettor, while later-model disc brakes were fitted up front.

Long-term project

Graham left New Zealand in 1995, heading towards Liverpool in the UK to fulfil an IT contract. While he was away, his Mini found a new home at his parents’ place in Eastbourne, Wellington. However, Graham had definitely not forgotten his car, and a list of go-faster bits, provided by Peter Zivkovic, accompanied him to the hometown of The Beatles. There was nothing too extreme on the list — a sportier camshaft, four-speed SCCR gear-set and larger valves, plus a few more items. As Graham slowly ticked off the parts on his list, he shipped them back to New Zealand.

Graham’s plans to return to Wellington and personally supervise the installation of all these performance parts at Zivkovic’s workshop soon fell apart, and in the end he remained in Liverpool for the next three years.

In the meantime, he commissioned Zivkovic to start work on the Mini, who commenced transforming it in late 1996. At this time Graham’s father became the go-between, effectively acting as project manager, as he regularly visited Wellington airport to pick up the parcels of parts sent by Graham from the UK, and then delivered them to Zivkovic’s workshop. As well, he kept Graham in touch with progress on the Mini — and the bills that needed to be paid.

Unfortunately, Graham’s father passed away while he was living and working in Liverpool, and he never got to see the end result of his involvement with the Mini. Graham returned to New Zealand, where he continued to work on the project.

Targa interlude

While work continued on Graham’s Mini, in 2000 he took on a short-term contract based in Christchurch and, whilst in the Garden City, he spotted a Cooper S at an auto-electrical workshop. A deal was done, and Graham purchased the Mini and drove it back to Wellington after he’d completed his contract.

His initial plan was to freshen up the Cooper’s motor and gearbox and use the car as an everyday runner — evidently Graham was suffering from Mini withdrawal pangs, as his other Mini remained off the road as its transformation continued. Then he cottoned on to the Targa Tour, and quickly decided that it would be a lot of fun, so he entered the 2002 event. Peter and Graham dropped a fresh 1420cc engine into the Mini — this motor running a Longman GT-6 head, twin 1¾ SU carburettors and a rally-spec camshaft.

The mildly modified Mini went well on the five-day tour, the only problem being a gear-linkage roll pin that decided to break just as the Mini prepared to complete a few laps of the Taupo race track. The car was towed to the first garage the team spotted in Taupo and, in another of those typical Targa moments, it actually had a stock of the correct roll pins so the Mini was very quickly fixed and back on the road.

Graham hung on to his Targa Mini until 2008 when he sold it to a friend, replacing it with a S4 Lotus Seven — one of the locally produced examples manufactured by Steel Brothers in Christchurch. Graham’s friend, now living in Brisbane, still owns that Mini, and is currently in the process of returning it to original specifications.

In the name of the father

Although work had commenced on Graham’s Mini in 1997, it wasn’t finished until 2002. Since then, the Mini has only completed around 2000 kilometres, and is now based in Auckland following Graham’s relocation from Wellington. He attended a few car shows over the summer months, but he’s still tweaking his Mini, and future plans include adding some more carbon-fibre parts, courtesy of Carbon Weezel in the UK, and returning the car to Peter Zivkovic (now based in Tauranga) for the installation of a fuel-injection set-up.

Of course, Graham also added that personalized plate – TO DAD – in recognition of the part his father played in the overall project.

The Mini’s modifications

- Body: Fully stripped and dipped, professionally repaired and rust proofed, front and rear de-seam, custom fuel filler recessed into bodywork, alloy Aero-style fuel cap, Euro Group 5 arches, rear seat removed. Subframes, pedals and steering-column cover powder-coated blue. Carbon-fibre bonnet (further modified to fit air filter), boot, bumpers, headlamp rims, rear number-plate light assembly and side mirrors, full factory tinted glass, clear front and rear indicators, halogen headlights, MkIII S grille.

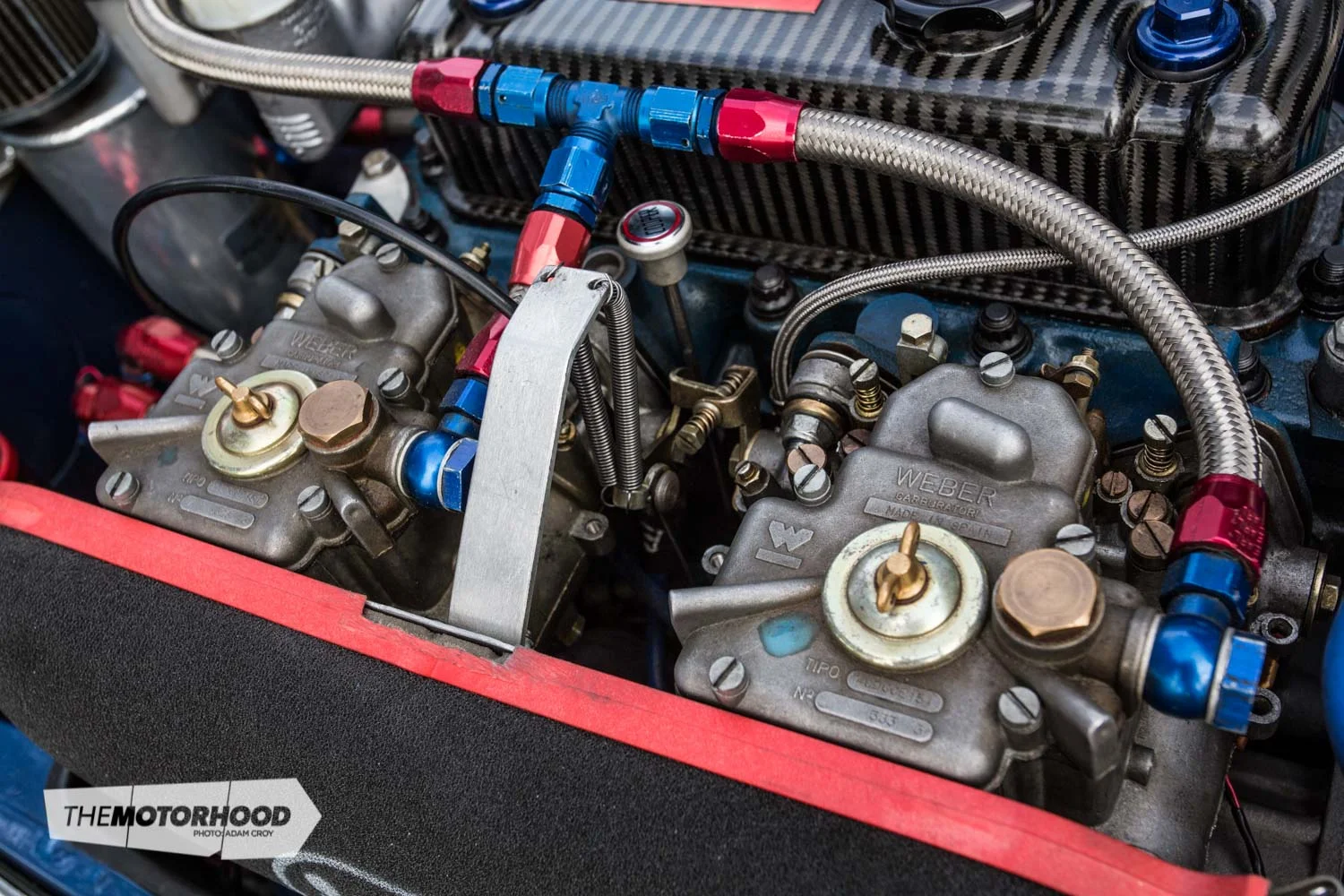

- Engine and Gearbox: 1330cc, Omega +60 thou pistons, S rods (lightened, balanced and stress relieved), S crank, custom 290 cam, stage IV AKM seven-port head, twin Weber 40 DCOE carbs, ITG air filter, Slark Racing straight-cut cam timing gears, YellaTerra full 1.5:1 roller rockers, ARP bolts throughout, Ultra-lite steel flywheel and back plate, custom alloy radiator with silicone hoses, electric fan, custom-alloy catch can with breather, KAD engine steady, Playmini carbon-fibre rocker cover, MSD ignition, oil cooler, fuel cell, Facet red-top fuel pump, carbon-fibre battery cover, Maniflow stainless large-bore LCB and stainless single-box exhaust, braided hoses with Earls fittings throughout, JKD five-speed SCCR gearbox with SC drops, central oil pickup, JKD anti-torque-steer kit, KAD quick shift, four-pin diff, heavy-duty clutch

- Wheels and brakes: KAD alloy four-pot front, slotted rotors, KAD mini-fins rear, KAD alloy rear arms, KAD alloy handbrake quadrants, braided brake hoses, KAD pedal box, three-piece 10x6.5-inch Spectrum alloy wheels, Dunlop Formula R tyres

- Suspension: Spax adjustable dampers plus Hi-Lo front and rear, fully adjustable tie-rods and forged one-piece bottom arms, KAD rear anti-roll bar

- Interior: Custom carbon-fibre dashboard, Curley Motorsport carbon-fibre door, 3/4 and parcel shelf panels. Stack electronic dash, full John Cooper Garages signature alloy interior, Motolita John Cooper signature steering wheel, Racetech seats and clubman harnesses, push-button start, battery cut-off switch, adjustable brake bias, fire extinguisher, roll bar, custom Autostyle mats, Newton Commercial headlining, custom carpets

Car built by Peter Zivkovic Race Car Preparations Limited, Wellington.

Buy a copy of the magazine this article first appeared in below: