Forklift history -from 1900 to 2019(I, II)

The history of the forklift truck is divided into seven parts, here are the first two parts.

1. The birth of a miracle, 100 years ago, the forklift story began

The establishment of a forklift truck is one of the important events in the twentieth century, which has a great influence on the development of the world industry and economy. In turn, the economic downturn and boom have had a significant impact on the development and production of new forklift products, as well as demand. At the beginning of the last century, the establishment of a mushrooming number of companies stimulated the development of new methods of work and the transportation of products and materials. Since the first large production association emerged in the United States, the founders of the forklift industry have been Americans. Companies such as Clark, Towmotor, Hyster, Baker, and Yale are now driving the ground transportation market.

- 20th century: Technological Revolution

In 1903, Henry Ford founded an automobile manufacturing company and introduced the Model T. Ford was not the first Volkswagen carmaker (launched two years ago by Oldsmobile), but the Ford brand became the biggest. Over the past 25 years, Ford has sold more than 15 million cars, and nearly every American family owns a car in the 1930s. That same year, when Ford got into the car business, the LAHITTE brothers, along with Wilbur and Orville, built a flying "heavier-than-air device". They managed to keep their Zhang Aloft for 12 seconds and flew a distance of 37 meters, which marked the birth of aviation. In the early 20th century, after 1840 was invented by George Stevenson, the steam locomotive covered the United States. The small residential area through which the smoky train passed was transformed into a large industrial area.

Technological innovation will not only affect freight transport equipment. Hand Carts and mobile platform loaders have been used since the late 19th century. At the beginning of the 20th century, machines with mechanical controls appeared. In the first World War, because of a severe shortage of labor, trolleys with Electric Motors and traction batteries were widely used. The platform was not immediately transferred to the electric traction system, which not only can transport goods but also can carry out lifting operations. Only at the end of the first World War did the designers of mechanical equipment see the advantages of stacking over simply moving goods horizontally, which increased the productivity of warehouse operations, since then, it has created a "high lift" platform truck.

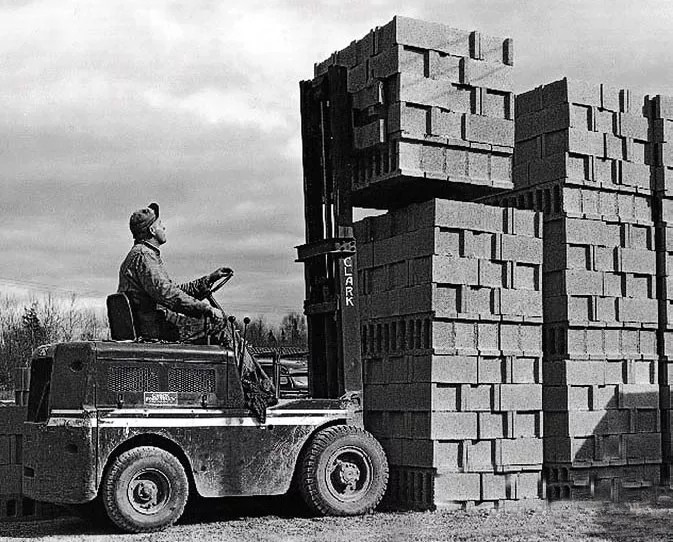

1928, Clark, three-wheel platform loader

1921, One of the first Clark platform tractors

CLARK: The birth of the world's first forklift

You may have been arguing for a long time about who made the first loader. In the 1920s, UK based Ransoms & Rapier made a product similar to an electric forklift. In 1922, Miag developed the world's first "lift-up" forklift, which was sold five years later as the predecessor of the German forklift. But it is safe to say that Cluck was a pioneer in the production of forklifts. The real breakthrough came when a group of workers founded the American company Clark Equipment Co. The foundry of the United States. In 1916-1917, machines used to transport sand and raw materials became the pioneers of industrial forklifts.

In those years, there was still no engineering solution to enable diesel forklifts to use the differential (a system for distributing torque between wheels). Eventually, the previous product had a gasoline engine and three wheels. Due to the defects of the steering system, the turntable is very narrow, and the forklift itself is not very convenient or safe. To turn left, the operator turns the steering wheel to the right, to the right to the left. Forklift truck didn't have a brake on, and it was the easiest way to stop herself from hitting the first obstacle. Despite these shortcomings, the forklift did well. Visitors to the factory soon realized the potential value of the product and began ordering forklifts for their company. It should be noted that platform trolleys were most common in the years before the first World War. That changed with the arrival of the officers, who saw the electric tricycle as an ideal means of transporting explosives. At that time, electric vehicles were used in the United States army warehouses. Usually, the warehouse is located at the bottom of the bunker, the bottom of the bunker is a long road. It is totally unacceptable that batteries often fail in the middle of a drive and dangerous goods remain in the open air. Clark's technicians solved the problem by adding a forklift truck with an internal combustion engine. At the same time, they saw the use of electric tricycles to transport explosives, is a rather ideal tool.

On the eve of the war, Eugene Cluck got a priority order from the army to build a tricycle forklift. His company assigned it a separate production line and built a factory. In 1921, two to five-ton trucks were developed. It was the first fork-lift truck with a gasoline engine and a lifting mechanism built by Clark and operated by a standing driver. The forklift truck was equipped with tires made of durable rubber and, for the first time in nearly two years, added a gantry that allowed it to stack goods at a given height.

The Duat forklift from Clark's 1926 Promo

1927 Clark three-wheeled Tractor that provides tight protection for the driver's workplace

Clark's Duat, which is essentially a trike powered by a gasoline engine, is considered the ancestor of the counterweight forklift. In 1928, many features were combined to create a completely new car. The landing gear (frame) of the Duat prototype is used as the basis for the forklift, which has a hydraulic lifting system, front-drive wheels, rear-wheel steering, rubber tires, and a counterweight. The new machine is called a tractor. About a year later, the prototype was fitted with a gantry and tilt mechanism. Soon after, the name Tructractor changed to Trucker. Front-wheel drive and rear-wheel control systems are installed on the TRUCTIER-A model. The TRUCKER-B has a rear-wheel drive and front-wheel control system. On some Tructier-B models, retractable lifts have been installed, marking a milestone in the development of a new generation of forklifts. Over the next few years, the company began producing the famous Clark Gearbox. As a result, the company developed a basic design philosophy, and its name itself became a symbol of the forklift.

By the beginning of the Second World War, Cluck was recognized as a market leader. At least 90 percent of all tractors and loaders (including forklifts) used by the U.S. military during the war were produced by the company. In 1942, the first electric forklift went off the line. This technology is beginning to appear in Europe. The first factory in Europe was built in 1952 in Milheim, Germany.

Eugene Cluck died in 1942, aged 60, of pneumonia, leaving behind a company with annual sales of $77m.

Clark's latest history in 1991, the United States began an industrial recession that led to a general decline in forklift production. Clark sold his transportation equipment business to Terex Corporation in 1992. In 1995,11 members of Clark's board of directors redeemed control of Trax. In 1998, Clark consolidated his position in the international market by acquiring the forklift unit of South Korean manufacturer Samsung. In January 2003, Young An (South Korea) acquired Clark Material Handling Company. Clark branch, USA. Young An is well known for making intercity buses, farm machinery and later real estate deals, and has expressed interest in acquiring the European arm of Clark material handling. But most of the company's employees turned down the deal with Young An. In April 2003, CMHE, the Cluck Material Handling Europe company founded by Phil Filipov, a former executive of TEREX Corporation, was declared bankrupt and sold along with FILCO's patents. The majority of FILCO's shares are held by Airtrax, an American company. Ownership of inventory, know-how, drawings and other information related to Cluck's parts business (better known as CCP or Cluck central parts) has been taken over by the TVH group (Belgium).

2. The history of forklift truck's geographical expansion

The history of forklift trucks can be traced back nearly a century and shows many interesting patterns. The main determinant, of course, is the economy: Every increase in fast demand and output for forklifts is driven by demand for industrial production while spurring technological innovation. The impact of political events can not be underestimated, the most typical examples being the first and Second World Wars. Another well-known fact is that investment in a particular sub-par. For example, the economic investments that Marshall planned to make after World War II to revive the European economy led to the rise of certain companies -- and the rise of manufacturers of moving equipment.

Similarly, the most obvious is the impact of technological innovation on economic growth. The widespread use of forklifts has reduced the proportion of manual labor in the production and warehousing processes. Each of these has had a positive effect on the increase in Labour productivity and the increase in the production of goods. Therefore, the development of the forklift itself has become a factor in the gradual development of the economy.

First Clark loader, 1917

The first European forklift (IPSWICH'S RANSOMS & Rapier) was fitted with electric drives and cable masts

In fact, the history of this particular worker-from his birth to the present can be divided into several stages. The first has to do with America's economic boom and, more specifically, with the emergence of the first industrial companies in the United States. It was here, in the early 20th century, that the large-scale automobile industry (one of the main sources of ideas for loader designers), the rapid development of the aviation industry, the establishment of the railway network, which in turn led to the economic development of the city. The development of the seaport has also been a driving force for forklift manufacturers as it has facilitated the accumulation of experience in the design of cranes, winches and similar machines. Not surprisingly, it was the Americans who drove the development of forklifts. The first models were developed by companies like Clark, tractors, Heist, Baker, and Yale; some of them have so far had a major impact on shaping the flooring equipment market and setting its priorities.

The first loaders were mainly due to increased production and the need to handle a large number of heavy loads simultaneously. The direct ancestor of the industrial forklift was a machine for transporting sand and raw castings, created by a group of workers at Cluck's foundry. In fact, from 1916 to 1917, up to the 1940s, the United States was still the geographical center of forklift manufacturing. Europe mainly imports loaders from the United States, or manufactures them under American license, although European companies, for example, the then famous makers of a steam locomotive, cranes, and earthmoving machinery, ransoms & Rapier and Lansing Bagnal, also tried to make their own forklifts.

Ransoms produced the first tilting gantry forklift (circa 1920) and the first forward-moving forklift (1926)

Ransoms produced the first fork-lift truck with an inclined portal frame (circa 1920) and the first fork-lift truck with a forward displacement (1926)

As noted above, the next reference point in forklift history was the first World War. Army officers saw the ideal vehicle for transporting explosives in electric tricycle loaders. As you know, the inventor of the loader, Eugene B. Clark, got a priority order from the army to build a three-wheel loader. CLUCK assigned a separate production line and built the entire plant.

For Baker, a maker of electric cars, the company introduced the first electric forklift in 1920 to transport steel rims. World War I was a period of economic stagnation where production was suspended for a lack of raw materials. As a result, in Europe, the first locally produced forklifts were not mass-produced until 1923. The first information on electric forklifts came with the release of the KF202 model, which has a lifting capacity of 2 tons ("K" for "King", "F" (United Kingdom)-"France" (France)). The forklift was developed by Yale forklift, a unit of the North American Mining Group, but has been licensed by Fenwick in France since 1923. Interestingly, one of the earliest buyers was the French car company Citroen.

Circa 1932, Trucker (Clark), also known as Tiesto, had front-wheel drive, rear-wheel drive, inclined door frames, and hydraulic systems.

The Second World War provided a strong impetus for the development of forklift production, mainly in the United States. This fact is clearly confirmed by the use of forklifts by the United States military in carrying large quantities of munitions onboard ships. Here, forklifts are irreplaceable because the military needs to unload the entire fleet very quickly. Forklifts have even been used on US navy ships to remove debris from the take-off deck and dump it into the sea. The production of forklifts has increased dramatically, and the days of heavy manual labor are gone. Roughly 2,000 forklifts are removed from Clark's assembly line each month (compared with 50 to 75 before the war). During World War II, Clark supplied 90 percent of the forklifts involved the U.S. military economy. Yale and Hyser were also able to increase production at the time.

In 1939, a trailer transporter (in addition to the regular trolley for the long haul) was used.

After the end of hostilities in 1945, the United States military not only left operating forklifts in Europe but also in large numbers. All US manufacturers have signed export equipment supply contracts and appointed their European distributors and distributors. In Europe, forklifts began to really flourish. Another positive technological achievement of the Second World War was the new concept of "transport of goods and equipment". Carrying goods on BT Industries'so-called Euro Pallets (hand-held forklifts), coupled with new loading equipment, has saved millions of man-hours in the loading and unloading of ships, trains and freight trucks.

Carloader (Clark) was used in 90% of all forklifts related to the US economy during the Second World War.

In 1959, Japan's TCM (Toyo Carrier Manufacturing Co., Ltd.) and Komatsu delivered the first forklifts to Europe; Nissan's forklifts were delivered in 1965 and Toyota's in 1969. In general, it can be argued that the 1960s was the beginning of an "Asian forklift invasion" facing Europe. At the same time, Japanese manufacturers have a presence in Western markets, along with European, American and, to some extent, eastern European competitors. First, they offer products that are cheaper than those offered by European manufacturers, which started out with lower quality forklifts but then reached the same level of competition as European forklifts. In addition, the Japanese forklift as standard equipment into the European and American markets, while reducing market prices by 35%. In the 1980s, European forklift factories have launched a counteroffensive and are trying to restrict forklift imports from Asia by increasing imports to the continent and raising tariffs. The Japanese are quick to respond, starting with Toyota's own forklift production plant in Europe (Anseni, France), and soon other Japanese companies will follow suit: TCM (Bruges, Belgium), Almere (Netherlands), Nissan (Pamplona, Spain), Komatsu (first in the British Leighton Buzzard, then in Bary (Bari), Italy.

In 1976(at the forefront of advanced technology), the first Komatsu unmanned forklift came out.

Over time, Asia's boom coincided with a host of other problems for European manufacturers themselves. First, it's an energy crisis. In addition, these companies are increasingly influenced by environmental factors and the public is becoming increasingly aware of the need to protect the environment in this regard. Industrial Development, meanwhile, is facing a rapid increase in real estate prices (in the 1990s) due to a disastrous lack of land. Surprisingly, despite all this, manufacturers in both Europe and the United States have made no effort, even some attempts, to win at least some market share in Asia. This is partly explained by cultural differences and the remoteness of Asian markets. Cultural differences in consumer attitudes toward technology between Europe and Asia also play a role: three years later, Asia cut off some imports of used forklifts from Europe and began investing in new cars. They think European forklifts are too expensive and have been used for too long. There is another nuance: In the Asian market, the mechanical transmission is preferred, in Europe and the United States, they prefer an automatic transmission.

Since the late 1980s, South Korean forklift truck makers Daewoo, Hyundai and Samsung have opened factories and "broken into" the world market. The most famous of these is Daewoo, which has a good share of the global market.

Eastern European manufacturers have also played a minor role in the world history of forklift development. Well-known brands in Eastern Europe include V. T. A. Kraft (ex-east Germany), Desta (ex-Czechoslovakia), Lviv (Ukraine) and Balkancer (Bulgaria). These manufacturers are in effect monopolists among the members of the Committee on Mutual Economic Assistance, which includes Cuba, Vietnam, and Mongolia. But in other European countries, their products are almost impossible to find. The difficulty of exporting to Western Europe is related to the fact that forklifts in eastern Europe have to be re-engineered and brought to the lowest level of quality commensurate with the requirements of customers in western Europe. Another obstacle for Western importers is the long wait for supplies of forklift parts in eastern Europe. Thus, in the best years of operation, Balkancer produced 100,000 forklifts per year for the Eastern European market. After Perestroika, the market opened up for Asian brands. Initially, customers in Eastern Europe could not afford to buy new forklifts, so they had to buy used ones, while Western companies integrating into Eastern Europe brought their own favorite forklift brands. By 2003, sales of Balkancers had fallen sharply.

We believe that there are some impressive figures that need to be corrected, namely that Eastern European manufacturers have not played an important role in the development of global forklift history. Finally, we must pay tribute to the concerns of Balkancer forklifts, because even Toyota and Linde, the world's top forklift manufacturers by far, could not produce as many forklifts a year at the time, and if the Soviet Union and the CMEA don't fall apart, it's hard to say who will be the current world leader in forklift COMECON.

Hyster forklift looks back at its history in this unusual exhibition at Cemat 2005. CEMAT, founded in 1936, is one of the most famous logistics exhibitions in European history.

It is hard to say when local companies will be able to restore a large enough capacity for forklifts. However, it should be noted that some manufacturers from Bulgaria are still thriving. Examples include DIMEX, Sparky, Herkulift, and others.

Today, in the world market for material handling equipment, economic integration has led to the exchange of shares and acquisitions between small forklift manufacturers and large companies. For several years, the top 10 leaders have included Toyota, Linde, Jungheinrich, NACCO Industries, Crown, Mitsubishi Caterpillar, Komatsu, Nissan, TCM, Nissan, Nichiyu. Wait for the company. Another clear trend is the transfer of some or all of the production capacity to the territories of Asian countries, mainly China. Almost all of the world's major industrial vehicle manufacturers already have branches in China. Finally, the forklift has been improved not only in function but also in aesthetics. Competition among manufacturers is increasingly centered on forklift truck design, which includes customization, unique functionality, and ergonomics and environmental friendliness.

Whatsapp me or call me via +86 17131089938

Email: edward@unforklift.com

Whatsapp: +86 17131089938

Company web: www.unforklift.com

Manejo de materiales

4yvery good, thanks for informartion.