Light Vehicle Inspection Manual (PDF 7MB) - Transport

Light Vehicle Inspection Manual (PDF 7MB) - Transport

Light Vehicle Inspection Manual (PDF 7MB) - Transport

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

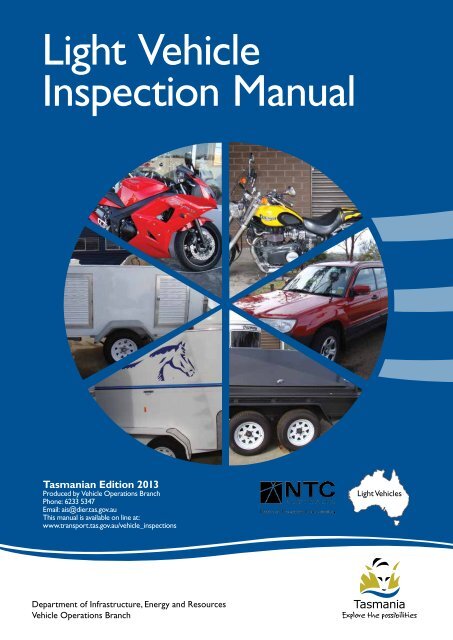

<strong>Light</strong> <strong>Vehicle</strong><strong>Inspection</strong> <strong>Manual</strong>Tasmanian Edition 2013Produced by <strong>Vehicle</strong> Operations BranchPhone: 6233 5347Email: ais@dier.tas.gov.auThis manual is available on line at:www.transport.tas.gov.au/vehicle_inspections<strong>Light</strong> <strong>Vehicle</strong>sDepartment of Infrastructure, Energy and Resources<strong>Vehicle</strong> Operations Branch

Produced by<strong>Vehicle</strong> Operations BranchDepartment of Infrastructure,Energy and ResourcesGPO BOX 936Hobart Tasmania 7001Phone: 03 6166 3265Email: ais@dier.tas.gov.auThis manual is available online at:www.transport.tas.gov.au/vehicle_inspections2 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

ContentsVery Important Advice 9Administration of this <strong>Manual</strong> 11<strong>Light</strong> Motor <strong>Vehicle</strong> <strong>Inspection</strong> Checklist 12Section 1<strong>Vehicle</strong> Identification 151.1 Check the identity of the <strong>Vehicle</strong> 15Section 2Brakes 172.1 Check the operation of the brake controls 172.2 Inspect the condition of visible brake components 182.3 Brake testing with a roller brake tester 19Section 3Towing Attachments 213.1 Visually inspect the towbar and its mounting on the vehicle body 21Section 4Steering and Suspension 234.1 With the engine running, check the operation of the steering bymoving the steering wheel, or, on cycle type vehicles, the handle 234.2 Visually inspect all steering components under the bonnet andunder the vehicle 244.3 Examine the idler arm 244.4 Visually inspect the suspension 24Section 5Wheels and Tyres 275.1 Visually inspect the inside and outside of each road wheel 275.2 Visually inspect each road tyre 275.3 Tyres on four wheel drive/off road vehicles 285.4 Measure the wheel track, where modified from standard, takingmeasurement from the centre of the tyres 28Section 6Body Condition 296.1 Check the operation of all doors, door locks and latches and thebonnet lock and latches 296.2 Visually inspect the windscreen and front side windows 296.3 Test the light transmittance level of the windscreen, side andrear windows 30<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 3

6.4 Visually inspect body panels, chassis and sub frame for dangerousprotrusions and rust 316.5 Dimensions 326.6 Rear overhang 326.7 Inspect the wheel arches/mudguards and mudflaps, with the wheelsin the “straight ahead” position 326.8 Visually inspect rear vision mirrors 336.9 Visually inspect and check the operation of the windscreenwipers and windscreen washers 336.10 Check the operation of the horn 336.11 Visually inspect the front and rear number plates 336.12 Where ADR25 applies, check the operation of the anti-theft/steering lock 346.13 Where ADR42 applies, check the operation of the windscreen demister 346.14 Speedometer 34Section 7Seats and Seatbelts 357.1 Check seats. 357.2 Check the operation of seats, seat belts, buckles and other restraints,and inspect webbing and metal stalks 35Section 8<strong>Light</strong>ing 378.1 Visually inspect the compulsory reflectors fitted to the rearof the vehicle 378.2 Visually inspect and check the operation of all lights fitted to the vehicle 378.3 Visually inspect and check condition of all lights fitted to the vehicle 398.4 Visually inspect and check light switch operation 398.5 Visually inspect front and rear lights for the presence of tinted covers 398.6 Using a headlight tester, check the aim of the headlights 398.7 Visually inspect the headlights 40Section 9Engine Compartment & Driveline 419.1 Visually inspect the engine, transmission and driveline for oil leaks 419.2 Visually inspect engine, transmission and driveline components 419.3 Visually inspect the electrical system 419.4 Visually inspect the exhaust system 429.5 Visually inspect the fuel system 429.6 Where it is evident that a vehicle is emitting significantly higherexhaust noise than normal, conduct a stationary noise test 43Section 10Fuel Systems LPG/LNG/CNG <strong>Vehicle</strong>s 4510.1 Visually inspect for the presence of an approved LPG/LNG/CNGmodification plate and number plate labels. 4510.2 Visually inspect the LPG/LNG or CNG container 4610.3 Visually inspect the container anchorages and straps 4710.4 Visually inspect remote filled internally mounted containers 484 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

10.5 Visually inspect direct filled internally mounted containers 4810.6 Visually inspect externally mounted containers 4810.7 Visually inspect ullage and safety valves 4910.8 Visually inspect hydrostatic relief valves 4910.9 Visually inspect fuel lines, joints and connections 4910.10 Visually inspect shut off devices, converters (vaporiser regulators),fuel selectors and air/gas mixers. 4910.11 Visually inspect the lpg electrical wiring 5010.12 Test the operation of the fuel containment system 50Section 11Petrol/Diesel <strong>Vehicle</strong>s 5111.1 Visually inspect the fuel system 5111.2 Visually inspect fire extinguisher (where required eg omnibuses,caravans and tow trucks) 51Section 12Motorcycles 5312.1 Visually inspect the condition of the brake controls 5312.2 Check the operation of the brake controls 5312.3 Inspect the condition of visible brake components 5312.4 Check the operation of the parking brake on ADR 33 cycles fittedwith side-car outfits and motor tricycles 5412.5 Visually inspect the towbar and its mounting to the frame 5412.6 Visually inspect all steering components 5512.7 Visually inspect the suspension 5512.8 Inspect both sides of each road wheel 5612.9 Visually inspect each road tyre 5612.10 Visually inspect body panels, chassis and frame for dangerousprotrusions and rust 5712.11 Inspect the mudguards 5712.12 Seating 5712.13 Visually inspect rear vision mirror(s) 5712.14 Check the operation of the horn 5812.15 Visually inspect any exposed drive chain or belt or shaft 5812.16 Visually inspect the number plate 5812.17 Visually inspect the compulsory reflectors fitted to the rear of the cycle 5812.18 Visually inspect and check the operation of all lights fitted to the cycle 5812.19 Inspect electrical control switches 5912.20 Visually inspect front and rear lights for the presence of tinted covers 5912.21 Using a headlight tester, check the aim of the headlight(s) 6012.22 Visually inspect the headlight(s) 6012.23 Visually inspect the engine, remote oil reservoirs, transmissionand driveline 6012.24 Visually inspect the fuel system 6012.25 Visually inspect the exhaust system 6112.26 Where it is evident that a motorcycle is emitting significantly higherexhaust noise than normal, conduct a stationary noise test inaccordance with Appendix B 61<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 5

Section 13Motor Homes 6313.1 Visually inspect the living quarters 63Section 14<strong>Light</strong> Trailers & Caravans 6514.1 Inspect the trailer for brake requirements 6514.2 Inspect the condition of visible brake components 6514.3 Brake testing of trailers fitted with override brakes 6514.4 Brake testing of trailers fitted with brakes other than override brakes 6514.5 Where fitted, test the parking brake 6614.6 Where fitted, inspect the emergency braking system/brake awaybraking system 6614.7 Visually inspect the trailer coupling, drawbar and mountings onthe trailer body 6614.8 Visually inspect safety chains or ropes 6714.9 Visually inspect all suspension components 6714.10 Visually inspect the inside and outside of each road wheel 6814.11 Visually inspect each road tyre 6814.12 Check Wheel bearings 6814.13 Check the operation of doors, gates and flap 6814.14 Visually inspect body panels, chassis and frame 6814.15 Inspect the mudguards 6914.16 Visually inspect the number plate 6914.17 Visually inspect mandatory reflectors 6914.18 Visually inspect and check the operation of all lights fitted to the vehicle 7014.19 Rear overhang 7114.20 Dimensions 7114.21 Visually inspect the livng area of a caravan 71Section 15<strong>Light</strong> <strong>Vehicle</strong> Standards – Specific to Taxis 7315.1 <strong>Vehicle</strong> Suitability 7315.2 Visually Inspect Taxi Meter, 2 Way Radio, (Including Radio DispatchVisual Display Units) and Internal Tariff Indicators 7315.3 Visually Inspect External Indicators 7415.4 Visually Inspect Security Camera System 7515.5 Visually Inspect the Outside Doors 7515.6 Visually Inspect Inside the <strong>Vehicle</strong>s 7515.7 Additional Security Cameras Installed (Optional) 7615.8 Wheelchair Accessible Taxis (WAT) 7615.9 Restricted Hire <strong>Vehicle</strong> - General 77Section 16<strong>Light</strong> <strong>Vehicle</strong> Standards - Specific to Driving Instructor <strong>Vehicle</strong>s 7916.1 Visually inspect the <strong>Vehicle</strong>s Dual Controls 796 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

8 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Very Important AdviceThe purpose of this manual is to provide information on the minimum roadworthiness and safety standards for vehiclesused on Tasmanian roads.Every effort has been made to provide comprehensive advice, however this manual cannot cover all eventualities,especially in the case of non-standard and modified vehicles.If you think a vehicle is deficient or has a safety defect of any sort which is not covered in this manual please seek advicefrom the Department of Infrastructure, Energy and Resources by phone on 62335214, or email transport@dier.tas.gov.au<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 9

10 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Administration of this <strong>Manual</strong>Important InformationThis manual has been checked and is believed to be correct at the time it was released. The version number and releasedate is shown on the bottom of each page.The applicable legislation takes precedence over the contents of this manual and in the unlikely event there is a discrepancyin the information provided, the legislation will always prevail.CustodianThis manual is administered and maintained by:Manager, <strong>Vehicle</strong> Standards<strong>Vehicle</strong> Operations BranchLand <strong>Transport</strong> Safety DivisionDepartment of Infrastructure Energy and ResourcesGPO Box 935 Hobart Tasmania 7001Publication and DisseminationThis manual may be downloaded from the Department of Infrastructure, Energy and Resource’s website atwww.transport.tas.gov.auVersion ControlThis version supersedes and takes precedence over the previous version, which was released in June 2013.Suggestions for ImprovementThis manual is a “live document” that will require revision from time to time to include improvements in vehicle technologyand to accommodate changes in the legislation etc. Suggestions for improvements and notification of any corrections arewelcomed, please phone (03) 6233 5314, email ais@dier.tas.gov.au or fax (03) 6233 5210.EnquiriesTechnical enquiriesMay be made by phoning (03) 6166 3263Administration enquiriesMay be made to the Manager, <strong>Vehicle</strong> Standards, Accreditation/AIS Compliance, email ais@dier.tas.gov.au orphone (03) 6166 3263<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 11

Tasmanian <strong>Inspection</strong> <strong>Manual</strong> for <strong>Light</strong> <strong>Vehicle</strong>s<strong>Light</strong> Motor <strong>Vehicle</strong> <strong>Inspection</strong> Checklist<strong>Light</strong> Motor <strong>Vehicle</strong> <strong>Inspection</strong> Checklist1. IDENTITY Mountings 13. ENGINE & DRIVELINE Compliance Plate Locking/snatch test Mountings VIN/Chassis No 8. UNDER BONNET CHECK Oil leaks Engine No Master Cylinder Universal joints2. ELECTRICALCHECK Headlight/parklights Headlightalignment Engine oil leaks Engine fuel leaks Air Cleaner Centre bearing14. EXHAUST Exhaust leaks Tail lights Engine mountings Mountings Indicators Exhaust system Clearance–hoses/wiring Brake lights Battery security Catalytic Converter Reverse lights Wiring security 15. REAR SUSPENSION Reflectors Steering shaft Control arms Lens condition Steering coupling Bushes Windscreen wipers Power steering leaks Ball joints Windscreenwashers9. STEERING Springs/shock absorbers Horn Steering box Bump stops3. BODY CHECK Steering rack Modifications Rust Linkages Suspension height Protrusions Tie rod ends 16. WHEELS & TYRES REAR Bonnet safetycatch Idler arm Condition Windows 10. FRONT SUSPENSION Tread pattern Windowtint % Control arms Tyre speed rating4. INSIDE CHECKS Bushes Tyre load rating Heater/demister Ball joints Rims Heater fan Springs/shock absorbers After market tyres/rims ABS/SRS lights Bump stops Wheel track: Pedal condition Modifications 17. FUELTANK Brake pedal height Handbrakeoperation Suspensionheight…..mm11.WHEELS &TYRESFRONT Mounting Conditionmm12 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013Version 4 – 1 May 2009 Page 10

Inhibitor switch(auto) ConditionTasmanian <strong>Inspection</strong> <strong>Manual</strong> for <strong>Light</strong> <strong>Vehicle</strong>s Fuel leaks Steering wheel Tread pattern Fuel line Steering wheelfreeplay Tyre speed rating18. LPG GAS Window operation Tyre load rating Gas compliance certificate Door operation Rims 19. BODY & FRAME5. MIRRORS After market tyres/rims Rust ConditionWheel trackmm Cracks Mountings 12. BRAKES Bends/kinks6. SEATS Pipes and hoses Modifications Condition Discs and drums Mudguards Adjustments Fluid leaks 20 CAMPERVAN Mountings Caliper/hose security Gas/electrical compliance7. SEAT BELTS Pads and linings Fire extinguisher Condition Linkages 2 nd stage manufacture plate ComplianceMOTORCYCLE Security/noise1. IDENTITY 9. BODY & FRAME CHECK Compliance Plate Fuel tank VIN/Chassis No Seat/s/condition/mounting Engine No Mudguards2. ELECTRICAL CHECK Bends/kinks/cracks/rust Headlight/park lights Modifications Headlight alignment Tail lights Indicators Brake lights Reflectors Lens conditions Horn Battery securityLIGHT TRAILER/CARAVAN10. IDENTITY Compliance Plate VIN/Chassis No Unladen mass GTM11. DRAW BAR Master cylinder/Brake away3. HANDLEBARS Pipes and hoses Mirrors Linkages Throttle return Tow coupling Clutch lever Safety chain<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 13Version 4 – 1 May 2009 Page 11

Tasmanian <strong>Inspection</strong> <strong>Manual</strong> for <strong>Light</strong> <strong>Vehicle</strong>s Handlebar security Draw bar Hand grips12. ELECTRICAL CHECKS4. BRAKES Tail lights Master cylinder/s Indicators Pipes and hoses Brake lights Discs and drums Side clearance lights Fluid leaks Reflectors Caliper/hose security Lens conditions Pads and linings13. SUSPENSION Linkages Wheel bearings5.SUSPENSION Springs Front forks and braces Shackles Shock absorbers Axle Springs14. BRAKES Swing arm bushesPipes/hoses/leaks Axle location and lock nuts Pads/linings Drive chain/belt/ and cover Drums/caliper6. ENGINE 15. WHEELS &TYRES Oil/fuel leaks Condition Mountings Tread pattern Sprocket/pulley cover Rims Air filters16. BODY & FRAME CHECK Fuel lines Rust Gear lever Cracks7. WHEELS &TYRES Bends/kinks Condition Modifications Tread pattern Mudguards Rims Gas compliance8. EXHAUST Electrical compliance Exhaust leaks Fire extinguisherVersion 4 – 1 May 2009 Page 1214 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Section 1:<strong>Vehicle</strong> IdentificationAustralian Design Rules relevant to this section:ADR 61/00. /01. /02 <strong>Vehicle</strong> MarkingsOBJECTIVE: To ensure that vehicle being inspected is authentic and correctly identified.1.1 Check the identity of the vehicleReason for Rejectiona) No VIN/Chassis number present.b) VIN/Chassis on compliance plate differs from that stamped into body or chassis.c) VIN/Chassis number has been altered or tampered with or not authentic.d) Engine number has been altered or tampered with.e) No engine number present.f) A motor vehicle other than a motor- cycle, manufactured after August 1972 that is not fitted with an Australiancompliance plate and has not been previously registered in Australia.g) A motor- cycle manufactured after June 1975 that is not fitted with an Australian compliance plate and has notbeen previously registered in Australia.h) A trailer manufactured after December 1988 that is not fitted with an Australian compliance plate and has notbeen previously registered in Australia. *i) <strong>Vehicle</strong> manufactured prior to August 1972 that has not been previously registered in Australia.Note: An AIS may pass a new (not previously registered) light trailer for registration when it has been inspected and found to beroadworthy by obtaining a VIN and fitting a recognised compliance plate in accordance with procedures set out in the AISmanual.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 15

16 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Section 2:BrakesAustralian Design Rules relevant to this section:ADR 31 Hydraulic brake systems for passenger carsADR 33 Brake Systems for Motor CyclesADR 35 Commercial vehicle brake systemsADR 38 Trailer brake systemsADR 42 General Safety RequirementsOBJECTIVE: To ensure that the brakes operate effectively and are correctly adjusted.2.1 Check the operation of the brake controlsReasons for rejectiona) on rubber faced brake pedals, any metal is showing.b) on metal brake pedals, there is no anti-slip surface.c) missing or broken brake pedal or handle, or associated components.d) brake pedals or handles are broken or missing or are outside the scope of manufacturer’s original design.e) when the service brakes are firmly applied, less than 20% of the pedal travel remains (unless withinmanufacturer’s limits).f) when steady moderate pressure is applied to the service brake pedal for 10 seconds, the pedal travels towardsthe floor or the brake failure indicator light comes on.g) where ADR 31 or 35 applies, the brake failure warning light does not operate when the ignition is turned “on”,before the engine is started.h) Any park brake handle or control lever is not fitted with a locking device capable of holding in any position.i) When not in use, any brake lever, handle or pedal does not return to the fully released position.j) where ADR 31 applies, the park brake warning lamp does not operate when the ignition is “on” and the parkingbrake is applied.k) The brake controls, when operated, do not cause the corresponding brake to operate (with the engine running, ifnecessary).l) Where a vehicle manufactured after 1 July 1988 is fitted with an “antilock system” (ABS) the antilockwarning lamp doesn’t illuminate when; the ignition is switched to the on position; and the antilock warning lampextinguish after the static check period or the vehicle reaches 10 km/h.m) Where a vehicle manufactured after 1 Nov 2011 that is fitted with an Electronic Stability Control system (ESC),the ESC malfunction tell-tale lamp doesn’t:1. Illuminate when the ignition is switched to the on position; and2. Extinguish after the check period; and3. Illuminate with the word “OFF” below the ESC symbol when the ESC is switched off.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 17

2.2 Inspect the condition of visible brake componentsNOTE:This includes the area underneath the vehicle.Reason for rejectionNOTE:a) Brake pipes, hoses and connections are damaged, severely deteriorated, not securely mounted, cracked, broken,kinked, crimped, damaged by heat or have visible signs of leakage, swelling or bulging (See Note1).For example the reinforcement fabric is exposed or the hose swells or bulges when the brakes are applied. Minorcracking or splits in the outer casing are not a reason for rejection but should be brought to the attention of the owner).b) where visible, any brake component is broken, excessively worn, leaking, contaminated or is not securelymounted.NOTE: Use manufacturer’s limits for assessing wear in componentsc) any hydraulic brake hose is of insufficient length to allow for the full range of steering and suspension movement,or is twisted.d) hydraulic lines are not constructed of approved material. (See note 2).e) any braided hydraulic brake hose that is not marked with the manufacturers name and compliance with a SAA,SAE, BS, JIS, DIN, ISO or ECE standards for flexible brake hoses.f) hydraulic pipes or hoses are not manufactured, repaired and marked to relevant Australian Standards (orequivalent). (See Note 3).g) hydraulic pipes are repaired by heating or welding (See Note 4).h) the level of brake fluid is below the minimum indicated level.i) where visible, the brake lining material, at any point, is worn to less than manufacturers limits or if the limits arenot known ;0.8mm above bonded shoe or pad mounting surface and level with the rivet or bolt heads on rivetedor bolted linings.j) it is evident that any power/vacuum assistance for the brakes is not operating or compressors, vacuum pumps,pulley belts are loose, cracked or worn.k) evidence of brake fluid leaking from any component, joint or seal.Note 2: The use of copper pipe for hydraulic brake pipe is not allowedTasmanian <strong>Inspection</strong> <strong>Manual</strong> for <strong>Light</strong> <strong>Vehicle</strong>sThe use of copper pipe for hydraulic brake pipe is not allowedHydraulic Brake Hoses fitted to vehicles that are required to comply withl) where ADR 42 applies, any brake hose is not marked with manufacturers name.ADR 7, 7/00 or 42/04 should be manufactured to SAE J1401 orNote 1: Threaded bosses used braking component mounting must have full depth thread engagement of at least the boltequivalent. Flares for Tubing should be in accordance with SAE J5336diameter.or equivalent.Note 3: Hydraulic Brake Hoses fitted to vehicles that are required to comply with ADR 7, 7/00 or 42/04 should bemanufactured to SAE J1401 or equivalent. Flares for Tubing should be in accordance with SAE J5336 or equivalent.Joining hydraulic brake pipes by brazing, silver soldering, etc. is notallowed. Note 4: Joining hydraulic brake pipes by brazing, silver soldering, etc. is not allowed.Figure 2 1 : Drum brake componentsDisc brake componentsigure 2-1 : Drum brake componentsDisc brake components18 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

2.3 Brake testing with a roller brake testerNOTE:This section should be read in conjunction with the equipment manufacturer’s instructionsUsing a roller brake tester, check the retardation forces on each wheel. Release all brakes, place transmission in “neutral”(not “park” for automatic transmission) and slowly apply a braking force until a maximum force is attained, or wheel slipoccurs.Reasons for rejectiona) there is more than 30% difference in the brake force between the wheels on any axle.b) the minimum brake force on any wheel is less than the performance requirement specified in Table 2.1.c) with the brakes released, the average brake drag is more than the performance requirement specified inTable 2.2.d) the parking brake does not give a reading, or the vehicle does not lift out of the roller.TYPE OF VEHICLEkN (minimum)Less thn 2.5 tonnes tare* 2.02.5 tonnes or over 3.0Table 2.1 : Minimum Brake ForceTYPE OF VEHICLELess thn 2.5 tonnes tarekN (minimum)0.5 drive axle0.25 other axle2.5 tonnes or over 1.0 drive axle0.5 other axleTable 2.2 : Maximum Brake DragNOTE:NOTE:On some light vehicles the brake force limit might not be reached as the vehicle will be lifted out of the rollers. Similarly,it might not be reached if a load proportioning valve is fitted to the rear axle. In both cases it is considered a pass if thebrake balance is within the specified limit.For further information on Brakes, refer to Appendix A ‘Brake drums and Discs’<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 19

20 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Section 3:Towing AttachmentsAustralian Design Rules relevant to this section:ADR 42 General safety requirementsADR 62 Mechanical connections between vehiclesOBJECTIVE: To ensure that all tow couplings and associated components are in a serviceable condition and that they providethe necessary load carrying capacity.3.1 Visually inspect the drawbar and its mounting on thevehicle bodyReasons for rejectiona) any towing attachment fitted to a vehicle, is not operational, not secure, or cracked, excessively worn, deformedor damaged in a way likely to cause failure.b) Tow bars, tow hooks, automatic pin type couplings and their attachments, if fitted to a vehicle, are not operational,not secure, or are cracked, excessively worn, deformed or damaged in a way likely to cause failure.c) any mounting bolts, fasteners or weld beads have advanced corrosion or are missing.d) where ADR 62 applies (vehicles manufactured after 1st July 1991), the towbar does not display the “name” or“trademark” of the manufacturer, the “make” and “model” shown on the identity plate of the vehicle for whichthe towbar is designed, and the towbars “maximum rated capacity”. (The “maximum rated capacity” must be the“ATM” in tonnes or maximum “coupling ‘D-value’ in kN for which the towbar is designed and must not exceedthe vehicle manufacturers rated towing capacity.e) where any part of the coupling or towbar is removable, the bolts, studs, nuts etc, fastening those parts do nothave a locking device such as a U-clip, split pin, spring washer, or nylon lock nut.f) Tow coupling tongue assemblies are not securely mounted to the tow bar assembly.g) The tow ball (if fitted) is not secure, is cracked or is excessively worn.h) The tow ball assembly (50 mm type) is not legibly and indelibly marked with the mark “50“ in characters not lessthan 5 mm high. (See Note 1).i) Safety chain/s or cables are not able to be connected or affixed in such a way that the safety chains/cables are notliable to accidental disconnection and are not readily detachable from the towing vehicle.j) Safety chain attachments are not affixed to a part of the towbar that is permanently attached to the vehicle.k) All electrical wiring, connectors, couplings, flexible pipes etc. associated with a device for coupling a trailer to amotor vehicle are not securely mounted and operational.l) A bicycle rack is fitted to the towbar and bicycles are not being carried.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 21

NOTES:(1) A 50 mm ball coupling is, generally, not acceptable for trailers which have an Aggregate Trailer Mass (ATM) in excess of2.3 tonnes.However, 50 mm ball couplings meeting the requirements of AS 4277.3 (Caravan and light trailer towing components -50 mm tow balls) are suitable for motor vehicles towing very light and light trailers of up to 3.5 tonnes ATM.Aggregate Trailer Mass (ATM) is the total mass of the laden trailer when carrying the maximum load recommended bythe manufacturer. This includes any mass imposed onto the drawing vehicle when the combination vehicle is resting on ahorizontal supporting plane.Note:For further information on Safety Chains, refer to Appendix B’ Safety chains for trailers.’22 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Section 4:Steering and SuspensionAustralian Design Rules relevant to this section:ADR 10 Steering ColumnADR 42 General Safety RequirementsADR 43 <strong>Vehicle</strong> Configuration and DimensionsADR 69 Full Frontal Occupant ProtectionOBJECTIVE: To ensure that the steering and suspension is in good working order and allows the driver effective control ofthe vehicle.NOTE:To be registered in Australia a vehicle must usually have a steering control (right hand drive) to the right of, or inline with, the centreline of the vehicle. <strong>Vehicle</strong>s which are over 30 years of age may have left-hand-drive subject tocompliance with certain conditions.4.1 With the engine running, check the operation of thesteering by moving the steering wheel, or, on cycletype vehicles, the handleReasons for rejectiona) where a steering wheel is fitted, there is more than 50mm rotational free play.b) the steering wheel is not free from structural damage.c) Accessories fitted to steering wheels (padded hubs, covers etc.) are loose.d) Steering controls on a vehicle that was manufactured less than 30 years ago are to the left of (left hand drive)centre line of vehicle.e) Steering wheels fitted to light passenger vehicles manufactured on or after 1 January 1971 are not replaced by asteering wheel which complies with Australian Design Rule No. 10 .f) the steering wheel is not securely attached to the steering column.g) where steering linkages are fitted to cycle type vehicles, the rotational free play exceeds 10mm measured at theend of the handle bars.h) where ADR 69 applies, the steering wheel is not of the same specification as the one provided by the vehiclemanufacturer.i) where an supplementary restraint system (SRS) airbag is fitted, there is any evidence that an airbag or other SRSsystem is inoperative (check the indicator light, where fitted - this usually illuminates when the ignition is firstswitched “on” and extinguishes after the system passes a self-test).Note: The minimum diameter of any replacement steering wheel must not be less than 330mm. The replacement wheel mustbe designed in a similar manner to the original (e.g. padded centre hub and dished spokes).<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 23

4.2 Visually inspect all steering components under thebonnet and under the vehicleNOTE:Take care with spring-loaded and rubber-bush joints. These components might be designed to have a certain amount ofallowable movement.Reasons for rejectionNOTE:a) any steering component is missing, cracked or broken or is worn beyond manufacturer’s limits.b) any steering component can be seen to have been repaired or modified by bending, heating or welding.Does not apply where an original component has been fitted by the manufacturer or repairs have been conducted tomanufacturer’s specifications.c) any nut, bolt or locking device is missing or insecure.d) Tie rod and drag link ends are not secured in both the rod and taper with fasteners suitably locked (e.g. split pins,lock-wire, tabs or self locking nuts).e) there is any movement on the spline between Pitman arm and the steering box or between any thread or taperedjoint.f) free play due to wear in any steering component exceeds manufacturer’s specification (if that specification is notknown, free play exceeds 3mm).g) any power steering componentTasmanianis leaking,<strong>Inspection</strong>damaged<strong>Manual</strong>or inoperative);for <strong>Light</strong> <strong>Vehicle</strong>sh) any manual or power steering componentry that is not securely mounted and free from excessive side or endplay, roughness, or binding.4.3 Examine i) any the power idler steering arm belts are loose, broken, frayed, missing, or cracked through to reinforcing plies.If fitted, attempt to move the idler arm in the direction of the pivot axis.4.3 Examine the idler armReason for rejectionIf fitted, attempt to move the idler arm in the direction of the pivot axis.a) The play at the end of the idler arm exceeds 8mm.Reason for rejectiona) The play at the end of the idler arm exceeds 8mm.Figure Figure 44-114.4 Visually inspect the suspension4.4 Visually inspect the suspensionReasons for rejectionReasons fora)rejectionany suspension component is broken, insecure, cracked, cut, missing, oil soaked, or can be seen to have beena) repaired any suspension or modified by component heating bending is broken, or welding insecure, or is worn cracked, beyond cut, manufacturers’ limits.b) anymissing,shock absorberor canorbestrutseenis inoperative;to have beenor isrepairedleaking fluid.or modified byheating bending or welding or is worn beyond manufacturers'c) any shock absorber or strut is not securely mounted.limits;d) any nut, bolt or locking device is missing or not secure.b) any shock absorber or strut is inoperative; or is leaking fluide) with the wheels raised, the vertical free play of any wheel exceeds 3mm.c) any shock absorber or strut is not securely mounted;d) any nut, bolt or locking device is missing or not secure;24 <strong>Light</strong> <strong>Vehicle</strong> e) with <strong>Inspection</strong> the wheels <strong>Manual</strong> raised, the vertical free play of any wheel exceedsVersion 11, December 20133mm;

Note:Superficial crazing is acceptable on rubber bushes. This is oftend) any nut, bolt or locking device is missing or not secure;e) with the wheels raised, the vertical free play of any wheel exceeds3mm;Figure 4 2Figure 4-2Tasmanian <strong>Inspection</strong> <strong>Manual</strong> for <strong>Light</strong> <strong>Vehicle</strong>sNOTE: Manufacturers’ tolerances take precedence over specified free play measurements when performing these checks.NOTE: Manufacturers' tolerances take precedence over specified freef) f) with with play the the measurements wheels wheels raised, raised, the when free the play free performing of play the of wheel these measured wheel checks. measured at the rim at exceeds the 6mm in total or 3mm from anycomponent.rim exceeds 6mm in total or 3mm from any component;Version 4 – 1 May 2009 Page 23Figure 4-3 4 3NOTE:Manufacturers’ Manufacturers' tolerances tolerances take precedence take precedence over specified over free specified play measurements free when performing these checks.g)g)anyplayaxlemeasurementscomponent, U-Bolt,whenspringperforminghangers, centretheseboltchecks.etc associated with the axle installation or performance iscracked, any axle loose, component, broken, missing U-Bolt, or worn spring outside hangers, of manufacturers centre bolt safe etc working limits.h) nuts associated do not fully with engage the axle the U installation Bolt thread. or performance is cracked,i)loose, broken, missing or worn outside of manufacturers safeany springs are cracked, broken, missing, displaced more than 10% of their width or in contact with wheels, brakesor working the frame. limits;j) h) air nuts bags do leak. not fully engage the U Bolt thread;k) i) any any raising/lowering springs are cracked, of eyebrow broken, height that missing, exceeds displaced 50mm from more original than manufacturer’s height.l)10% of their width or in contact with wheels, brakes or the frame;suspension heights are lowered or raised by more than one-third of the manufacturer’s bump stop clearance.m) j) A air vehicle bags does leak; not have a ground clearance equal to or more than:• k) 100 any mm raising within of one suspension metre of an that axle, exceeds and 50mm from original•manufacturer’s height;One thirtieth of the distance between the centres of adjacent axles at a midway point between them.l) suspension heights are lowered or raised by more than one-thirdNOTE: When measuring ground clearance, Tasmanian tyres, wheels and <strong>Inspection</strong> wheel hubs are <strong>Manual</strong> not taken into for consideration. <strong>Light</strong> <strong>Vehicle</strong>sof the manufacturer’s bump stop clearance;Note: Any suspension height modifications must comply with conditions set out in the National Code of Practice for <strong>Light</strong>m) A vehicle does not have a ground clearance equal to or more than:vehicle Construction and Modification – Section LS Tyres, Rims, Suspension and Steering.• 100 mm within one metre of an axle, and.• One thirtieth of the distance between the centres ofadjacent axles at a midway point between themNOTE:When measuring ground clearance, tyres, wheels and wheel hubsare not taken into consideration.Note:Figure 4 4 : Axle locating devicesAny suspension height modifications must comply with conditions set outNote: in the Superficial National crazing Code is of acceptable Practice on for rubber <strong>Light</strong> bushes. vehicle This Construction is often present and on rubber suspension components even when new.Modification – Section LS Tyres, Rims, Suspension and Steering.Note: For further information on Suspension, refer to Appendix C’ Suspension Modifications ’and Appendix D ‘Lift Kits’ andAppendix E ‘Ground clearances.’Figure <strong>Light</strong> <strong>Vehicle</strong> 4-4 : <strong>Inspection</strong> Axle locating <strong>Manual</strong> devicesVersion 11, December 2013 25

26 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Section 5:Wheels and TyresAustralian Design Rules relevant to this section:ADR 23 Passenger Car TyresADR 42 General SafetyOBJECTIVE: To ensure that road wheels and tyres are of a suitable type and condition and that they provide the necessaryload carrying capacity, speed rating and control of the vehicle.5.1 Visually inspect the inside and outside of each roadwheelReasons for rejectiona) any wheel or rim is cracked, has pieces of casting missing, or is buckled, shows signs of welding; signs of elongationof stud holes or redrilling of stud holes.b) the wheel nut must have a thread engagement length at least equal to the thread diameter or the fitting of thewheel nut does not match the taper of the wheel stud hole).c) any hub has missing or broken wheel mounting nuts, studs or bolts.d) any spoked wheel has any missing, loose, broken, bent or cracked spokes.e) the tyre or rim makes contact with or fouls any component at any point over the full range of suspension travelor steering movement.f) Wheels/rims are not of an approved type and construction.g) Spacer plates are used between hub and wheels, except where fitted by the vehicle manufacturer.5.2 Visually inspect each road tyreReasons for rejectiona) Any road tyre fitted to the vehicle is not a pneumatic tyre.b) the tyre has less than 1.5mm tread depth in a continuous band around the circumference on the surfaces whichnormally contacts the road.c) the tyre has deep cuts, bulges, exposed cords or other signs of carcass failure on either the side wall or treadsurface.d) tyres fitted to rims on an axle or axle group are not the same size.e) tyres are not compatible with the rim to which they are fitted and not of a type suitable for normal road use(space-saver wheels excepted).f) the tyre has been re-grooved (except where indicated on the sidewall that the tyres are suitable for re-grooving).g) any retreaded tyre fitted to the vehicle is not marked with the name or identification of the retreader and speedrating of the tyre.h) dual tyres contact each other.i) tyre load ratings are less than the minimum ratings specified originally by the vehicle manufacturer.j) for a car or car derivative, the maximum tyre width is more than 1.3 times larger than the vehicle manufacturer’swidest optional tyre width (See Note 1).k) a tyre that exceeds the maximum width of the vehicle.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 27

l) for a passenger car with 4 or more wheels manufactured after 1972, the speed rating of all tyres, when firstmanufactured, is not at least 180 km/h unless a lower rating has been specified.m) for a passenger car, the tyre/s have a rolling diameter that is 15 mm larger or 26 mm smaller than that of any tyredesignated by the vehicle manufacturer for that model.n) for a off road passenger or commercial vehicle, the tyre/s have a rolling diameter that is 50 mm larger or 26 mmsmaller than that of any tyre designated by the vehicle manufacturer for that model.o) alteration of tyres that effect the correct operation of the speedometerp) A symmetrical (directional) tyre fitted to the vehicle in the wrong direction.Note 1: Where the manufacturer offers the option of a wider track measurement (e.g. where wider wheels are optional), themaximum allowable track will be the maximum wheel track offered by the manufacturer or the track of the standardvehicle plus 25 mm for a car or car derivative.Note 2: Retreads must comply with Australian Standards AS 1973-1993 for speed and construction5.3 Tyres on Four Wheel Drive/Off Road <strong>Vehicle</strong>s:Reasons for rejection:a) For an off-road passenger vehicle (four wheel drive) fitted with front and rear beam axles, the maximum tyrewidth is more than 1.5 times larger than the vehicle manufacturer’s widest optional tyre width.b) The tyre width of the narrowest tyre fitted to a vehicle is less than 70 percent of the width of the largest tyrefitted or less than the manufacturer’s narrowest optional tyre and rim as indicated on the manufacturer’s tyreplacard.c) Where wider wheels and tyres are fitted which comply with both legislative and the manufacturer’s specificationsor are approved by the manufacturer and protrude beyond the vehicles extremities, additional flared mudguardsare not fitted. (See Notes 1 and 2).d) For a vehicle with beam axles the wheel track is increased by more than 50 mm over the manufacturer’s standardtrack measurement or vehicles without a beam axle where the wheel track is increased by more than 25 mmover the manufacturers standard track measurement. (See Note 1).e) For a off road vehicle with 4 or more wheels manufactured after 1972, the speed rating of all the tyres when firstmanufactured is not at least 140 km/h, unless a lower rating has been specified.Note 1: Where the manufacturer offers the option of a wider track measurement (e.g. where wider wheels are optional), themaximum allowable track will be the maximum wheel track offered by the manufacturer or the track of the standardvehicle plus 25 mm, or 50 mm for an off-road or commercial vehicle, fitted with front and rear beam axles.Note 2: Maximum regulation dimensional limits must not be exceeded.5.4 Measure the wheel track, where modified fromstandard, taking measurement from the centre ofthe tyresReason for rejectiona) The vehicle manufacturer’s specified wheel track measurement for the vehicle is exceeded by more than is currentlyapproved by State/Territory for specific vehicle types.Note:For further information on retreaded tyres, refer to Appendix F ’Retreaded tyres.’28 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Section 6:Body ConditionADRs applicable to this section:ADR 2 Sliding door latches and hingesADR 10 Steering columnADR 11 Internal Sun visorADR 18 InstrumentationADR 21 Instrument panelADR 25 Anti-theft lockADR 29 Side door strengthADR 34 Child restraint anchorages and child restraint anchor fittingsADR 42 General safety requirementsADR 43 <strong>Vehicle</strong> configuration and dimensionsADR 69 Full Frontal Impact Occupant ProtectionOBJECTIVE: To ensure the vehicle body is free of protrusions, structurally sound and free from any defects or additionalfittings that are likely to increase the risk of bodily injury to any occupant and other road users.6.1 Check the operation of all doors, door locks andlatches and the bonnet lock and latchesReason for rejectiona) any inside or outside door latch, bonnet, tilt cab, boot lid, hatch and removable covers (including safety catches, asapplicable) are not securely fitted, mounted and operating correctly.b) Door fastenings, hinges, inside and outside door control handles (as applicable) are not fitted, secure and operatingcorrectly.c) any bonnet or similar panel which covers the engine, luggage space or battery compartment and which is forwardof the windscreen, does not have a device to secure the panel in the closed position.d) any bonnet or similar panel which opens from the front (that is, the hinges are at the back) and which, whenopened, would obstruct the driver’s view through the windscreen, does not have a primary and secondary securingdevice.e) any hinges, or slides for doors, tailgates, side gates, hatches or compartment covers are damaged or worn andlikely not to prevent load or passenger from falling off.6.2 Visually inspect the windscreen and front sidewindowsOBJECTIVE: To ensure that the windscreen, windows and associated components are in such a condition that the driverhas a clear field of vision at all times under the normal range of climatic conditions.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 29

Reason for rejectionNote:a) The area of windscreen from the centre of the vehicle in front of the driver has cracks or is deteriorated to theextent it that interferes with the driver’s view.b) The wiped area of the windscreen in front of and on the same side of the vehicle as the driver has.1) damage (such as scoring, sandblasting or severe discolouration) that interferes with the driver’s view.2) any bulls-eye or star fracture that exceeds 16 mm in diameter, or any two (2) of the following.i) hairline crack up to 30 mm long.ii) a crack from the edge of the windscreen up to 75 mm long.Grooves in windscreens that are designed specifically to clean the wiper blades are not regarded as damage unless theyaffect the driver’s view. Approved grooving is usually identified by the installer.c) Any cracks in a laminated windscreen penetrate more than one layer of glass or are more than 150 mm long.d) Any glazing used in any motor vehicle is not safety glass (except a caravan) and where ADR 8 applies, the glassdoes not display an identification mark or symbol.e) Tint films are not free of bubbles, scratches or other defects that significantly affect the driver’s vision.f) Glazing is loose in its frame or cracked to the extent that sharp edges are exposed.g) Glazing, other than the windscreen, that is necessary for the driver to see the road is discoloured, obscured, badlyscratched, sandblasted or fractured to the extent that it interferes with the driver’s view.h) Items that obscure the driver’s view are placed in Area A or the corresponding area on the other side of thewindscreen.i) At least half the number of windows must be capable of being opened or the vehicle must be provided with analternative method Tasmanian of ventilation. <strong>Inspection</strong> <strong>Manual</strong> for <strong>Light</strong> <strong>Vehicle</strong>sj) Windscreens are removed and not replaced.EXCEPTION: EXCEPTION: Any Any two two of of the the following three types of of damage damage are are acceptable: acceptable:Figure 6 1Figure 6-1Note: This rule applies to windscreens repaired with clear resins. After repair, there must be no visible damage beyond theNOTE: This limits rule given applies above. to windscreens repaired with clear resins. Afterrepair, there must be no visible damage beyond the limits givenabove.6.3 Test the light transmittance level of the windscreen,side and rear windows3 Test the light transmittance level of the windscreen, sided rear windowsNote: (i) This section should be read in conjunction with the light meter manufacturers’ instructions.NOTE: (i) This section should be read in conjunction with the lightmeter (ii) The manufacturers' light meter may instructions. have up to a 5% measuring inaccuracy. A vehicle may be accepted if the readings are up to 5%lower than the minimum light transmittance.(ii) The light meter may have up to a 5% measuring inaccuracy.Reasons for rejectionA vehicle may be accepted if the readings are up to 5% lower thana) the Any minimum windscreen light glazing transmittance. has any coating which reduces its light transmittance other than in the area described intable below.easons for rejection30 a) <strong>Light</strong> <strong>Vehicle</strong> Any windscreen <strong>Inspection</strong> <strong>Manual</strong> glazing has any coating which reduces its lightVersion 11, December 2013transmittance other than in the area described in table below;

) Tint films are not free of bubbles, scratches or other defects that significantly affect the driver’s vision.c) The visible light transmittance of any glazing (including any applied film) is less than that detailed in the table below.Tasmanian <strong>Inspection</strong> <strong>Manual</strong> for <strong>Light</strong> <strong>Vehicle</strong>sd) Tinted film has more reflective reflection (metallic or mirror like) than the untreated glass.GlazingMinimum <strong>Light</strong>TransmittanceWindscreen 75% 70%All other windows 35% 30%<strong>Vehicle</strong>s NOT TO BEREJECTED until meterreadings are LESS thanNo limit for windows to the rear of the driver ifthe vehicle is a bus, stretch limousine,ambulance or hearse.No limit for windows with glazing or coatingfitted before 1 October 1996 behind the rear ofthe driver’s seat of the vehicleNo limit for windows with glazing or coatingadjacent to the rear of an area of a motorvehicle designed and built to carry goods.No limit for a tinted or opaque band at the top ofthe windscreen, provided it is above the arcswept by the windscreen wipers, or the upper10% of the windscreen, whichever is the lesser.Note: For further information on Windscreens, refer toAppendix G’ Windscreen Damage and Repair’Note:For further information on Windscreens, refer to Appendix G’ Windscreen Damage and Repair’6.4 Visually inspect body panels, chassis and sub frame for6.4 dangerous Visually inspect protrusions body panels, chassis and and rust sub frame forReasons dangerous for rejection protrusions and rusta) exterior body work and fittings have sharp edges due to rusted panels or body damage, or protrusions of anyReasons after for market rejection object or fittings, not technically essential to the operation of the vehicle, which protrudes from anypart of the a) vehicle exterior that could body cause work injury and fittings to a person have coming sharp into edges contact due with to rusted the vehicle.b) any structural member panels or such body as a damage, sub frame, or floor protrusions panel, door of sill, any seat after or seat market belt anchorage, object is cracked or hasadvanced rust. or fittings, not technically essential to the operation of the vehicle,c) Unrepaired damagewhichorprotrudesmodificationsfromaffectingany parttheofstructuralthe vehicleintegritythatofcouldthe vehicle.cause injuryto a person coming into contact with the vehicle;d) Any evidence that body has been cut and joined.b) any structural member such as a sub frame, floor panel, door sill,e) where ADR 29 applies, the doors of a vehicle have advanced rust.seat or seat belt anchorage, is cracked or has advanced rust;f) chassis frame members or supporting members are cracked, loose, sagging or broken.c) Unrepaired damage or modifications affecting the structuralg) frame members in load areas are missing, damaged or unsecured.integrity of the vehicle;h) tilting cabin or tray latches do not hold the cabin or tray securely in the operating position.d) Any evidence that body has been cut and joined;i) a bull bar is not approved by the manufacture to comply with the requirements of ADR 69 and supplementaryrestraint e) system where (SRS) air ADR bag 29 compatible applies, where the doors required. of a vehicle have advanced rust;Note: Refer to Appendixf) chassisO modificationsframe membersbrochure onorbullsupportingbarsmembers are cracked,loose, sagging or broken;j) Any repairs carried out do not retain the original strength of the component/section.g) frame members in load areas are missing, damaged or unsecured;k) any object or fitting, not technically essential to such vehicle, which protrudes from any part of the vehicle so thatit is likely to increase the risk of bodily injury to any person.l) Any component that adversely affects the safety of the vehicle, and in particular, obscures the drivers view.Version m) Tow 4 – bar 1 May mounted 2009 bicycle carrying racks or similar devices are not removed when not in Page use, unless 32 specificallydesigned to fold away.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 31

first line delete “August 2011” and insert “June 2012” Administration of the manual Page 11 – Version control At the end of the first line delete “August 2011” and insert “June 2012” n) A bicycle and the carrier assembly (or similar, when fitted) obscures any compulsory lighting or the number plate.transmittance level of the windscreen side and rear windows .3 c) insert the following: o) Permanently mounted fishing rod holders, driving lights and fog lights protrude above or forward of the top railor leading edge of the bumper or bull bar.SECTION 6 6.3 test the light transmittance level of the windscreen side and rear windows Page 31 – after 6.3 c) insert the following: p) Temporarily attached rod holders are not removed or adjusted so as to meet the above requirement when notin use.s more reflective reflection (metallic or mirror like) than the untreated glass. 6.5 Dimensionsd) Tinted film has more reflective reflection (metallic or mirror like) than the untreated glass. ect body Reason panels, for rejection chassis and sub frame for dangerous protrusions and rust 4 and its contents a) The width insert of the vehicle a new exceeds 6.5 2.5 metres below and amend all section numbers thereafter6.4 Visually inspect body panels, chassis and sub frame for dangerous protrusions and rust b) The height of the vehicle exceeds 4.3 metresPage 32-‐ after 6.4 and its contents insert a new 6.5 below and amend all section numbers therfor c) section The length 6 of the vehicle exceeds 12.5 metres6.5 Rear overhang g tion 6.6 Rear overhangReason for rejectionng (RO) of the vehicle exceeds the lesser of the following two measurements: eelbase or -‐3.7 metres. ng of a trailer exceeds the lesser of the following measurements: he load-‐carrying area forward of the rear overhang line or 3.7 metres. Reason for rejection a) The rear overhang (RO) of the vehicle exceeds the lesser of the following two measurements: a) The rear overhang (RO) of the vehicle exceeds the lesser of the following two measurements:-‐ 60% of the wheelbase or -‐3.7 metres. - 60% of the wheelbase or -3.7 metres.b) The rear overhang of a trailer exceeds the lesser of the following measurements: b) The rear overhang of a trailer exceeds the lesser of the following measurements:-‐ length of the load-‐carrying area forward of the rear overhang line or 3.7 metres. - The length of the load-carrying area forward of the rear overhang line or 3.7 metres.ROH Wheelbase ROH 6.7SECTIONInspect 8 the wheel arches/mudguards and mudflaps,with the wheels in the “straight ahead” position8.7 Visually inspect the headlights Page 40 -‐ after 8.7 d insert the following e) The headlight lens shows deterioration reducing the effectiveness of the headlight from initReasons for rejectiona) Mudguards are not fitted to all wheels of passenger and goods type vehicles.b) The mudguard and/or bodywork covering any wheel is not at least as wide as the tyre over the arc betweenmanufacture.points Tasmanian A and <strong>Inspection</strong> B in the diagram. <strong>Manual</strong> for <strong>Light</strong> <strong>Vehicle</strong>sPoint C (being on the rear edge of the mudguard/mudflap/ bodywork and in line with the centreline of the tyre -Point C (being on see the diagram) rear edge is more of the than mudguard/mudflap/ 150m in vertical bodywork distance and above the centre of the wheel. NOTE: Points along the rearSECTION 10 in line with the centreline edge which of are the inboard tyre - see of diagram) Point C is should more also than meet 150m this in requirement. A mudflap which is too flexible to maintain itsposition during normal driving conditions should be disregarded for this check.ct the headlights .7 d insert the following lens shows deterioration reducing the effectiveness of the headlight from initial 10.10 Visually inspect shut of devices, converters (vaporiser regulators), fuel selectors and air/mixers. Page 49-‐ After 10.10 i) insert the following i) Any gas leaks. pect shut of devices, converters (vaporiser regulators), fuel selectors and air/gas .10 i) insert the following 32 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>vertical distance above the centre of the wheel. NOTE: Points along the 1 Version 11, December 2013rear edge which are inboard of Point C should also meet thisrequirement. A mudflap which is too flexible to maintain its position

c) For a passenger car the lower edge of the mudflap is more than 230 mm above ground level when parked onlevel ground.d) For a vehicle with off road capabilities the lower edge of the mudflap in more than 300 mm above ground levelwhen parked on level ground.Note:For further information on Mudguard requirements, refer to Appendix H’ Mudgaurd and Mudflap Requirements’.6.8 Visually inspect rear vision mirrorsOBJECTIVE: To ensure that the mirrors and associated components are in such a condition that the driver has a clear fieldof vision by reflection of the road behind the vehicle and any following or overtaking vehicles at all times under the normalrange of climatic conditions.Reasons for rejectiona) rear vision mirrors are cracked, loss of reflectivity, missing, or do not provide a clear view of the road to the rearof the vehicle.b) where there is no effective rear vision provided by the internal rear vision mirror, the vehicle does not have anexternal rear vision mirror fitted to each side.c) any light commercial vehicle (except a station wagon) is not fitted with an external rear vision mirror on eachside of the vehicle.d) mirrors are not securely mounted.e) mirrors are obscured.f) The right side rear vision mirror fitted to a vehicle over 3.5 tonnes Gross <strong>Vehicle</strong> Mass (GVM) is not fitted with aflat reflecting surface.6.9 Visually inspect and check the operation of thewindscreen wipers and windscreen washersReasons for rejectiona) The windscreen wipers are not operational at all speeds and do not return to their normal parked position.b) windscreen wiper blades are missing, cracked, curled, frayed or torn.c) windscreen washers do not work or are not correctly aimed onto the windscreen.g) the windscreen washer is not able to be operated from a normal driving position.6.10 Check the operation of the hornReasons for rejectiona) A warning device (horn) is not fitted and operational and the tone is not of a single pitch.b) A warning device (horn) is not clearly audible and the actuating mechanism is not located within the reach of thedriver in the normal seated position.6.11 Visually inspect the front and rear number platesReasons for rejectiona) number plate is obscured, for example by a towing attachment goose neck, or tow ball.b) number plate covers are tinted, reflective, rounded, or bubble like.c) the number plate is damaged or faded to the extent that the registration number is not legible from a distance oftwenty metres.d) number plate has a substance applied to the reflective surface that would prevent the production of a clearphotograph.e) the registration (number) plate is not issued or approved by the State or Territory Road <strong>Transport</strong> Authority.f) The number plate is mounted more than 1300mm from the ground.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 33

g) The number plate does not face the front or rear in an upright position parallel to the vehicles axles.h) Characters in the number plate are not clearly visible from a distance of 20 metres at any point within an arc of45 degrees from the surface of the number plate above or to either side of the vehicle.6.12 Where ADR 25 applies, check the operation of theanti-theft/steering lockReasons for rejectiona) the ignition key can be removed in any position except the “anti-theft” (lock) position.b) when engaged, the anti-theft lock does not prevent at least one of the following actions.• steering the vehicle.• engaging the forward drive gears.• release of the brakes.6.13 Where ADR 42 applies, check the operation of thewindscreen demisterReasons for rejectiona) A motor vehicle that is fitted with a windscreen other than a motorcycle that is not fitted with a device capableof removing condensed moisture from the inside of the windscreen.6.14 SpeedometerReason for rejectiona) speedometer is not operational.b) speedometer indicator values are not legible.c) The speedometer is not calibrated in km/h and the vehicle was manufactured on or after 1 July 1988.34 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Section 7:Seats and SeatbeltsAustralian Design Rules relevant to this section:ADR 3 Seat anchoragesADR 4 SeatbeltsADR 5 Anchorages for seatbelts and child restraintsADR 22 Head restraintsADR 34 Child restraint anchorages and child restraint anchor fittingsADR 69 Full frontal impact occupant protectionOBJECTIVE: To ensure that all seating and restraints fitted to the vehicle provide a comfortable and secure position for thedriver to control the vehicle and control the deceleration of all vehicle occupants7.1 Check seatsReasons for rejectiona) Seat frames or attaching points are loose, cracked, broken or have fasteners missing.b) Any seat has an exposed sharp edge or other parts that protrude due to damage.c) Seat cushions and backrests are not fitted.d) A seat slide or other seat control used for adjustment of a seating position is not operational and does not holdany selected position allowed for in the mechanism’s design.e) Any reduction, increase, or modification in seating is not certified by an approved modification plate.f) The fittmant of non original equipment manufacturer seats not certified by an approved modification plate.g) Any passenger car, forward control vehicle passenger vehicle or off road passenger vehicle or light omnibus (up to12 seats) that was built after 1 July 1988 is not fitted with head restraints to each front outboard seating position.h) Any light goods vehicle (GVM not exceeding 3.5 t) manufactured after 1 July 1996 is not fitted with headrestraints to the front outboard seating positions.i) Unapproved seat covers fitted to seats that have Supplementary Restraint System (SRS) fitted7.2 Check the operation of seats, seat belts, buckles andother restraints, and inspect webbing and metal stalksReasons for rejectiona) Seat belt assemblies are not securely attached to the respective anchorage point and show signs of distortion,cracks, fractures or other damage likely to cause failure.b) Any retractor, locking mechanism, buckle, tongue or adjustment device is inoperative.c) any metal stalk is missing or has broken wires.d) in other than ADR 34 vehicles, where fitted, child restraint attachment points are loose or cracked.e) where ADR 34 applies, child restraint attachment points are loose, cracked or missing.Non retractable seat belts do not have sufficient adjustment to allow effective use of the belts and do not maintain theadjusted positions.g)Where ADR 69 applies, the seatbelt warning light does not operate for a minimum of 10 secondswhen the ignition is switched to the on or start position.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 35

f) Seatbelt webbing that is.1. Damaged.2. Frayed.3. Stretched.4. Tied in a knot.5. Twisted.6. Split.7. Torn.8. Cut.9. Altered or modified.10. Severely deteriorated.11. Burnt.12. Not correctly and firmly secured to each end fitting.13. Webbing/stitching becoming detached at any point.NOTE:Note:Discolouring alone is not a reason for rejection.For further information on Seatbelts, refer to Appendix I’ Australian Design Rule – Seatbelt Requirements.’36 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Section 8:<strong>Light</strong>ingAustralian Design Rules relevant to this section:ADR 1 Reversing lamps.ADR 6 Direction indicator lampsADR 13 Installation of lighting on other than L group vehiclesADR 19 Installation of lighting on L group vehiclesADR 45 <strong>Light</strong>ing not covered by ECE regulationsADR 46 Head lampsADR 47 Reflex reflectorsADR 48 Rear registration plate illuminating devicesADR 49 Front and rear position (side) lamps, stop lamps and end-outline marker LampsADR 51 Filament globesADR 60 Centre high mounted stop lampsOBJECTIVE: To ensure that all lights, reflectors and other electrical lighting components as required by prescribed standardsare operational.8.1 Visually inspect the compulsory reflectors fitted to therear of the vehicleReason for rejectiona) Red reflector(s) are damaged, discoloured or missing (note: reflectors may be incorporated in the lampassembly).8.2 Visually inspect and check the operation of all lightsfitted to the vehicleReasons for rejectiona) any of the following lights do not work or has incorrect colour.(i) headlight (high/low beam) (white)front park or side lights (white)tail lights (red)brake light(s) (red)turn signal indicator lights (yellow)clearance lights (trucks and cycle type vehicles only) (front: yellow/white, side: yellow, rear: yellow/red)number plate light (white).b) any rear light other than a reversing light is in a condition or damaged to the extent that white light shows to therear of the vehicle.c) any yellow clearance light or front turn signal is damaged so that it shows white light.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 37

d) the number plate light is not directing light onto the surface of the rear number plate.e) Any optional lights or reflectors interfere with any compulsory lights or reflectors.f) Additional lighting (fitted as accessories) is fitted in such a way that their operation will impair the operation ofstatutory lighting, and contravene prescribed standards.g) lights as follows are not fitted to pre 3rd Edition ADR vehicles (passenger and light goods vehicles and lightomnibuses) (dimensions at centre of lights).At front of vehicle:(1) 2 White Main beam (high beam) headlights, min 500mm off ground, with min separation of 600mm.(2) 2 White Dipped beam headlights, min 500mm and max 1400mm off ground, min 600mm separation.(3) 2 White Park lights, min 500mm off ground, max 510mm inboard of vehicle side, wired to remain “on” withheadlights if vehicle built after 1969. Note: vehicles manufactured prior to June 1953 are not required to be fittedwith park lights.(4) 2 Yellow turn signal indicators (7/73 onwards, pre 7/73 may be white), min 350mm and max 1500mm fromthe ground (if 1500mm not practicable 2100mm), min 400mm separation if vehicle less than 1300mm wide or600mm if vehicle over 1300mm wide, max 500mm inboard of vehicle side; Note: vehicles manufactured prior toAugust 1966 are not required to be fitted with directional indicators.(5) 2 Yellow or White clearance lights (where vehicle is over 2.2m wide), min 750mm above headlights, max 400mminboard of side of vehicle; Note front clearance lights must not be fitted to a vehicle that is less than 1.8 metresin width.(6) 2 Hazard warning lights (10/91 onwards), incorporated with turn signal indicators.(7) Optional White or yellow fog lights, mounted no higher than the headlights wired through park lights on aseparate switch, may also operate when main and/or dipped beam headlights are illuminated.(8) Additional main beam headlights (driving lights) are not fitted in pairs to a maximum of 4 lights.(9) Additional Main beam headlights (driving lights) are not wired so that they extinguish when switched to dippedbeam, park light or off positions.(10) Additional Main beam headlights (driving lights) are not forward facing.(11) Additional Main beam headlights (driving lights) are mounted in such a way that they are a dangerous protrusionor interfere with the drivers vision.(12) Additional Main beam headlights (driving lights) are mounted in such a way that when on they reflect light backto the driving position.At Side of vehicle:1) 2 Yellow to front, red to rear side marker lamps (where vehicle is more than 2.2m wide and/or 7.5m long), min600mm and max 1500mm off ground, max 300 mm from rear of vehicle.At Rear of vehicle:1) 2 (1 prior to 1959) Red tail lights, max 1500mm off ground, min 600mm apart, max 400mm inboard of side ofvehicle (single light located in centre or right side of vehicle).2) 2 Red reflectors, max 1500mm off ground, max 400mm (250mm if vehicle more than 2.2m wide) inboard of sideof vehicle.3) 2 (8/72 onwards) white or yellow reverse lights, max 1200mm off ground.4) White registration plate lamp/s, to illuminate registration plate.5) 2 (1 prior to 1959) Red stop lights, min 300mm and max 1500mm off ground (single light to be in centre or onright side of vehicle).6) 2 Yellow (red permitted prior to 7/73) turn signal indicators, min 350mm and max 1500mm off ground, min600mm separation. Note: vehicles manufactured prior to August 1966 are not required to be fitted withdirectional indicators.7) 2 Hazard warning lights (10/91 onwards), incorporated with turn signal indicators.38 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

8.3 Visually inspect and check condition of all lights fittedto the vehicleReasons for rejection:a) Any light is not clearly visible under all normal conditions and of a consistent intensity, or are affected by dirtylenses or poor electrical contact.b) Reflector surfaces are not free of tarnish or other damage, which could reduce the intensity of high or low beam.c) Headlights are not correctly focused.d) Lenses and light reflectors are not securely mounted, are faded or discolored and are not free from cracks, holes,or other damage which would allow the entry of moisture or dirt to impair the efficiency of the light or reflector.8.4 Visually inspect and check light switch operationReasons for rejection:a) The headlight high beam tell tale indicator light is not operating.b) Additional headlights (driving lights) do not operate in conjunction with the high beam circuit, and are not fittedwith an independent on/off switch.c) The high/low headlight switch and turn signal switch is not readily operable by the driver from the driving positionand, if fitted as original equipment by the manufacturer, is not self-cancelling.d) The turn signal operation is not indicated by means of a visible and/or audible telltale.e) The reverse light (if applicable) operates other than when reverse gear is selected.f) Any fog lights fitted can not be switched independently of the main or dipped beam headlamps.g) Fog light switch (after September 1991) does not have a tell tale indicator to indicate that the switch is on.8.5 Visually inspect front and rear lights for the presenceof tinted coversReasons for rejectiona) any light has a tinted cover over it, or any tinting applied to it.b) there is any opaque cover over a headlight which cannot be readily removed without the use of tools.8.6 Using a headlight tester, check the aim of theheadlightsReasons for rejectiona) the aim of the headlight is adjusted such that, when on high beam and measured at an effective distance of 8m,the projected centre of the beam is to the right of the headlight centre and/or is above the headlight centre.b) when measured at an effective distance of 8m, any part of the top edge of the high intensity portion of the lowbeam pattern is above and/or to the right of the centreline of the headlight.NOTES:In the region above and to the right of the centreline of the headlight the luminous intensity must not exceed 437cd.The portion of the beam to the left of the centreline of the light may extend above the height of the centreline of the headlight.The “centreline of the headlight” passes through the centre of the globe filament, or equivalent.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 39

8.7 Visually inspect the headlightsReasons for rejectiona) headlight reflector is tarnished or peeling to the extent that headlight performance is impaired.b) headlight lens is incomplete.c) headlight assembly is not secured.d) headlight is water damaged or has incorrect beam pattern.e) the headlight lens shows deterioration reducing the effectiveness of the headlight from initial manufacture.Note:For further information on lighting requirements, refer to Appendix J’ <strong>Light</strong>ing Standards’ and Appendix K ‘Headlamptesting Screens’.40 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013

Section 9:Engine Compartment & DrivelineADRs applicable to this section:ADR 42 General safety requirementsADR 79 Emission Control for light vehiclesADR 80 Emission control for Heavy <strong>Vehicle</strong>sADR 83 External NoiseOBJECTIVE: To ensure that engine and driveline components are compliant with the regulations and operate in a safe manner.9.1 Visually inspect the engine, transmission and drivelinefor oil/fluid leaks.Reasons for rejectiona) oil is leaking from the engine, gearbox, differential, or from any joint or seal onto any of the following.1. brake friction surfaces.2. the exhaust system.3. oil or fluid dripping onto the road surface, at a rate of more than one drop every 30 seconds.b) Evidence of oil or fluid leaking from any brake or power steering component.9.2 Visually inspect engine, transmission and drivelinecomponentsReason for rejection:a) any engine or transmission mounting is cracked or not secured.b) rubber components are severely perished, broken or deteriorated.c) fasteners on couplings in the driveline are cracked, loose or missing.d) any transmission drive shaft is bent, damaged, loose or noticeably misaligned.e) any universal or constant velocity joint has excessive wear, is misaligned, seized, is not securely attached, or has adamaged or missing boot.f) where an automatic transmission is fitted, the engine can be started in any gear position other than neutral orpark (ensure that brakes are applied during this test).g) any modifications to engine, transmission and driveline components that does not have modification approvalNOTE: For further information on modifications, refer to Appendix O modification brochure9.3 Visually inspect the electrical systemReasons for rejection:a) A battery (s) is not secured in a cradle or carrier using hold down clamps, is cracked, leaking or has missing caps.b) A battery mounted in the interior of a bus is mounted to allow acid or fumes to come into contact withpassengers or goods.<strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong>Version 11, December 2013 41

c) Electrical wiring is not securely mounted and insulated, is exposed to excessive heat.d) Wiring not supported at 600 mm or less intervals.e) Chafing or located in such a way that would cause danger to the operation of the vehicle.f) Electrical wiring hinders driver or passenger movement.g) Any electrical wiring or connector that is corroded damaged, not insulated or securely fastened so that it couldbe damaged.h) Electrical wiring is unprotected from abrasion.i) Wiring is exposed to excessive heat.j) Wiring is in contact, or can contact moving parts.9.4 Visually inspect the exhaust systemReasons for rejectiona) any component of the exhaust system that is cracked, or not securely mounted.b) the exhaust system is not fitted with an effective silencing device through which all of the vehicles exhaust pass.c) exhaust pipe outlet is not rearward of all side passenger doors and opening windows and more than 40 mmbeyond any floor joint that is not continuously sealed or welded.d) Exhaust pipe outlet discharges to the left-hand side of the vehicle.e) there is any leak in the exhaust system, excluding manufacturers’ drain holes in the mufflers.f) exhaust outlet does not extend to the outline of the vehicle body..g) the exhaust system fouls any part of the steering, suspension, brake or fuel system.h) the exhaust does not have a ground clearance equal to or more than 100 mm.i) emission control equipment (where required) missing or not operative.j) the engine lets out sparks, flames, excessive gases, oil or fuel residue.k) for a vehicle manufactured after 1930 and propelled by an internal combustion engine, the vehicle emits visibleemissions for a continuous period of more than 10 seconds.NOTE:A vehicle should not be rejected for emissions that are visible only because of heat or the condensation of water vapour.9.5 Visually inspect the fuel systemReason for rejectiona) there is any leakage from the fuel system.b) any part of the fuel system is insecure or damaged so that there is a risk of a fuel leak.c) the fuel cap is missing, insecure, or of the incorrect type.d) the air cleaner is not fitted.e) Engine speed does not return to normal idle position upon release of the accelerator pedal or throttle control.f) Nitrous oxide injection equipment is fitted irrespective of its operational ability.g) Multiple and/or replacement carburetors fitted to any motor vehicle do not continue to comply with theemission requirements of the Australian Design Rules applicable at the time of the vehicle’s manufacture.42 <strong>Light</strong> <strong>Vehicle</strong> <strong>Inspection</strong> <strong>Manual</strong> Version 11, December 2013