Bosch Automotive A product history

Bosch Automotive A product history - Bosch worldwide

Bosch Automotive A product history - Bosch worldwide

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Bosch</strong> <strong>Automotive</strong><br />

A <strong>product</strong> <strong>history</strong><br />

Journal of <strong>Bosch</strong> History<br />

Supplement 2

2 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

Foreword<br />

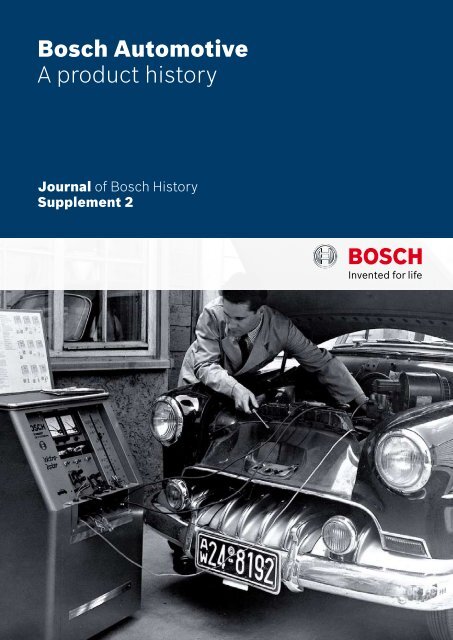

Title illustration:<br />

<strong>Bosch</strong> and automotive<br />

technology are inseparably<br />

linked. The title<br />

illustration from 1955<br />

shows <strong>Bosch</strong> testing<br />

equipment at work,<br />

checking the ignition<br />

system of an Opel<br />

Olympia Rekord.<br />

The magneto ignition device for motorized carriages that was first delivered<br />

to a customer in 1898 marks our first major milestone as an automotive<br />

supplier. There were numerous other important milestones on our way to<br />

becoming a global automotive supplier with a wide range of automotive<br />

systems, components, and services. Examples include the diesel injection<br />

pump, the Jetronic electronic gasoline-injection system, the ABS antilock<br />

braking system, the ESP® electronic stability program, and common rail.<br />

Today, our <strong>product</strong>s help a lot to cut fuel consumption and emissions, and<br />

to make driving safer and more comfortable. <strong>Bosch</strong> technology can be found<br />

in virtually every vehicle on the road, whether helping to stabilize vehicle<br />

dynamics in critical situations, automatically maintaining a safe distance<br />

from the vehicle in front, finding the most economical way to reach a destination,<br />

or improving visibility at night.<br />

With his finely honed entrepreneurial instinct, Robert <strong>Bosch</strong> was quick to<br />

latch on to good ideas. He then used his technical flair and commercial<br />

expertise to turn them into high-quality <strong>product</strong>s that represented excellent<br />

value for money. The principles that he formulated and lived by still shape<br />

our company, our values, and our actions today. They help us turn challenges<br />

into opportunities. Examples in automotive engineering include recognizing<br />

the potential for growth in Asia, realizing the potential of the electric car,<br />

supporting the associated emergence of new concepts of mobility, as well<br />

as participating in the trend toward smaller vehicles.<br />

Although <strong>Bosch</strong> is now a technology and services company that is active in<br />

many other areas, our automotive business sector has always been at the<br />

heart of what we do. No other business sector can look back on such a long<br />

or multifaceted <strong>history</strong>. The purpose of this brochure is to relate this <strong>history</strong>,<br />

and I hope it makes for interesting reading.<br />

Best regards<br />

Bernd Bohr<br />

Member of the Board of Management<br />

and Chairman of the <strong>Bosch</strong> <strong>Automotive</strong> Group

<strong>Bosch</strong> <strong>Automotive</strong> | 3<br />

Contents<br />

4 We have ignition! <strong>Bosch</strong> becomes<br />

an automotive supplier<br />

6 Spark emitter and trademark<br />

<strong>Bosch</strong> magneto ignition<br />

14 “Safe night-time driving at last!”<br />

<strong>Bosch</strong> automotive lighting systems<br />

20 Well equipped, whatever the<br />

weather<br />

Equipment for day-to-day driving<br />

28 <strong>Bosch</strong> engine management – not<br />

just for smooth operation<br />

30 From heavy-oil pumps to piezo<br />

injectors<br />

<strong>Bosch</strong> diesel injection systems<br />

38 Not just a matter of horsepower<br />

<strong>Bosch</strong> gasoline injection systems<br />

46 A future for electric vehicles<br />

Alternative drive systems from <strong>Bosch</strong><br />

50 Drives like a dream – safety,<br />

guidance, and comfort<br />

52 Past every obstacle<br />

Braking and chassis systems<br />

made by <strong>Bosch</strong><br />

58 The sensitive car<br />

Driver assistance systems<br />

made by <strong>Bosch</strong><br />

64 Entertainment combined with<br />

traffic and road information<br />

Car multimedia<br />

70 “Safe, clean, economical”<br />

as a development goal<br />

72 Safe, clean, economical<br />

The <strong>Bosch</strong> 3S program<br />

76 What’s what?<br />

Glossary of automotive<br />

components<br />

Left:<br />

A car with no <strong>Bosch</strong><br />

parts? As this advertising<br />

poster from 1998 indicates,<br />

only toy cars fulfill<br />

this criterion.<br />

Right:<br />

A car with <strong>Bosch</strong> parts.<br />

With X-ray vision, you<br />

would see the multitude<br />

of <strong>Bosch</strong> electrical,<br />

electronic, and mechanical<br />

components in a car.

4 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

We have ignition!<br />

<strong>Bosch</strong> becomes an<br />

automotive supplier<br />

In the company’s early days, the<br />

directors still performed tests<br />

themselves. From left to right:<br />

Gustav Klein, head of sales;<br />

Gottlob Honold, head of development;<br />

Ernst Ulmer, head of commercial affairs;<br />

and Arnold Zähringer, technical director

<strong>Bosch</strong> <strong>Automotive</strong> | 5

6 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

Spark emitter and trademark<br />

<strong>Bosch</strong> magneto ignition<br />

The origins of <strong>Bosch</strong> as a supplier of automotive equipment go back to 1887.<br />

This was the year in which, on behalf of a customer, the 25-year-old electrician<br />

and precision mechanic Robert <strong>Bosch</strong> built a <strong>product</strong> that was later to play an<br />

important role in the automobile – a magneto ignition device for a stationary<br />

engine. In 1897, <strong>Bosch</strong> installed one of these devices in a motorized three-wheeler<br />

to see whether it was suitable for everyday use in motor vehicles. This unwieldy<br />

apparatus became a key <strong>product</strong> of the company. It turned <strong>Bosch</strong> into an automotive<br />

supplier both inside and outside Germany. Ignition systems have undergone<br />

further development since then, and are now integrated into complex engine<br />

management systems. But one thing has remained the same. Even today, an electric<br />

spark ignites the air-fuel mixture and keeps gasoline engines running.<br />

The high-voltage<br />

magneto ignition<br />

system with spark<br />

plug was suitable<br />

for universal use and<br />

made <strong>Bosch</strong> highly<br />

successful virtually<br />

overnight.<br />

Magneto ignition is based on a double-T<br />

armature around which a wire coil has been<br />

wound. It moves in a magnetic field, thus<br />

generating a current. Robert <strong>Bosch</strong> was<br />

by no means the inventor of this principle.<br />

As early as 1866, Werner von Siemens used<br />

it in his dynamo-electric machine. And in<br />

1876, building on this basis, Nicolaus<br />

August Otto developed the break-spark<br />

ignition device. He needed this to generate<br />

ignition sparks in his four-stroke engines.<br />

Nine years later, at the request of a customer,<br />

Robert <strong>Bosch</strong> first built a magneto<br />

ignition device for a stationary engine.<br />

When testing the device, however, he found<br />

that it was not really suitable for everyday

<strong>Bosch</strong> <strong>Automotive</strong> | 7<br />

use. So he set about making improvements,<br />

for example by using more robust U-shaped<br />

magnets (also called horseshoe magnets).<br />

Further orders followed, and some five<br />

years later magneto ignition devices already<br />

accounted for roughly half the young company’s<br />

sales.<br />

Magneto ignition in the car<br />

In automobile manufacturing, which in<br />

those days was still in its infancy, ignition<br />

was proving to be the “trickiest problem”<br />

facing automakers – as automotive pioneer<br />

Carl Benz observed. The naked flame in<br />

Gottlieb Daimler’s glow-tube ignition system<br />

constituted a constant fire hazard,<br />

while safe battery-powered ignition systems<br />

restricted the range of cars to a few dozen<br />

kilometers, since the battery soon needed<br />

recharging and the system did not have a<br />

generator to accomplish this task while<br />

driving.<br />

In 1897, Robert <strong>Bosch</strong> installed one of<br />

his magneto ignition devices in a vehicle<br />

engine. This was something completely<br />

new. His customer was the English engineer<br />

Frederick Simms, a member of Daimler’s<br />

supervisory board. He asked <strong>Bosch</strong> to<br />

install a magneto ignition device in a De<br />

Dion-Bouton three-wheeler. Robert <strong>Bosch</strong><br />

found that, in the design that had existed<br />

The flaring spark plug,<br />

designed by Lucian<br />

Bernhard in 1912, was<br />

the most enduring motif<br />

in <strong>Bosch</strong> advertising. It<br />

appeared on spark-plug<br />

packaging until the<br />

1970s.

8 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

The Daimler Phoenix<br />

truck was the first motor<br />

vehicle to be equipped<br />

with a <strong>Bosch</strong> magneto<br />

ignition device as standard<br />

equipment.<br />

hitherto, the magneto ignition device was<br />

unsuitable for such an engine. The device<br />

itself was capable of delivering a maximum<br />

of 200 sparks per minute, yet the small<br />

De Dion-Bouton engine ran at a maximum<br />

speed of 1,800 rpm and thus required<br />

900 ignition sparks per minute.<br />

The solution for high-speed engines<br />

Arnold Zähringer, <strong>Bosch</strong>’s factory manager,<br />

came up with the solution. Instead of moving<br />

the ponderous armature itself through<br />

the magnetic field, he left this job to a lightweight<br />

metal sleeve which he laid around<br />

the armature. Zähringer’s invention was<br />

patented for <strong>Bosch</strong>. The innovative ignition<br />

device had in theory solved a major problem<br />

for the young automotive industry –<br />

ignition in high-speed internal-combustion<br />

engines in vehicles. However, the complicated<br />

break-spark rodding needed to create<br />

the ignition spark in the combustion chamber<br />

remained a weakness in its design.<br />

This rodding had to be redesigned for every<br />

engine. It also required considerable maintenance<br />

and was prone to breakdown.<br />

High voltage and spark plugs<br />

In the summer of 1901, therefore, Robert<br />

<strong>Bosch</strong> gave his colleague Gottlob Honold<br />

the brief of designing a magneto ignition<br />

system without break-spark rodding. After<br />

just a few months, Honold presented his<br />

high-voltage magneto ignition system,<br />

based on what was known as electric arc<br />

ignition. By means of two coils on the<br />

armature, it generated a high-voltage current.<br />

This was conducted to a spark plug<br />

via a simple cable connection. The highvoltage<br />

current jumped the gap between<br />

its electrodes in the form of a spark.

<strong>Bosch</strong> <strong>Automotive</strong> | 9<br />

A spark plug design with fixed electrodes<br />

had been around since about 1860. Carl<br />

Benz, for example, already used spark<br />

plugs for gasoline engines, but with little<br />

success. The materials used for both the<br />

insulation and the electrodes proved unsuitable.<br />

Honold developed a better ceramic<br />

for the insulating body and a heat-resisting<br />

alloy for the electrodes. This brought magneto<br />

ignition up to a technological standard<br />

that guaranteed it success.<br />

The spark plug itself was in fact only a<br />

by-<strong>product</strong> that <strong>Bosch</strong> had to manufacture<br />

in order to be able to offer a complete<br />

system. Events took an interesting turn,<br />

though. While magneto ignition has long<br />

since disappeared, <strong>Bosch</strong> still manufactures<br />

spark plugs – more than 300 million each<br />

year.<br />

Magneto ignition became established in<br />

automobiles even before the first world<br />

war. Thanks to modern manufacturing<br />

methods, such as assembly-line <strong>product</strong>ion<br />

from 1925 on, millions of these systems<br />

were manufactured to a high quality standard.<br />

Nonetheless, the automotive industry<br />

began to call for less expensive ignition<br />

systems. After all, around 1930, a magneto<br />

ignition for a mid-size automobile cost<br />

roughly 200 reichsmarks – twice the salary<br />

of a <strong>Bosch</strong> worker, and a tenth of the cost<br />

of a small car.<br />

Spectacular application: the very first Zeppelin<br />

LZ1 airship in 1900 was equipped with a magneto<br />

ignition device from <strong>Bosch</strong>. It was the most<br />

reliable ignition device available, and did not pose<br />

a fire risk, unlike other systems.

10 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

Bottom:<br />

Camille Jenatzy driving<br />

a Mercedes in the 1903<br />

Gordon Bennett Race<br />

in Ireland. Jenatzy won<br />

the race using a <strong>Bosch</strong><br />

ignition system, establishing<br />

its reputation for<br />

especially high quality.<br />

Battery ignition offers a less<br />

expensive solution<br />

This cost issue was why <strong>Bosch</strong> started<br />

refining battery ignition, which was a less<br />

expensive solution, as from 1920. Although<br />

ignition systems that worked with a current<br />

from batteries existed prior to 1900, the<br />

batteries of the time had little storage<br />

capacity and could not be recharged while<br />

the car was on the move. This ignition<br />

system was thus impracticable for everyday<br />

use. Magneto ignition systems, by contrast,<br />

worked independently of any source of<br />

current. They generated their voltage with<br />

the help of kinetic energy from the engine<br />

with which they were connected.<br />

As from 1910, however, it became technically<br />

feasible to produce a battery ignition<br />

system that was suitable for everyday<br />

use. The electricity that was used up by<br />

ignition could be replaced by the generator<br />

(which <strong>Bosch</strong> began manufacturing<br />

in 1913) while the car was on the move.<br />

This allowed <strong>Bosch</strong> to meet customers’<br />

demands for cost-effective solutions. At<br />

first, the company mainly supplied battery<br />

ignition systems – comprising ignition coil,<br />

ignition distributor, spark plugs, and<br />

cables – for small and standard-sized cars.<br />

The ignition coil generated high-voltage<br />

current, and the distributor transferred this<br />

Milestones<br />

1887 1897 1902 1908 1910 1921<br />

Low-voltage<br />

magneto ignition for<br />

stationary engines<br />

Low-voltage<br />

magneto ignition<br />

for motor vehicle<br />

engines<br />

High-voltage<br />

magneto ignition<br />

system with spark<br />

plug<br />

Buzz ignition coil Ignition distributor Magneto-generator<br />

ignition unit

<strong>Bosch</strong> <strong>Automotive</strong> | 11<br />

ignition energy via a cable to the spark<br />

plugs, whose electrodes produced the<br />

ignition spark. Electricity was supplied<br />

by the existing on-board network, with<br />

its generator and battery. One of the first<br />

cars to be equipped with this system as<br />

a standard feature was a four-cylinder<br />

passenger car made by the Berlin-based<br />

carmaker NAG (Nationale Automobil-<br />

Gesellschaft).<br />

Battery ignition takes hold<br />

At first, expensive sedans made by Horch<br />

or Maybach continued to feature magneto<br />

ignition systems, since the price of the<br />

ignition system was not so important in<br />

cars of this price category. By the middle<br />

of the 1930s, however, battery ignition<br />

had also finally established itself in this<br />

area. Indeed, as early as 1930, 36 out<br />

of 55 German car models had battery ignition.<br />

It was only in aviation that magneto<br />

ignition kept its prime role. Its independence<br />

of any source of current was the main<br />

argument in favor of this ignition system.<br />

Magneto ignition remained dominant until<br />

the end of the heyday of piston-driven<br />

aero-engines in the 1960s. It was not<br />

needed for jet engines.<br />

Bottom left:<br />

Internationally, <strong>Bosch</strong><br />

ignition systems soon<br />

found favor with vehicle<br />

manufacturers, including<br />

Indian, the legendary U.S.<br />

maker of motorcycles<br />

(1921).<br />

Bottom right:<br />

The “Red Devil,” a stylized<br />

figure based on the<br />

racing driver Camille<br />

Jenatzy, was also used<br />

in advertisements linked<br />

with specific makes, in<br />

this case Ford (1917).<br />

1925 1926 1932 1932 1964<br />

Battery ignition Dynamo-battery<br />

ignition unit<br />

Combined generator,<br />

starter, and ignition<br />

unit<br />

Flywheel-triggered<br />

magneto-generator<br />

ignition unit<br />

Breaker-triggered<br />

TI transistorized<br />

ignition<br />

1965<br />

Breaker-triggered<br />

high-voltage CDI<br />

capacitor-discharge<br />

ignition

12 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

New ignition systems<br />

<strong>Automotive</strong> ignition systems also continued<br />

to evolve. In the 1950s, the automobile<br />

business began to use semiconductor<br />

devices – the predecessors of today’s<br />

electronic components – as standard<br />

equipment. In 1958, <strong>Bosch</strong> had installed<br />

its first electronic device in a <strong>product</strong> – a<br />

Variode regulator for a generator. Then, in<br />

1964, ignition followed the trend – with<br />

transistors that allowed maintenance-free<br />

ignition. The main aim in all this was to<br />

make the periods between service stops<br />

longer and, in the long term, to have cars<br />

that could be driven 100,000 km without<br />

the need for a major service – with the<br />

exception of such indispensable things as<br />

oil changes, of course. The ball was now<br />

rolling, and the changing of ignition contacts<br />

was a thing of the past. At the same<br />

time, the foundation stone had been laid<br />

for the development of today’s electronic<br />

ignition systems, which are not only maintenance-free,<br />

but whose precise management<br />

allows compliance with the strictest<br />

emissions standards and a significant<br />

reduction in fuel consumption.<br />

Transistorized ignition was the first step<br />

in this direction, and was followed by a<br />

variant in which the mechanical contact<br />

was replaced by an electronic pulse generator,<br />

known as the Hall generator. From<br />

then on, there was no need for the ignition<br />

distributor contact, which was prone to<br />

wear. Today, the high voltage is commonly<br />

generated by individual coils, which transmit<br />

power directly to the spark plugs. But<br />

in all this, one thing has remained unchanged.<br />

Even today, no gasoline engine<br />

will run without the ignition spark that<br />

<strong>Bosch</strong> brought into the car.<br />

1974 1979 1982 1983 1987 1989<br />

Maintenance-free,<br />

breakerless TI-i<br />

transistorized<br />

ignition<br />

Motronic<br />

(combination of<br />

L-Jetronic gasoline<br />

injection and<br />

electronic ignition)<br />

Electronic mapcontrolled<br />

ignition<br />

Electronic ignition<br />

with knock control<br />

Electronic ignition<br />

with adaptive knock<br />

control<br />

Motronic with 16-bit<br />

microprocessor

<strong>Bosch</strong> <strong>Automotive</strong> | 13<br />

Far left:<br />

The Junkers W 33 flown by Hünefeld, Köhl,<br />

and Fitzmaurice in the first East-West<br />

crossing of the Atlantic was equipped with<br />

the <strong>Bosch</strong> magneto ignition system (1928).<br />

Left:<br />

The <strong>Bosch</strong> spares kit with replacement<br />

spark plugs and ignition contacts was<br />

popular with all truck drivers (1955).<br />

<strong>Bosch</strong> ignition systems<br />

The beginnings<br />

The principle of magneto ignition has been around since 1866. It was<br />

initially designed for stationary engines. <strong>Bosch</strong> first manufactured its own<br />

magneto ignition device in 1887. First use in the automobile in 1897.<br />

Development <strong>history</strong><br />

Reliable, with a long service life, and suitable for universal use in all<br />

common engines, it was the standard automotive ignition system until<br />

c 1930. From 1925 on, it was displaced by more cost-efficient, batterybased<br />

systems. Today, battery ignition is still the basis for all automotive<br />

ignition systems.<br />

How it works<br />

The air-fuel mixture is ignited in the combustion chamber. The ignition spark<br />

was initially triggered by a break in an electric circuit, and then by a luminous<br />

spark discharge between two spark-plug electrodes under high voltage.<br />

First use<br />

Used on stationary engines from 1887, on a trial basis in a De Dion-Bouton<br />

three-wheeler in September 1897, and in small-series <strong>product</strong>ion for Daimler<br />

trucks (Phoenix) from 1898.<br />

The present day<br />

Today, ignition systems made by <strong>Bosch</strong> are an integral part of electronic<br />

engine management systems for gasoline engines. Called “Motronic,” these<br />

systems regulate injection and ignition by means of a single central control<br />

unit. This business unit is now part of the Gasoline Systems (GS) division.<br />

1989 1996 1998 2001 2004 2007<br />

Static high-voltage Motronic in micro-<br />

Rod coil<br />

Mini Compact<br />

distribution<br />

hybrid design<br />

rod coil<br />

Cylinder-head<br />

module with complete<br />

integrated<br />

ignition<br />

Power Mini Compact<br />

rod coil

14 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

“Safe night-time driving at last!”<br />

<strong>Bosch</strong> automotive lighting systems<br />

Picture with the <strong>Bosch</strong><br />

searchlight, used for<br />

advertising purposes<br />

(1925)

<strong>Bosch</strong> <strong>Automotive</strong> | 15<br />

Up until 1913, <strong>Bosch</strong> manufactured practically nothing but ignition devices<br />

or systems. This focus on a single <strong>product</strong> was a very risky business strategy.<br />

At the same time, the automotive market was changing – the vehicles on the<br />

road were no longer simply luxury vehicles and sports cars, but also articles of<br />

everyday use. Robert <strong>Bosch</strong> recognized that the prospects for electrical automotive<br />

lighting were good. Development work started in 1910, and the <strong>Bosch</strong><br />

automotive lighting system was ready for series <strong>product</strong>ion in 1913. The system<br />

comprised headlights, a generator, a battery, and a regulator. This lighting<br />

system paved the way for <strong>Bosch</strong> as a universal automotive supplier and formed<br />

the basis for today’s vehicle electrical systems.<br />

In 1912, the only <strong>product</strong>s <strong>Bosch</strong> manufactured<br />

were magneto ignition systems,<br />

spark plugs, and <strong>Bosch</strong> oilers. By that time,<br />

the company’s workforce already exceeded<br />

four thousand, and global sales were in the<br />

region of 33 million German marks. More<br />

than 83 percent of sales were generated<br />

outside Germany, a figure that rose to 88<br />

percent just one year later. However, Robert<br />

<strong>Bosch</strong> was aware that such a narrow <strong>product</strong><br />

base was not a healthy situation for a<br />

company of this size. Focusing solely on the<br />

main sales driver – magneto ignition systems<br />

– made the future unpredictable. If<br />

the automotive industry switched to diesel<br />

or electric drives, for example, magneto<br />

ignition systems would no longer be needed.<br />

An urgent task<br />

There were many good reasons to push<br />

ahead with the development of electrical<br />

automotive lighting for series <strong>product</strong>ion.<br />

First, motor vehicles were also widely used<br />

for commercial purposes after around 1910<br />

and needed to be available at any time,<br />

day or night. Second, electrical lighting<br />

was already standard equipment in the<br />

U.S. – the world’s largest automotive market.<br />

Third, regulations such as the requirement<br />

in Germany to equip all motor vehicles<br />

with two headlights from 1909 and similar<br />

laws in neighboring countries created the<br />

basis for a rapid spread of this technology<br />

in Europe as well. And fourth, the carbide<br />

and acetyl lighting common at the time was<br />

Top from left to right:<br />

Milestones of an evolution.<br />

<strong>Bosch</strong> headlights<br />

on a fire truck (1919),<br />

on a Horch (1924), and<br />

on an Opel Olympia<br />

Rekord (1957)

16 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

The <strong>Bosch</strong> automotive lighting system<br />

comprised headlights, generator, battery,<br />

and regulator. It formed the basis for<br />

today’s vehicle electrical systems.<br />

not really suitable for everyday use. Its light<br />

output was far inferior to electrical lighting.<br />

What’s more, the driver had to use a complicated<br />

procedure to ignite and extinguish<br />

the light.<br />

<strong>Bosch</strong> as a systems supplier<br />

Electrical lighting needed a current, but<br />

this was something a battery could only<br />

supply for a limited period of time. Robert<br />

<strong>Bosch</strong>’s idea was to use a generator to<br />

produce sufficient energy to provide a constant<br />

supply to the battery, where it was<br />

stored and transmitted to the headlights.<br />

The heart of the system was thus the generator<br />

for providing electric current. In the<br />

form of the alternator, this is still the basis<br />

of today’s vehicle electrical systems. <strong>Bosch</strong><br />

produced the headlights, generator, and<br />

regulator (then known as a “regulator<br />

box”) in-house. At first, the battery was<br />

purchased from other manufacturers, but<br />

a switch was made to in-house <strong>product</strong>ion<br />

in 1922. The launch of the <strong>Bosch</strong> automotive<br />

lighting system was a milestone for <strong>Bosch</strong>.<br />

In the past, <strong>Bosch</strong> had offered individual<br />

components such as magneto ignition<br />

devices. The <strong>Bosch</strong> automotive lighting<br />

system, by contrast, was an all-in-one system<br />

that saved customers the irksome task<br />

of piecing together the parts they needed.<br />

Instead, they now got all they needed from<br />

a single source, and could be sure that all<br />

the parts were perfectly matched. It is<br />

Milestones<br />

1913 1930 1935 1935 1939 1952<br />

<strong>Bosch</strong> automotive<br />

lighting system,<br />

comprising headlights,<br />

a generator,<br />

and a regulator<br />

Fog lights<br />

Long-range<br />

headlights<br />

Fitted headlights Headlight aiming<br />

device<br />

Quartz vapor-coated<br />

headlight reflector

<strong>Bosch</strong> <strong>Automotive</strong> | 17<br />

evidence of considerable foresight that<br />

this idea of producing systems – a concept<br />

essential to <strong>Bosch</strong> as an automotive supplier<br />

today – was already mapped out in<br />

1913.<br />

Completion of the range, innovations<br />

After 1921, <strong>Bosch</strong> added <strong>product</strong>s specifically<br />

for motorcycles to what was now an<br />

extremely successful range. From 1923,<br />

even bicycles were catered for. These<br />

<strong>product</strong>s were followed in the 1930s by<br />

further special applications such as fog<br />

lights, long-range headlights, tail lights,<br />

and brake lights. <strong>Bosch</strong> became the world’s<br />

leading manufacturer of vehicle lighting,<br />

introducing new developments that we take<br />

for granted today. Examples included lowbeam<br />

headlights, which illuminated the<br />

road ahead without blinding oncoming<br />

traffic; fitted headlights that were perfectly<br />

integrated in the front of the car, both<br />

visually and aerodynamically; asymmetrical<br />

lighting, which illuminated the driver’s side<br />

of the road more than the other side and<br />

thus reduced glare for oncoming traffic;<br />

halogen lights with a 50 percent higher<br />

light output than double-filament lamps;<br />

and finally Litronic for gaseous-discharge<br />

lamps, an electronically controlled system<br />

with increased light output, reduced energy<br />

consumption, and a longer service life.<br />

Left to right:<br />

Brochures for the<br />

<strong>Bosch</strong> automotive<br />

lighting system, with<br />

the advertising motifs<br />

designed by the Stuttgartbased<br />

artist Lucian<br />

Bernhard, underscore<br />

the early significance<br />

of business outside<br />

Germany for <strong>Bosch</strong>.<br />

1957 1957 1966 1971 1986 1991<br />

Low- and high-beam Headlights for<br />

headlights, sidemarker<br />

lights, parking low-beam light<br />

asymmetrical<br />

lights, and turn<br />

signals in one unit<br />

Headlights with H1<br />

halogen light<br />

Headlights with H4<br />

two-filament bulb<br />

Polyellipsoid<br />

headlights<br />

Litronic headlight<br />

system with gaseousdischarge<br />

lamp

18 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

Top:<br />

Extensive tests in<br />

the light channel<br />

also helped <strong>Bosch</strong> to<br />

improve light output<br />

(1930).<br />

End of a long era<br />

In 1999, the <strong>Bosch</strong> Lighting Technology<br />

division was transferred to <strong>Automotive</strong><br />

Lighting GmbH, a joint venture with the<br />

Italian company Magneti Marelli S.p.A.<br />

<strong>Bosch</strong> gradually scaled down its interest<br />

in this joint venture and was no longer<br />

involved at all by 2003. So what remains<br />

of the <strong>Bosch</strong> automotive lighting system<br />

introduced in 1913? The generator for one.<br />

Now in the form of an alternator, it is an<br />

integral part of the vehicle electrical system<br />

and is essential for the operation of electrical<br />

consumers ranging from airbag control<br />

to ignition systems. This is not all. Other<br />

<strong>Bosch</strong> <strong>product</strong>s still ensure good visibility<br />

to this day. The infrared technology of the<br />

“Night Vision” driver assistance system, for<br />

example, enables drivers to see obstacles<br />

sooner than they would with conventional<br />

lights at night.<br />

1993 1995 1996 1998<br />

Headlights with<br />

homogeneous<br />

reflector surface<br />

Headlights with<br />

variable light<br />

distribution<br />

Dynamic headlight<br />

leveling control<br />

Bi-Litronic for<br />

low- and high-beam<br />

headlights

<strong>Bosch</strong> <strong>Automotive</strong> | 19<br />

<strong>Bosch</strong> automotive lighting systems<br />

The beginnings<br />

The <strong>Bosch</strong> automotive lighting system, comprising headlights, a generator,<br />

a regulator, and a battery. Marketed from 1913 on. It replaced the carbide<br />

and acetyl lighting that was commonly used up to that time, which required<br />

considerable maintenance and had a relatively weak output.<br />

Development <strong>history</strong><br />

For everyday use, motor vehicles need reliable lighting. The electrical system<br />

developed by <strong>Bosch</strong> quickly became the most favored solution. To make<br />

vehicles more visible at night and in adverse weather conditions, <strong>Bosch</strong><br />

developed tail lights, position lights, fog lights, and later even tailor-made<br />

lighting systems for all common vehicle models.<br />

How it works<br />

A filament bulb in a reflector housing illuminates the road, drawing its current<br />

from a battery. The battery is fed by a generator that receives dynamoelectric<br />

power when the crankshaft of the running engine turns. A regulator<br />

ensures an even supply of power to the battery.<br />

First use<br />

Developed from 1910 on; first use in <strong>product</strong>ion automobiles in 1913 and<br />

for motorcycles from 1921 on; bicycle lights from 1923 on.<br />

Bottom left:<br />

Around 1950, integrated<br />

headlights were a sign<br />

of modernity. The<br />

Volkswagen Beetle shown<br />

here has all its status<br />

symbols at the front:<br />

fog lights and two supertone<br />

horns, all made by<br />

<strong>Bosch</strong>.<br />

Bottom right:<br />

The “Litronic” lighting<br />

system with gaseousdischarge<br />

lamps was<br />

available in the BMW 7<br />

Series from 1991. Twoand-a-half<br />

times brighter<br />

than halogen light, and<br />

with a light color similar<br />

to daylight, it improved<br />

road safety by ensuring<br />

better illumination.<br />

The present day<br />

Generators are now called alternators and are produced in their millions<br />

at a number of plants. Today, this <strong>product</strong> area belongs to the <strong>Bosch</strong> Starter<br />

Motors and Generators division (SG). The <strong>Bosch</strong> Lighting Technology division,<br />

which produced headlights and lamps, was gradually spun off between<br />

2001 and 2003.

20 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

Well equipped, whatever the weather<br />

Equipment for day-to-day driving

<strong>Bosch</strong> <strong>Automotive</strong> | 21<br />

In 1900, Robert <strong>Bosch</strong> had a range of twelve different <strong>product</strong>s for motor<br />

vehicles – all of them variants of the magneto ignition device. One hundred<br />

years later, this number had risen to more than 355,000 <strong>product</strong> variants. This<br />

diversity is a response to the increasing variety of different vehicle models, as<br />

well as to how customers expect modern vehicles to be equipped. Magneto<br />

ignition was the first step on the company’s path to becoming an automotive<br />

supplier. However, it was not until 1913 and the <strong>Bosch</strong> automotive lighting system<br />

that a battery and a generator guaranteed a reliable supply of electricity.<br />

This was the basis for an on-board electrical system to which numerous other<br />

components – such as a starter, horn, windshield wipers, direction indicators,<br />

and a car heating system – could be connected.<br />

After laying the foundation with magneto<br />

ignition and the <strong>Bosch</strong> automotive lighting<br />

system, <strong>Bosch</strong> went on to expand its expertise<br />

as an automotive supplier step by step.<br />

One particular example of this process is<br />

the electric starter, which became rapidly<br />

widespread in the U.S. after 1910, even<br />

being fitted as standard equipment in<br />

some cars. The starter with an overrunning<br />

clutch made by the U.S. manufacturer<br />

Rushmore was a very promising concept.<br />

<strong>Bosch</strong> bought the company, together with<br />

all rights to manufacture these starters,<br />

in 1914. It was determined to turn the<br />

impressive idea into a high-quality, reasonably<br />

priced <strong>product</strong> that could be produced<br />

in large volumes. <strong>Bosch</strong> subsequently also<br />

used other starter designs, but in the beginning<br />

its sole objective was to find the fastest<br />

way of entering this area of business.<br />

Electric starters made life considerably<br />

easier for motorists. Firstly, drivers were<br />

spared the strenuous task of cranking up<br />

the car. Secondly, after 1900 there was a<br />

significant rise in the number of people who<br />

wanted to drive their own car, but were not<br />

prepared to crank up the car themselves.<br />

Thirdly, when cranking up the car, there<br />

was a risk that the starter crank could fly<br />

back in the opposite direction. This was<br />

known as “crank kickback” and led to<br />

numerous fatal accidents. The electric<br />

starter, on the other hand, was initially<br />

activated at the press of a pedal and later<br />

at the touch of a button. This made it an<br />

innovation with a real future.<br />

Left:<br />

With this Mercedes 170,<br />

engineers tested automotive<br />

lighting, signaling<br />

equipment such as turn<br />

signals and direction<br />

indicators, and electric<br />

horns (1954).

22 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

Motorization fuels demand<br />

The starter has the features typical of<br />

many <strong>product</strong>s brought to market by <strong>Bosch</strong><br />

in the period between the first world war<br />

and the first crisis in the automobile industry<br />

in 1926. Their aim was to eliminate the<br />

shortcomings in operation and safety that<br />

were coming to light as motorization really<br />

took hold. Wherever these shortcomings<br />

became apparent, Robert <strong>Bosch</strong> looked for<br />

new ideas that he then optimized, or inventions<br />

were made in-house that were then<br />

developed until they were ready for series<br />

<strong>product</strong>ion. The manually operated rubber<br />

wiper, developed by Prince Heinrich of<br />

Prussia, became the electric windshield<br />

wiper, the electric horn replaced the rubber<br />

bulb horn, and car heating systems consigned<br />

the hand warmers and long johns<br />

resorted to in the winter to the <strong>history</strong><br />

books. Finally, the direction indicator – or<br />

turn signals, as they have been known<br />

since 1949 – carried out the function<br />

previously performed by the driver‘s<br />

outstretched arm.<br />

Many of these <strong>product</strong>s – such as the<br />

horn, the windshield wiper, and the turn<br />

indicator – can be attributed to the work<br />

of Gottlob Honold, who also developed<br />

high-voltage magneto ignition. He was<br />

the company’s first head of development,<br />

setting up a department whose potential<br />

quickly became clear to <strong>Bosch</strong>. There are<br />

currently some 33,000 people working in<br />

research and development at <strong>Bosch</strong>, and<br />

this department was where it all started.<br />

Diesel and gasoline engine management<br />

In the era up until the 1920s, the automotive<br />

business sector was dominated by<br />

electrical components. However, <strong>Bosch</strong><br />

It was not only the manufacturers of<br />

stolid family sedans that favored <strong>Bosch</strong>.<br />

Exclusive carmakers such as Bentley and<br />

Bugatti also opted for the southwest<br />

German automotive supplier (c 1935).

<strong>Bosch</strong> <strong>Automotive</strong> | 23<br />

also built up other new areas. Injection<br />

technology for gasoline and diesel engines<br />

was one of these, with components including<br />

an injection pump, a governor, and<br />

nozzles. Electronic control units and sensors<br />

were also made available for injection<br />

systems from the late 1960s on. These<br />

areas of activity are now critical to the<br />

company’s operations. Today, <strong>Bosch</strong> has<br />

two divisions devoted to gasoline and<br />

diesel injection systems.<br />

As early as 1909, <strong>Bosch</strong> had already mastered<br />

the basic technology for fuel metering<br />

with the <strong>Bosch</strong> oiler. This was a lubricating<br />

pump that enabled precise metering and<br />

distribution of lubricants under high pressure<br />

in stationary and large vehicle engines,<br />

and thus performed the very task called<br />

for in fuel injection technology. However,<br />

the road to diesel injection was a long and<br />

difficult one. Manufactured from 1927, it<br />

entered the market in 1928, albeit initially<br />

only for trucks. Diesel components for<br />

passenger cars followed in 1936.<br />

Unlike diesel injection, gasoline injection<br />

was at first developed solely for use in<br />

aircraft. It did not serve the road vehicle<br />

market until after the second world war,<br />

when the advantages it offered in terms<br />

of consumption, efficiency, and emissions<br />

matched the new market requirements.<br />

By contrast, the <strong>product</strong>ion of carburetors<br />

in the early 1930s was a marginal episode<br />

in the <strong>history</strong> of <strong>Bosch</strong>, which it soon discontinued.<br />

Since the beginnings of automobile<br />

development, carburetors had been<br />

the dominant system for air-fuel mixture<br />

formation in gasoline engines (indeed, for<br />

a while, they were the only such system).<br />

<strong>Bosch</strong>, though, branched off in new directions.<br />

Specialists at the company recognized<br />

the potential of injection systems<br />

for automobiles long before they appeared<br />

on the market.<br />

Networking functions and international<br />

development work<br />

<strong>Bosch</strong> has always invested significant time<br />

in researching, developing, and testing<br />

all areas of automotive technology before<br />

taking <strong>product</strong>s into series <strong>product</strong>ion.<br />

But a new dimension of development has<br />

come to the fore over the past three decades.<br />

Right from the very start, engineers<br />

now look into the possibility of networking<br />

functions. And rightly so, since today’s<br />

complex electronic systems would be<br />

unthinkable without networking. Sensor<br />

Top left:<br />

In order to show other<br />

road users which way<br />

the driver wanted to go,<br />

<strong>Bosch</strong> developed the<br />

direction indicator in<br />

1928. From 1949, it was<br />

displaced by the turn<br />

signal that is common<br />

today.<br />

Top right:<br />

This advertising motif<br />

from 1926 promises clear<br />

visibility with the new<br />

<strong>Bosch</strong> windshield wiper.

24 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

data – from the brake control system, for<br />

example – can now be utilized for the functions<br />

of other systems. The control system<br />

of the ESP® electronic stability program,<br />

for instance, can intervene in engine management<br />

and reduce engine power if the car<br />

shows signs of skidding. And as a further<br />

way of preventing hazardous situations, the<br />

brake system can utilize the radar data from<br />

the adaptive cruise control system. It can<br />

then either perform automatic emergency<br />

braking or, if impact is unavoidable, can<br />

protect occupants by activating the airbags<br />

faster.<br />

As late as the 1960s, <strong>Bosch</strong> automotive<br />

technology was still developed exclusively<br />

in Germany. To a large extent, it was also<br />

produced there. This situation has changed<br />

fundamentally over the past five decades.<br />

Today, <strong>Bosch</strong> has manufacturing sites on all<br />

continents of the world. By comparison, the<br />

development of <strong>Bosch</strong> <strong>product</strong>s in various<br />

countries outside Germany is relatively new.<br />

Developing <strong>product</strong>s in this way enables<br />

components and complete systems to be<br />

developed to meet specific market and<br />

regional requirements. The engine management<br />

system for a premium-class vehicle<br />

in Europe, for example, must meet highest<br />

quality standards in terms of performance,<br />

comfort, and handling. An inexpensive<br />

compact car in India or China, on the other<br />

hand, calls for basic functions at low cost<br />

and robust components that can cope with<br />

widely varying qualities of fuel and longterm<br />

operation on bumpy roads. This, too,<br />

calls for state-of the art technology. It’s just<br />

another way of looking at it.<br />

A divisional structure emerges<br />

The increasing complexity and variety of<br />

components is reflected in the ongoing<br />

development of the organizational structure<br />

of the units that develop, test, manufacture,<br />

and market them. In 1959, a divisional<br />

structure was introduced at <strong>Bosch</strong>.<br />

The divisions are responsible for certain<br />

Milestones<br />

1897 1902 1909 1913 1914 1921<br />

Magneto ignition<br />

device for automobiles<br />

Lubricating pump<br />

(oiler)<br />

Starter<br />

Horn<br />

High-voltage<br />

magneto ignition<br />

system with<br />

spark plug<br />

Headlights, voltage<br />

regulator, generator<br />

(<strong>Bosch</strong> automotive<br />

lighting system)

<strong>Bosch</strong> <strong>Automotive</strong> | 25<br />

Far left:<br />

With his half-helmet and goggles, this<br />

friendly motorcyclist extols the virtues<br />

of the <strong>Bosch</strong> battery (1960).<br />

Left:<br />

<strong>Bosch</strong> offers a whole range of <strong>product</strong>s<br />

for unhampered driving in the winter and<br />

fall (1954).<br />

<strong>product</strong> areas. While they have entrepreneurial<br />

independence, they work<br />

closely with the board of management.<br />

The <strong>Automotive</strong> Technology business<br />

sector comprises the following divisions:<br />

Gasoline injection<br />

The Gasoline Systems (GS) division<br />

develops, manufactures, and markets<br />

systems and components needed for<br />

gasoline engines, such as engine control<br />

units, fuel pumps for intake-manifold and<br />

direct injection, injection valves, sensors,<br />

ignition coils, and spark plugs. This division<br />

is also responsible for the development<br />

of hybrid drives, all-electric vehicle<br />

drive systems, and components for the<br />

control of automatic transmissions.<br />

Diesel injection<br />

The Diesel Systems (DS) division develops,<br />

manufactures, and markets systems and<br />

components for the management of diesel<br />

engines, such as engine control units,<br />

high-pressure pumps, high-pressure<br />

rails, and injection valves for commonrail<br />

diesel injection systems, as well as<br />

conventional in-line and distributor<br />

injection pumps. Over recent years,<br />

exhaust-gas treatment systems for both<br />

passenger cars and commercial vehicles<br />

have been added to the portfolio.<br />

Brakes and chassis<br />

The Chassis Systems Brakes (CB) and<br />

Chassis Systems Control (CC) divisions<br />

develop, manufacture, and market chassis<br />

components such as brakes and brake<br />

actuation and control systems. These range<br />

from the ABS antilock braking system to<br />

the ESP® electronic stability program,<br />

driver assistance systems based on radar<br />

and video, and passive safety systems<br />

such as airbag control units.<br />

1922 1924 1925 1926 1926 1927<br />

Battery<br />

Auxiliary starting<br />

system<br />

Battery ignition Windshield wipers Dynamo-battery<br />

ignition unit<br />

Diesel injection<br />

pump, injection<br />

nozzle

26 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

Energy and comfort<br />

The Electrical Drives (ED) division develops,<br />

manufactures, and markets <strong>product</strong>s relating<br />

to body electrics and electronics. These<br />

include components required for wiping<br />

the windshield, for cooling the engine, for<br />

regulating the temperature in the vehicle<br />

interior, and for adjusting windows and<br />

seats.<br />

Engine start and energy generation<br />

The Starter Motors and Generators (SG)<br />

division develops, manufactures, and markets<br />

alternators as well as electric starters<br />

for vehicles of all sizes. These components<br />

generate the energy required for electrical<br />

consumers such as the lights or ignition<br />

system. The division’s <strong>product</strong>s also include<br />

start-stop systems, which reduce fuel consumption.<br />

Car multimedia<br />

The Car Multimedia (CM) division develops,<br />

manufactures, and markets entertainment,<br />

navigation, and driver information <strong>product</strong>s<br />

as original equipment for cars, ranging from<br />

conventional car radios through to complex<br />

navigation systems.<br />

<strong>Automotive</strong> electronics<br />

The <strong>Automotive</strong> Electronics (AE) division<br />

develops, manufactures, and markets semiconductor<br />

<strong>product</strong>s such as microchips and<br />

sensors, as well as entire electronic control<br />

units for systems developed by other divisions.<br />

Products for the end customer<br />

The <strong>Automotive</strong> Aftermarket (AA) division<br />

markets automotive engineering <strong>product</strong>s<br />

to the trade and end customers. This is a<br />

single source where the car-parts trade<br />

and workshops can find everything they<br />

need for their customers. <strong>Bosch</strong> spare parts<br />

for every segment, testing equipment, and<br />

1927 1927 1928 1928 1930 1930<br />

Shock absorbers Vacuum brakes Brake support Direction<br />

Fuel filter<br />

Fog lights<br />

indicators

<strong>Bosch</strong> <strong>Automotive</strong> | 27<br />

From the 1930s on, <strong>Bosch</strong> published slim<br />

brochures listing the recommended <strong>Bosch</strong><br />

components for common vehicle models.<br />

From 1952, the brochures were published<br />

in color, too. The examples shown here are<br />

brochures for the Opel Olympia Rekord,<br />

Peugeot 203, and Renault 4CV from the<br />

period 1952 to 1957.<br />

Equipment for day-to-day driving – the early years<br />

The beginnings<br />

After the magneto ignition and the <strong>Bosch</strong> automotive lighting system, <strong>Bosch</strong><br />

extended its range of <strong>product</strong>s for everyday driving. New developments<br />

included the electric starter (1914), followed by the horn (1921), windshield<br />

wipers (1926), and direction indicators (1928). <strong>Bosch</strong> became a one-stop<br />

supplier for automotive electrics – and from 1927 on, for brakes and diesel<br />

injection as well.<br />

Development <strong>history</strong><br />

After the first world war, automobiles increasingly became less of a luxury<br />

and more an everyday <strong>product</strong>. When it rained, the windshield had to be<br />

wiped, and when it was dark, the vehicle needed lights to make it visible<br />

and illuminate the road. A horn and indicators became essential for warning<br />

other road-users and indicating direction. <strong>Bosch</strong> responded to these market<br />

needs, and in so doing created further areas in which the company could<br />

do business.<br />

know-how are available round the clock<br />

all over the world, for every make of car.<br />

<strong>Bosch</strong> Car Service workshops will service,<br />

diagnose faults in, and repair even the most<br />

modern vehicles. This division also manages<br />

the worldwide technical after-sales service<br />

for vehicle <strong>product</strong>s and systems. The<br />

division therefore ensures that all common<br />

<strong>Bosch</strong> components can always be replaced,<br />

even if the cars for which they were made<br />

have not been built for many years now.<br />

In addition, the “<strong>Automotive</strong> Tradition”<br />

department provides vintage car owners<br />

with parts and expertise. The establishment<br />

of this department in 2005 underpins the<br />

company’s commitment to conserving<br />

important vehicles from the past.<br />

How it works<br />

All the first electrical <strong>product</strong>s replaced mechanical forerunners. The electric<br />

horn replaced the bulb horn, the manually operated wiper gave way to<br />

windshield wipers, direction indicators were used instead of outstretched<br />

arms, and the starter did away with strenuous cranking-up. The aim of these<br />

<strong>product</strong>s was to relieve the burden on drivers, so that they were distracted<br />

as little as possible from their primary task of driving.<br />

First use<br />

The first equipment used included accessories that could be installed in<br />

any vehicle. Initially, each <strong>product</strong> was mainly installed in luxury cars. The<br />

higher the <strong>product</strong>ion volumes, the cheaper and more common the <strong>product</strong>s<br />

became. From about 1930 onward, all the standard car makes were fitted<br />

with direction indicators, a horn, a starter, and lights as standard equipment.<br />

The present day<br />

Several divisions now develop and manufacture electrical components and<br />

original equipment for new vehicles. These are also available to end customers,<br />

for example in the form of spare parts. <strong>Bosch</strong> today provides almost<br />

every automotive electric function, from power-window motors to airbag<br />

triggering units.<br />

Past and present<br />

In 1900, <strong>Bosch</strong> recorded sales of around<br />

295,000 German marks, with its 12 magneto<br />

ignition models. For all the vehicle<br />

components sold in 2010, this figure was<br />

more than 27 billion euros.<br />

1931 1931 1932 1932 1933 1936<br />

Steering wheels Governor for diesel Combined generator, Car radio<br />

Steering lock Car heating system<br />

injection pumps starter, and ignition<br />

unit<br />

(Blaupunkt)

28 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

<strong>Bosch</strong> engine<br />

management –<br />

not just for<br />

smooth operation<br />

A motor mechanic tests the ignition<br />

system of a Volkswagen Type 1 Beetle<br />

(1954). The EWAF41 engine testing<br />

device could be used to test all common<br />

electrical automotive systems and<br />

components. Apart from the ignition<br />

system, these included the alternator<br />

and the starter.

<strong>Bosch</strong> <strong>Automotive</strong> | 29

30 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

From heavy-oil pumps to<br />

multiple injection<br />

<strong>Bosch</strong> diesel injection systems<br />

In around 1920, experts were vaunting the diesel engine as the drive system<br />

of the future. <strong>Bosch</strong> was quick to latch on to this trend, and 1922 marked<br />

the official start of diesel injection pump development. <strong>Bosch</strong> started series<br />

<strong>product</strong>ion of in-line pumps for trucks on November 30, 1927. Production for<br />

passenger cars started in 1936. In the 1970s, <strong>Bosch</strong> solutions made the diesel<br />

engine a firm feature of the “Golf class.” From the end of the 1990s, highpressure<br />

injection systems such as common rail made the diesel into a highperformance,<br />

eco-friendly engine, as a result of which its market share in<br />

Europe rose to as much as 50 percent.

<strong>Bosch</strong> <strong>Automotive</strong> | 31<br />

Left:<br />

This six-cylinder truck engine<br />

from 1934 is an impressive sight.<br />

It is equipped with a <strong>Bosch</strong><br />

fuel-injection pump.<br />

Right:<br />

The <strong>Bosch</strong> oiler, manufactured<br />

from 1909 on, was one of the<br />

technological pillars on which<br />

diesel injection was based. This<br />

brochure was published in 1914.<br />

Robert <strong>Bosch</strong> first encountered the diesel<br />

engine as early as 1894. At the invitation<br />

of the inventor Rudolf Diesel, the young<br />

entrepreneur visited Augsburg to find out<br />

about this innovative engine design. However,<br />

the issue then was not yet one of<br />

injection systems. Instead, Rudolf Diesel<br />

was interested in <strong>Bosch</strong> magneto ignition,<br />

since the diesel engines of the time still<br />

needed an ignition system. They do not<br />

need any such system now, since in modern<br />

diesel engines the fuel ignites solely as a<br />

result of the high pressures and temperatures<br />

in the combustion chamber.<br />

While the meeting with Rudolf Diesel<br />

came to nothing, the same cannot be said<br />

of <strong>Bosch</strong>’s encounter with this new engine<br />

design. From 1920 on, Robert <strong>Bosch</strong> was<br />

forced to concede that diesel engines were<br />

so well developed that they presented a<br />

serious alternative to gasoline engines in<br />

vehicles. While they had lower specific<br />

power, they also consumed a lot less fuel –<br />

as much as 30 percent less. Robert <strong>Bosch</strong><br />

feared for his main source of revenue – the<br />

magneto ignition system – since it was not<br />

needed in diesel engines. The time had<br />

come to develop components for this prom-

32 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

ising engine concept. <strong>Bosch</strong> had to be sure<br />

that the company was ready for this technological<br />

change and could benefit from the<br />

growth of the diesel market.<br />

who subsequently continued work on the<br />

new <strong>product</strong> on the company’s behalf.<br />

However, disagreements led to his departure<br />

in 1926.<br />

Green light for development<br />

The official go-ahead for the development<br />

of diesel injection equipment was given in<br />

1922. <strong>Bosch</strong> was able to benefit from its<br />

previous experience in the development<br />

of lubricating pumps. These pumps, also<br />

known as <strong>Bosch</strong> oilers, were capable of<br />

delivering precise quantities of fluid under<br />

high pressure to specific points in the<br />

engine – which is virtually what a fuel-injection<br />

pump does. Furthermore, the company<br />

pooled its own know-how with that of other<br />

diesel pioneers. <strong>Bosch</strong> acquired patents<br />

from Franz Lang, a development engineer<br />

As early as 1924, initial trials with <strong>Bosch</strong><br />

injection pumps took place in the first<br />

series-produced diesel trucks in Germany,<br />

and in 1926 <strong>Bosch</strong> delivered the first prototypes<br />

to interested customers in the automotive<br />

industry. The pump was ready for<br />

series <strong>product</strong>ion at the end of 1927. The<br />

<strong>product</strong>ion release for the first 1,000 units<br />

was issued on November 30, 1927, with<br />

the units being delivered to MAN, the first<br />

customer, early the following year. Other<br />

customers were quick to follow. In the<br />

1930s, numerous European manufacturers<br />

equipped their trucks and agricultural<br />

Right:<br />

Sheet-metal advertising<br />

sign for diesel injection<br />

pumps for commercial<br />

vehicles, in a style<br />

common to the 1930s.<br />

Far right:<br />

Poster advertising diesel<br />

injection pumps, using<br />

the traditional advertising<br />

style for <strong>Bosch</strong> spark<br />

plugs (1949).

<strong>Bosch</strong> <strong>Automotive</strong> | 33<br />

machinery with <strong>Bosch</strong> diesel injection<br />

systems. They included Alfa-Romeo, Asap<br />

(Skoda), Basse & Selve, Berliet, Bianchi,<br />

Borgward, Brossel Freres, Büssing, Citroën,<br />

Delahaye, Deuliewag, Fahr, FAMO, Faun,<br />

Gräf & Stift, Güldner, Hanomag, Henschel,<br />

Hürlimann, Isotta-Fraschini, Kaelble,<br />

Klöckner-Humboldt-Deutz, Krupp, Lanz,<br />

Mercedes-Benz, O.M. Brescia, Peugeot,<br />

Praga, Renault, Saurer, Scania-Vabis,<br />

Schlüter, Tatra, and Vomag. Many of these<br />

truck manufacturers had previously used<br />

designs of their own, but rapidly converted<br />

to the <strong>Bosch</strong> system. This quickly resulted<br />

in a strong market position, which<br />

is reflected in <strong>product</strong>ion volumes: some<br />

100,000 fuel-injection pumps had already<br />

been produced by 1934.<br />

Offering complete systems<br />

For all these manufacturers, <strong>Bosch</strong> supplied<br />

a complete system, comprising injection<br />

pump, fuel lines, fuel-supply pump,<br />

fuel filter, injection nozzles, and nozzleholder<br />

assemblies, as well as glow plugs<br />

for cold-start conditions. Because all these<br />

components were delivered from a single<br />

source, <strong>Bosch</strong> could rule out difficulties<br />

in getting the systems to work. All the<br />

<strong>product</strong>s were carefully designed to work<br />

together. In 1931, a further innovation<br />

arrived in the shape of the diesel governor.<br />

This guaranteed optimum fuel metering in<br />

any driving mode – from idling to full throttle.<br />

The range of injection equipment grew<br />

both quickly and systematically. Not only<br />

trucks and tractors were equipped with<br />

Advertisement celebrating the<br />

two-millionth <strong>Bosch</strong> diesel injection<br />

pump (1952). This is a very rare<br />

motif, since the diesel systems unit<br />

at <strong>Bosch</strong> traditionally supplied<br />

original equipment for new vehicles<br />

and therefore seldom advertised its<br />

own <strong>product</strong>s.

34 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

Bottom left:<br />

The Mercedes-Benz 260 D<br />

was the first car in the<br />

world to feature diesel<br />

injection as standard<br />

(1936).<br />

Bottom right:<br />

From 1960, <strong>Bosch</strong><br />

supplied the first<br />

distributor injection<br />

pumps. The Peugeot<br />

404 Diesel was the<br />

first car to feature<br />

this pump (1964).<br />

<strong>Bosch</strong> diesel injection systems, but also<br />

diesel locomotives, ships, airships, and<br />

even airplanes.<br />

<strong>Bosch</strong> was initially unable to enter the<br />

most lucrative <strong>product</strong> area of all – injection<br />

systems for passenger cars. Injection<br />

pumps were too large for this application,<br />

while smaller engines with smaller pumps<br />

would not have been powerful enough.<br />

But <strong>Bosch</strong> was also working in this area,<br />

and in 1927, unbeknown to the public, a<br />

sedan with a Stoewer engine converted<br />

to <strong>Bosch</strong> diesel technology clocked up<br />

more than 40,000 kilometers.<br />

It was not until 1936, however, that the<br />

first manufacturers ventured onto the<br />

market. Mercedes-Benz presented its<br />

260 D car and Hanomag a 1.9-liter diesel<br />

car engine, but it was 1938 before the<br />

latter was first installed, in the Hanomag<br />

Rekord. Before the second world war,<br />

however, diesel-powered passenger cars<br />

were not able to catch on. Car buyers<br />

were less interested in economy and more<br />

concerned with noise, vibration, and output<br />

– and these were the areas in which<br />

diesel cars still left much to be desired.<br />

Milestones<br />

1921 1922 1923 1927 1928 1930<br />

Diesel injection<br />

trials using <strong>Bosch</strong><br />

oilers<br />

Official start of<br />

development for<br />

diesel injection<br />

technology<br />

First prototypes<br />

of diesel injection<br />

pumps<br />

Series manufacture<br />

of injection pumps<br />

and nozzles for<br />

commercial vehicles<br />

1,000th diesel<br />

injection pump<br />

10,000th diesel<br />

injection pump

<strong>Bosch</strong> <strong>Automotive</strong> | 35<br />

The commercial success<br />

of the diesel engine in<br />

subcompact and compact<br />

cars dates from<br />

1976, and the VW Golf<br />

Diesel. With its distributor<br />

injection pump,<br />

<strong>Bosch</strong> played a role in<br />

this success.<br />

Market success and new areas of business<br />

A further statistic demonstrates the spread<br />

of the diesel engine after 1945. By 1950,<br />

<strong>Bosch</strong> had manufactured one million units,<br />

and the trend showed no sign of slowing.<br />

At the same time, however, the traditional<br />

in-line pump was large and complex. For<br />

this reason, it was not really suitable for<br />

installation in small engines in inexpensive<br />

small cars. This was why <strong>Bosch</strong> also<br />

focused on distributor pumps from 1960<br />

on. The company was helped by the expertise<br />

of French manufacturers such as Sigma,<br />

but developed these pumps further to<br />

satisfy its own requirements. The Peugeot<br />

404 Diesel, the first car to feature a <strong>Bosch</strong><br />

distributor pump, remained a one-off<br />

project since the pump still had a number<br />

of unresolved design problems. Moreover,<br />

there was still no broad customer base.<br />

Peugeot and Mercedes-Benz were the<br />

only companies manufacturing diesel cars<br />

in any great number. And both still displayed<br />

a preference for in-line pumps. When<br />

Volkswagen started showing an interest in<br />

small, economical diesel cars, however, the<br />

distributor pump’s small size and low price<br />

brought it back into play once again. <strong>Bosch</strong><br />

had never stopped working on improvements<br />

in the design, and had the VE type<br />

pump ready for series <strong>product</strong>ion in good<br />

time. The launch of the Golf Diesel in 1976<br />

marked the start of a veritable boom in the<br />

number of diesel models in the compact<br />

class. Electronic control units were added<br />

to distributor pumps from 1986 and to<br />

1931 1934 1936 1950 1960<br />

Introduction of<br />

injection pump<br />

governor<br />

Pneumatic injection<br />

pump governor and<br />

100,000th diesel<br />

injection pump<br />

Diesel injection<br />

system for<br />

passenger cars<br />

1,000,000th diesel<br />

injection pump<br />

First VM distributor<br />

pump<br />

1975<br />

VE distributor pump

36 | Supplement 2 | Journal of <strong>Bosch</strong> History<br />

Left to right:<br />

A look inside the engine<br />

compartment of an Audi<br />

100 TDI (1989). This<br />

model was the first diesel<br />

car in large-scale series<br />

<strong>product</strong>ion to feature<br />

high-pressure direct<br />

injection. As a result, the<br />

car reached a top speed<br />

of 195 kph, with an average<br />

fuel consumption of<br />

6 liters per 100 km.<br />

Common rail, the diesel<br />

system most frequently<br />

used today, was first<br />

installed in the Alfa<br />

Romeo 156 JTD (1997).<br />

It achieved uniform injection<br />

pressures of up to<br />

1,350 bar. This technology<br />

enabled multiple<br />

injections.<br />

A look inside the combustion<br />

chamber of a modern<br />

four-valve diesel engine<br />

(2008)<br />

in-line pumps from 1987. These ECU’s<br />

optimized emissions, noise, power, and<br />

consumption. Moreover, they enabled<br />

injection systems to be linked with other<br />

electronic systems, such as the traction<br />

control system (TCS), which stops the<br />

wheels spinning by intervening in engine<br />

management or in the brake control system.<br />

<strong>Bosch</strong> used this success to further extend<br />

its competence in both systems – in-line<br />

and distributor pumps. In the case of distributor<br />

pumps, collaboration with Audi<br />

resulted in the first systems capable of<br />

injecting fuel directly into the combustion<br />

chamber at a pressure of almost 1,000 bar.<br />

In combination with turbo-charging, this<br />

made the diesel engines built from 1989<br />

on more economical. The engines also<br />

produced less exhaust gas and helped<br />

vehicles achieve remarkable driving performance.<br />

High-pressure fuel injection<br />

marked the diesel engine’s breakthrough<br />

in Europe.<br />

Common rail and multiple injection<br />

The high proportion of passenger cars<br />

equipped with diesel engines – around<br />

30 percent in western Europe in 2000 –<br />

came about as a result of crucial further<br />

developments in high-pressure dieselinjection<br />

technology. <strong>Bosch</strong> offered a<br />

number of variants, including the radialpiston<br />

distributor pump (1996), the common-rail<br />

system (1997), and unit-injector<br />

technology (1998). They all achieved injection<br />

pressures of up to around 1,500 bar<br />

(and have even exceeded 2,200 bar in<br />

subsequent generations), and were thus<br />

characterized by both economy and performance.<br />

Eventually, the common-rail system won<br />

through. The Fiat subsidiary Elasis was<br />

responsible for the basic idea, but <strong>Bosch</strong><br />

refined the system to make it ready for<br />

series <strong>product</strong>ion. This system offered<br />

crucial advantages over the other two.<br />

Although the peak pressures of the common-rail<br />

system were lower than those<br />

of the unit-injector system (which could<br />

1986 1989 1993 1995 1996 1997<br />

EDC electronic diesel<br />

control system<br />

VP 37 axial-piston<br />

distributor pump<br />

for direct injection<br />

in passenger-car<br />

engines<br />

Control-sleeve fuel<br />

injection pump<br />

Unit-pump system<br />

(UPS)<br />

VP 44 radial-piston<br />

distributor pump<br />

Common-rail system<br />

for passenger-car<br />

engines

<strong>Bosch</strong> <strong>Automotive</strong> | 37<br />

achieve values of well over 2,000 bar and<br />

thus ensured very low consumption levels),<br />

the consistently high pressure at which<br />