VIBROMAX | VMT160 - DEMCO JCB

VIBROMAX | VMT160 - DEMCO JCB

VIBROMAX | VMT160 - DEMCO JCB

- TAGS

- vibromax

- demco

- www.demcojcb.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

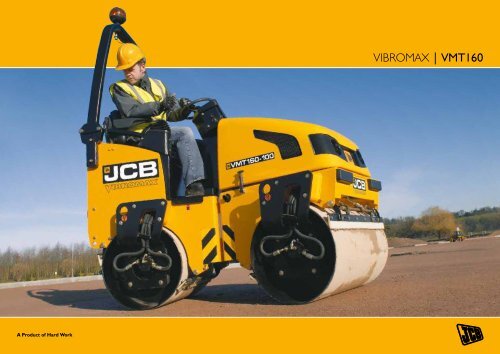

A Product of Hard Work<br />

<strong>VIBROMAX</strong> | <strong>VMT160</strong>

Setting new standards The new <strong>VMT160</strong> tandem rollers are quite simply the most productive machines available in<br />

this high volume sector. In fact, it is safe to say that with this range, <strong>JCB</strong> has established a new<br />

benchmark in choice, comfort, control, reliability, serviceability and performance.<br />

Designed completely from scratch, the <strong>VMT160</strong> range consists of five models: the 160-80,<br />

160-90 and 160-100 have drum widths of 800mm, 900mm and 1000mm respectively, plus the

800mm and 900mm versions are available with Total Side Clearance (<strong>VMT160</strong>-80 TSC and<br />

<strong>VMT160</strong>-90 TSC). All of these models benefit from the inclusion of a class-leading 45-litre<br />

diesel tank combined with a 125-litre water tank. This allows the <strong>VMT160</strong> to work at maximum<br />

capacity for much longer than its nearest rivals, giving you up to a whole day of extra usage.<br />

We have also introduced new, ergonomic seating on a perfectly vibration isolated operator<br />

WORK FLAT OUT FOR UP TO TWICE AS LONG<br />

stand and conveniently positioned, user-friendly controls. So whatever you’re doing (from<br />

rolling sub-base and finish rolling asphalt materials, to patch and repair works) and wherever<br />

you’re doing it (access roads, yards, residential streets, car parks, highways, airports) these<br />

rollers are simplicity itself to operate. Add all of this to <strong>JCB</strong>’s legendary build quality and the<br />

best back up in the business, and you have a range of tandem rollers that just can’t be beaten.

Power and<br />

performance<br />

Largest diesel and water tanks mean you can work flat<br />

out for up to twice as long<br />

Three-cylinder, water-cooled, four-stroke engine<br />

delivers maximum power<br />

Electrically controlled hydrostatic direct drive on both<br />

drums enhances versatility<br />

Superb stability increases operating safety<br />

Total Side Clearance (TSC) does away with need<br />

for separate perimeter tamping<br />

The <strong>JCB</strong> Vibromax VMT range is renowned for its excellent combination of<br />

static weight, centrifugal force, amplitude, tight turning circle and fast rolling<br />

speed. The new <strong>VMT160</strong>s boast these same key qualities as well as adding<br />

greater power, performance and attention to detail into the mix.<br />

Perhaps the most impressive development to have been incorporated into<br />

these machines is the high capacity fuel and water tanks, which enable them<br />

to outperform all the competition when it comes to productivity. The 45-litre<br />

diesel engine tank is nearly double the market average of 24 litres, while the<br />

125-litre water tank is significantly greater than the 90-litre market average.<br />

What this all means is that, based on an average consumption of three litres<br />

per hour, the <strong>VMT160</strong> gives you 7 hours’ extra usage than the competition.<br />

Basically these machines can work flat out for up to twice as long.<br />

All five machines in the range feature a new three-cylinder, water-cooled,<br />

four-stoke engine that delivers maximum power at reduced noise levels.<br />

Electrically controlled hydrostatic direct drive on both drums enables you to<br />

maximise performance on any application by selecting double vibration,<br />

single front vibration or single rear vibration. Plus, <strong>VMT160</strong>s feature<br />

Automatic Vibration Control (AVC) as standard, while exceptional stability<br />

provides optimum operating safety.<br />

Customers can opt for Total Side Clearance (TSC) operation. There are<br />

two models, <strong>VMT160</strong>-80 and <strong>VMT160</strong>-90, in the range are available with<br />

TSC, which enables you to get close up to the edge saving the time often<br />

taken to compact perimeter areas.<br />

Such incredible power and performance, plus the added versatility that comes<br />

from being easily transportable on a trailer (non TSC models weigh 1600-<br />

1700kg), equals a compaction solution that is fast becoming indispensable.

<strong>VMT160</strong> | POWER AND PERFORMANCE

Comfortable,<br />

controllable, reliable<br />

New design for improved operator comfort combined<br />

with extreme robustness<br />

Fully adjustable, spacious seating is accessible from both sides<br />

Excellent manoeuvrability characteristics and fast rolling speeds<br />

Newly designed control layout makes for intuitive operation<br />

Servo driving lever and engine speed control improve controllability<br />

In a sector renowned for the somewhat ‘basic’ design of its equipment,<br />

the new modern styling of the <strong>VMT160</strong> will come as a very welcome<br />

change. These machines are designed with operator comfort and safety<br />

firmly in mind.<br />

The fully adjustable, comfortable and spacious seating position, cup holder<br />

and safety switch, is easily accessible from both sides of the machine. It also<br />

offers a clear view for increased accuracy and safety while work is in progress.<br />

Safety on site is enhanced by a reverse alarm, emergency stop button and<br />

front and rear working lights as standard, with optional foldable or fixed<br />

ROPS frame and a flashing beacon.<br />

The new <strong>VMT160</strong> also features a newly designed control layout, with<br />

simple and clearly labelled controls and an informative indicator dashboard,<br />

making operation much more user friendly. Meanwhile, precision control is<br />

achieved through the servo driving lever and engine speed control.<br />

Furthermore the <strong>VMT160</strong> possesses excellent manoeuvrability characteristics<br />

combined with fast rolling speeds making it a highly flexible machine to cater<br />

for all on-site requirements.<br />

As you would expect from a world-class manufacturer with a reputation for<br />

excellence, the build quality of the <strong>VMT160</strong> models is of the highest standard,<br />

ensuring you maximum durability and reliability. And as for servicing, we’ve<br />

made life easier by reducing maintenance requirements and ensuring all<br />

routine checks are easily accessible.<br />

Power and performance just don’t come in a more comfortable, controllable<br />

or reliable package.

<strong>VMT160</strong> | COMFORTAbLE, CONTROLLAbLE, RELIAbLE

Driver’s Platform<br />

Very spacious, comfortable and adjustable drivers seat with arm rests<br />

as an option<br />

Access from both sides of machine<br />

Optimal visibility<br />

Cup holder<br />

Perfectly vibration isolated<br />

Chassis<br />

Robust and strong, articulated<br />

Heavy duty maintenance free centre joint<br />

+/- 65mm drum offset (optional)<br />

Equal weight distribution (front and rear)<br />

Vibration<br />

High frequency for fast rolling speed<br />

AVC – Automatic Vibration Control<br />

Double, or single-front, or single-rear vibration<br />

Components<br />

High quality, reliable components<br />

Proven over many years<br />

Powerful, water-cooled and low-noise diesel engine<br />

Service Access<br />

100% access to all components under lightweight hood, electrics<br />

in steering column<br />

Water Sprinkler System<br />

2 solid steel spray bars on each drum<br />

Changeable nozzles with excellent service access<br />

Pressurised water system<br />

Largest water tank in the industry of 125 litres<br />

Lockable water filler<br />

Blue lockable water filler cap<br />

brakes<br />

Spring-applied, hydraulically released parking brakes on<br />

each drum<br />

Scrapers<br />

2 per drum<br />

Spring loaded for optimised use and<br />

prolonged life<br />

Drums<br />

Strong and reliable vibration and drive motors<br />

Oil splash lubricated exciter shaft bearings<br />

Hydrostatic propulsion and vibration on both drums<br />

Machined drum surfaces for concentricity<br />

Single piece circular exciter for long life

<strong>VMT160</strong> | WALKAROUND

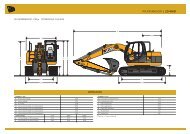

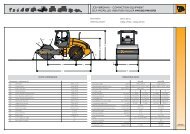

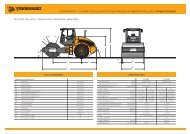

VMT 160: DRUM WIDTH: 800mm – 1000mm (31.5in – 39.4in) OPERATING WEIGHT: 1840kg – 1970kg (4056lb – 4352lb)<br />

VMT 160TSC: DRUM WIDTH: 800mm – 1000mm (31.5in – 39.4in) WORKING WIDTH: 900mm – 1000mm (35.4in – 39.3in) TOTAL SIDE CLEARANCE OPERATING WEIGHT: 1920kg – 1980kg (4056lb – 4365lb)<br />

Dimensions in millimetres (in) <strong>VMT160</strong>-80 <strong>VMT160</strong>-90 <strong>VMT160</strong>-100<br />

A Wheelbase 1350 (53.1) 1350 (53.1) 1350 (53.1)<br />

B Overall width 880 (34.6) 980 (38.6) 1080 (42.5)<br />

C Drum diameter 580 (22.8) 580 (22.8) 580 (22.8)<br />

D Height to top of seat 1600 (63) 1600 (63) 1600 (63)<br />

E Height to top of ROPS 2320 (91.3) 2320 (91.3) 2320 (91.3)<br />

F Ground clearance 290 (11.4) 290 (11.4) 290 (11.4)<br />

G Curb clearance 350 (13.8) 350 (13.8) 350 (13.8)<br />

H Total travel length 2140 (84.2) 2140 (84.2) 2140 (84.2)<br />

J Drum thickness 12 (0.47) 12 (0.47) 12 (0.47)<br />

K Drum width 800 (31.5) 900 (35.4) 1000 (39.3)<br />

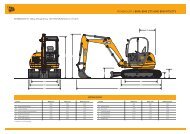

ENGINE<br />

Make KUBOTA<br />

Model D1005 - E3B (EPA Tier IV)<br />

Type 3 cylinder, water-cooled, four-stroke diesel engine<br />

Piston displacement cm 3<br />

1001<br />

Performance kW (hp) 16.8 (22.5)<br />

Operating speed min -1 (rpm) 3000<br />

Starting device Electric motor<br />

Air cleaner Dry cartridge plus safety cartridge<br />

Fuel filter Cartridge<br />

Fuel consumption l/h 2.5<br />

J<br />

F<br />

A<br />

H<br />

C<br />

STATIC DIMENSIONS<br />

D<br />

E<br />

K<br />

B<br />

G<br />

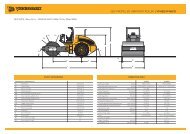

Dimensions in millimetres (in) <strong>VMT160</strong>-80TSC <strong>VMT160</strong>-90TSC<br />

A Wheelbase 1350 (53.1) 1350 (53.1)<br />

B Overall width 980 (38.6) 1080 (42.5)<br />

C Drum diameter 580 (22.8) 580 (22.8)<br />

D Height to top of seat 1600 (63) 1600 (63)<br />

E Height to top of ROPS 2320 (91.3) 2320 (91.3)<br />

F Ground clearance 290 (11.4) 290 (11.4)<br />

G Curb clearance 350 (13.8) 350 (13.8)<br />

H Total travel length 2140 (84.2) 2140 (84.2)<br />

J Drum thickness 12 (0.47) 12 (0.47)<br />

K Drum width 900 (35.4) 1000 (39.3)<br />

PROPULSION<br />

Hydrostatic with variable displacement pump and fixed displacement motors with direct drive to both drums = double drum drive.<br />

EXCITER DRIVE<br />

Electrically controlled hydrostatic direct drive on both drums for double vibration or single vibration front or rear, AVC (automatic<br />

vibration control).<br />

Single-shaft circular exciter.<br />

EXCITER<br />

<strong>VMT160</strong> | SPECIFICATION

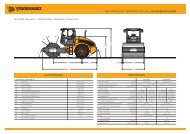

<strong>VMT160</strong>-80 <strong>VMT160</strong>-90 <strong>VMT160</strong>-100<br />

Nominal weight kg (lb) 1683 (3711) 1743 (3843) 1813 (3998)<br />

Operating weight (CECE) kg (lb) 1840 (4056) 1900 (4189) 1970 (4343)<br />

Maximum operating weight kg (lb) 1910 (4211) 1970 (4343) 2040 (4497)<br />

Working width mm 800 900 1000<br />

Operating linear load kg/cm (lb/in) 11.5 (64.4') 10.6 (59') 9.9 (55.16')<br />

Exciter frequency Hz 50 … 66 50 …66 50 …66<br />

Nominal amplitude mm 0.5 0.5 0.5<br />

Centrifugal force (each drum) kN 9.2 … 18 9.2 … 18 9.2 … 18<br />

Max. Working speed km/h 0 …9 0 …9 0 …9<br />

Drum offset left / right – manual (option) mm 65 65 65<br />

Steering angle ° ±30 ±30 ±30<br />

Oscillation angle ° ±8 ±8 ±8<br />

Inner turning radius mm 2120 2070 2020<br />

Gradeability with vibration up to ° (%) 17 (30) 17 (30) 17 (30)<br />

Gradeability without vibration up to ° (%) 22 (40) 22 (40) 22 (40)<br />

STEERING SYSTEM<br />

Servo assisted, maintenance free center articulation with oscillation facility, front and rear winching points.<br />

SERVICE CAPACITIES<br />

Fuel litres 45<br />

Sprinkler water litres 125<br />

BRAKING SYSTEM<br />

Service brake: Hydrostatic propulsion system.<br />

Parking brake: Hydraulically released brake on both drums (SAHR).<br />

SPRINKLER/SCRAPER<br />

Pressurized sprinkling system, spring loaded retractable scraper (two each drum), changeable nozzles, multiple water filtering.<br />

OPERATING DATA<br />

Working lights, backup alarm, safety switch in operators seat.<br />

ELECTRICAL SYSTEM<br />

Voltage V 12<br />

Battery capacity Ah 45<br />

Alternator A 40<br />

DRIVERS STAND/INSTRUMENTS<br />

Fuel, battery charging current, sprinkler system, parking brake, hour meter, engine oil pressure, air filter condition, hydraulic oil<br />

level and temperature, water level indicator, cup holder, comfortable adjustable operator seat.<br />

OPTIONS<br />

<strong>VMT160</strong> | SPECIFICATION<br />

<strong>VMT160</strong>-80TSC <strong>VMT160</strong>-90TSC<br />

Nominal weight kg (lb) 1763 (3887) 1823 (4020)<br />

Operating weight (CECE) kg (lb) 1920 (4233) 1980 (4365)<br />

Maximum operating weight kg (lb) 1990 (4387) 2050 (4519)<br />

Working width mm 900 1000<br />

Operating linear load kg/cm (lb/in) 10.6 (64.2') 9.9 (61.6')<br />

Exciter frequency Hz 50 …66 50 …66<br />

Nominal amplitude mm 0.5 0.5<br />

Centrifugal force (each drum) kN 9.2 … 18 9.2 … 18<br />

Max. Working speed km/h 0 …9 0 …9<br />

Drum offset left / right – manual (option) mm 65 65<br />

Steering angle ° ±30 ±30<br />

Oscillation angle ° ±8 ±8<br />

Inner turning radius mm 2070 2020<br />

Gradeability with vibration up to ° (%) 17 (30) 17 (30)<br />

Gradeability without vibration up to ° (%) 22 (40) 22 (40)<br />

ROPS (standard at CE), foldable ROPS, Total Side Clearance (TSC) operation (160-80 & 160-90), drum offset, lights for road<br />

traffic, flashing beacon, battery isolating switch, central lifting eye, driver seat with arm rests.

<strong>JCB</strong> | LIVELINK<br />

Your machine – working efficiently,<br />

secure and in good health<br />

JCb LiveLink and Guardian are<br />

the key to all three<br />

As part of our dedication to looking at new, innovative ways to help you get<br />

the most out of your machine, our latest development is <strong>JCB</strong> LiveLink: an<br />

advanced machine monitoring system that enables you to better protect<br />

your investment and accurately monitor and improve machine performance.<br />

<strong>JCB</strong> LiveLink is a software system that enables <strong>JCB</strong> owners to monitor<br />

and manage their machines remotely. All you need is a PC connected to<br />

the internet. The LiveLink computer is built into the machine where it<br />

collects information from a number of sensors. This information is sent,<br />

using mobile communications technology, to <strong>JCB</strong>’s secure data centre.<br />

Machine management information is then displayed to users via the<br />

LiveLink website, by email or via mobile phone.<br />

By providing you with information on the usage and productivity of your<br />

fleet, <strong>JCB</strong> LiveLink enables you to keep track of each machine’s efficiency,<br />

ensuring that you get the best value for money possible.<br />

By providing information on the location, movement and activity of<br />

machines, the system can also assist in ensuring machines are operated<br />

at the correct times and helps to protect them from theft. And, <strong>JCB</strong><br />

LiveLink helps machine owners to confirm that their machines are well<br />

maintained and in good health without having to travel around work sites<br />

inspecting machines.<br />

In response to increasing concerns regarding machine security, we now<br />

also offer <strong>JCB</strong> Guardian as an option on every new <strong>JCB</strong> machine. <strong>JCB</strong><br />

Guardian is a package of theft protection and monitoring systems that<br />

includes LiveLink telemetry along with *CESAR identification, immobiliser<br />

technology and a host of optional locks and guards. It’s your peace of mind<br />

solution that can also result in considerable insurance premium savings.<br />

*Territory specific

<strong>JCB</strong> Assetcare<br />

Flexible aftercare solutions<br />

JCb Assetcare is a range of flexible service options designed<br />

to ensure you get the very highest standards of machine<br />

servicing, no matter what your budget. It guarantees you the<br />

optimum level of aftersales support, with highly skilled,<br />

factory-trained engineers using genuine JCb parts and<br />

lubricants to maintain maximum machine performance.<br />

This allows your machine to be covered to maximise<br />

uptime and profitability throughout its operating life.<br />

“For complete peace of mind<br />

and cost predictability<br />

choose <strong>JCB</strong> Assetcare.”<br />

<strong>JCB</strong> Assetcare offers you the following options, which can be tailor-made<br />

to meet your specific requirements including excellence as standard:<br />

For complete peace of mind and total budget predictability, your <strong>JCB</strong><br />

dealer can offer a Full Repair and Maintenance package, with a fixed<br />

monthly sum covering all regular maintenance and necessary repairs<br />

including Flexicare for excavators and wheeled loading shovels, to give a<br />

pay by the hour alternative.<br />

A JCb Service Agreement allows you to plan and manage your maintenance<br />

budget over a period of hours, or years of machine use, as determined by<br />

you. The price is maintained for the duration of the agreement and includes<br />

all parts, lubricants, labour and travel to maximise your machine performance.<br />

JCb Sure Price Service (pay as you go) includes all genuine <strong>JCB</strong><br />

lubricants, filters, greases and other parts and is carried out as you require<br />

it. The all-inclusive price also covers labour, 100 point check and any<br />

travel. Service intervals are hours based (usually every 500 hours) and no<br />

prior agreement is required; simply advise your dealer when the machine<br />

reaches the recommended service interval for great value for money.<br />

JCb Machinery Protection Plan protects you against any unexpected<br />

failure for up to 2, 3, 4 or 5 years or up to 10,000 hours depending on<br />

machine type. You can take up a Machinery Protection Plan at any time during<br />

the first three months of ownership, and the package is transferable on the<br />

initial machine sale. Coverage options are 500, 1000, 1500 or 2000 hours<br />

per year (model dependent).<br />

JCb Driveline Protection Plan – sign up to a Service Agreement on<br />

Backhoe or Loadall mechanical transmission machines and get FREE<br />

Driveline Protection for every 1,000 hours you commit to (covers Engine,<br />

Transmission and Axle).<br />

For the full terms and conditions of the above programmes please speak to your local dealer.<br />

<strong>JCB</strong> | ASSETCARE

<strong>JCB</strong> | A FEW WORDS<br />

A few words about <strong>JCB</strong><br />

A groundbreaking, world class<br />

family business with a commitment<br />

to supporting our customers and<br />

protecting the environment<br />

A family company on a global scale. <strong>JCB</strong> is no ordinary<br />

company. From the dreams of one man, Joseph Cyril Bamford, we<br />

have grown into the world’s largest privately owned construction<br />

equipment company. Since 1945, the same attention to detail, passion<br />

for progress and family spirit has taken us from strength to strength.<br />

Nowadays <strong>JCB</strong> operates across five continents, manufacturing at 18<br />

factories in the UK, Brazil, Germany, China, North America and India.<br />

With 1,500 dealer depots selling and supporting our products in over<br />

150 countries, we are the global market leader for backhoe loaders<br />

and telescopic handlers.<br />

A history of world-class innovation. Our business has always<br />

been driven by innovation, using only the most advanced technology,<br />

meticulous design, precision engineering and rigorous testing. Evidence<br />

of this commitment to innovation is illustrated in our revolutionary <strong>JCB</strong><br />

Dieselmax engine. Having grabbed the headlines when it smashed the<br />

world diesel land speed record at 350.092mph, it is now providing<br />

our customers with tomorrow’s performance today.<br />

Doing things more efficiently, more sustainably. Since 2007<br />

we have reduced our carbon emissions by 20%. We are continually<br />

working to further reduce the carbon footprint of our operations<br />

and, in partnership with our suppliers, our whole supply chain. We<br />

are also committed to designing our products to be sustainable during<br />

manufacturing, over the life of the machine and through end-of-life<br />

recycling. Our new Eco machines, for example, offer significant fuel and<br />

carbon savings; an average of 16% on the Eco backhoes and 22% on<br />

the 8085 Eco.

The best back-up in the business<br />

Whether we’re providing you with<br />

support, parts or finance, we aim for<br />

100% satisfaction. It’s all part of our<br />

promise to put you, the customer, first<br />

Manufacturing Facilities<br />

Dealers<br />

Parts Distribution Centres<br />

Wherever you are, we are. Our mission to provide world-class<br />

support and deliver 100% satisfaction reaches into more than 1,500<br />

dealer depots, spanning 150 countries across five continents. The<br />

aim? To bring you global expertise at a local level. We truly believe no<br />

other manufacturer does more to understand the subtle differences<br />

between one region of the world and another. It’s a degree of<br />

attention that we maintain at every level of the company and an<br />

assurance to our customers that wherever they are in the world, <strong>JCB</strong><br />

will fulfil their needs.<br />

Trust the genuine article. At the heart of the support network is<br />

our impressive World Parts Centre, a state-of-the-art facility operating<br />

24/7 to dispatch more than a million genuine parts and attachments<br />

every week to our dealers and international distribution centres.<br />

Because we understand the need to minimise downtime, we utilise<br />

the latest logistics and warehouse management systems and have<br />

committed to an ‘Anywhere in 24 hours’ strategy.<br />

Keeping you up and running. Just as important as genuine <strong>JCB</strong><br />

parts are the people who fit and maintain them. Our <strong>JCB</strong>-trained<br />

technicians in all of those 1,500-plus dealer depots provide excellent,<br />

expert customer care, whether it’s routine servicing or something<br />

more urgent. If there is an emergency breakdown situation, we<br />

need to act fast. This is why all our dealers operate their own fleets<br />

of support vehicles, enabling parts to be delivered quickly and fitted<br />

expertly, and fulfilling our promise to keep our customers working.<br />

<strong>JCB</strong> | bACK-UP<br />

Maximising earning potential. We grow as our customers grow.<br />

That’s why, at <strong>JCB</strong>, we are committed to offering expert financial<br />

advice and support to help customers maximise their earning potential.<br />

Finance options* are available for new and used machinery, all part<br />

of our dedication to helping customers preserve their working capital<br />

while spreading costs in the most effective and tax-efficient way.<br />

And as well as financial help, we are also happy to offer <strong>JCB</strong> Insurance.*<br />

We specialise in construction and industrial insurance and in offering<br />

Insurance Premium Finance facilities.<br />

* Please check individual countries for available services.

<strong>JCB</strong> Vibromax GmbH<br />

Schäferberg 1<br />

06466 Gatersleben, Germany<br />

Tel: +49 (0) 39482 -700<br />

Fax: +49 (0) 39482 -70102<br />

<strong>JCB</strong> Vibromax GmbH<br />

Graf-Zeppelin-Str, 8<br />

51157 Köln, Germany<br />

Tel: +49 (0) 2203 9253-0<br />

Fax: +49 (0) 2203-9253-270<br />

www.jcbvibromax.de<br />

<strong>JCB</strong> reserves the right to change specification without notice. Some machines shown within this brochure are fitted with<br />

optional equipment which may vary between territories. The <strong>JCB</strong> logo is a registered trademark of J C Bamford Excavators Ltd.<br />

Printed in the UK on paper made from sustainable forests. The pulp used in the manufacture of this paper is made from<br />

renewable timber produced on a fully sustainable basis, and is bleached without the use of chlorine gas (ECF – Elemental<br />

Chlorine Free). This paper is suitable for recycling. 9999/5296 03/11 Issue 5